Automatic calibration method of treatment machine for accurate liquid adding and constant volume

An automatic calibration and liquid processing technology, applied in the field of laboratory instruments, can solve the problems of low efficiency, repetitive and cumbersome manual processing, and errors in operation, and achieves the effect of good effect, repetitive and cumbersome solution, and process standardization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The automatic calibration method of the liquid processor for precise liquid addition and constant volume in this embodiment includes the following steps:

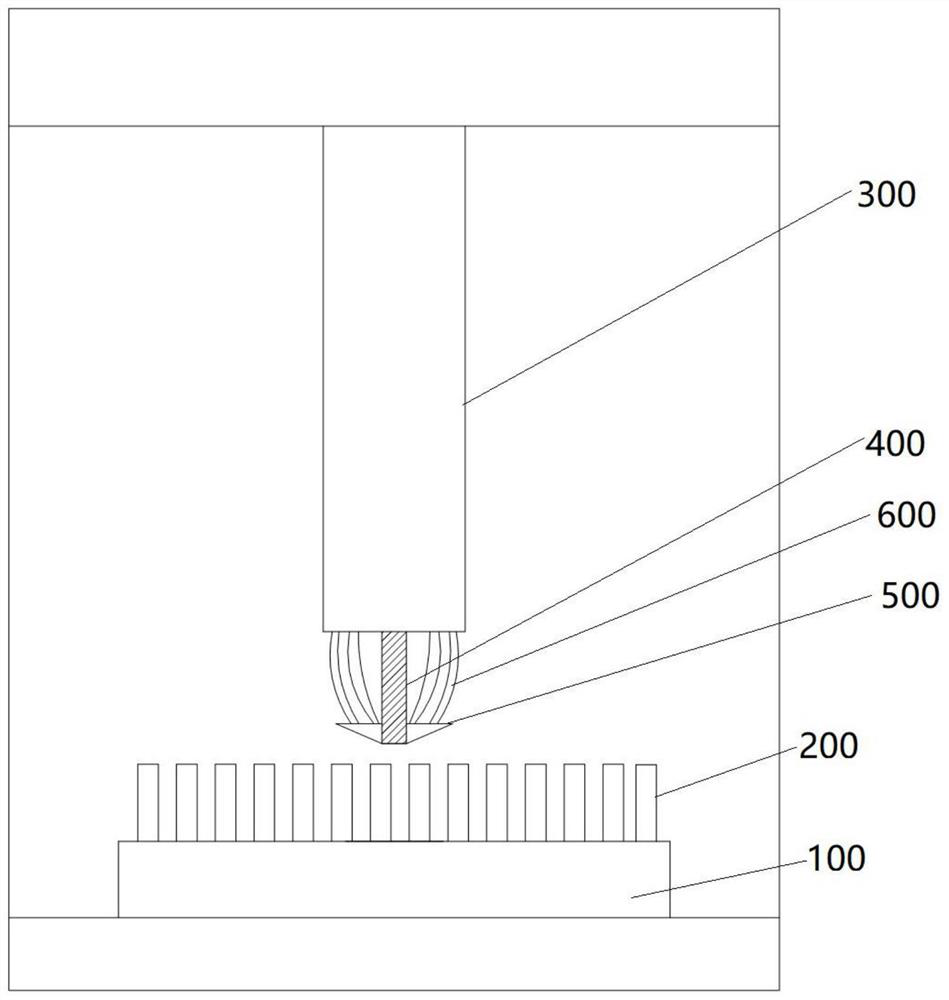

[0071] (A) pretreatment: such as image 3 As shown, the porous test tube position fixing seat 100 is installed below the liquid processor, and multiple rows of test tubes 200 are placed above the porous test tube position 100, and the liquid adding arm 300 is arranged above the multiple rows of test tubes 200. The bottom of the liquid-filling arm 300 is provided with a liquid-filling part, and the liquid in the liquid-filling part is quantitatively driven by a metering pump; wherein the liquid-filling part includes an ultrasonic liquid level sensor 400, a liquid pipeline fixing seat 500 and The liquid processing pipeline 600 fixed on the liquid pipeline fixing seat 500;

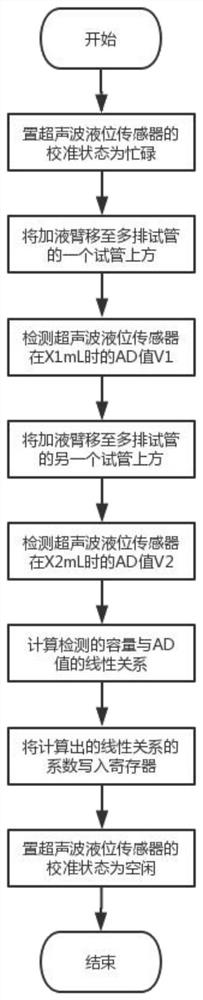

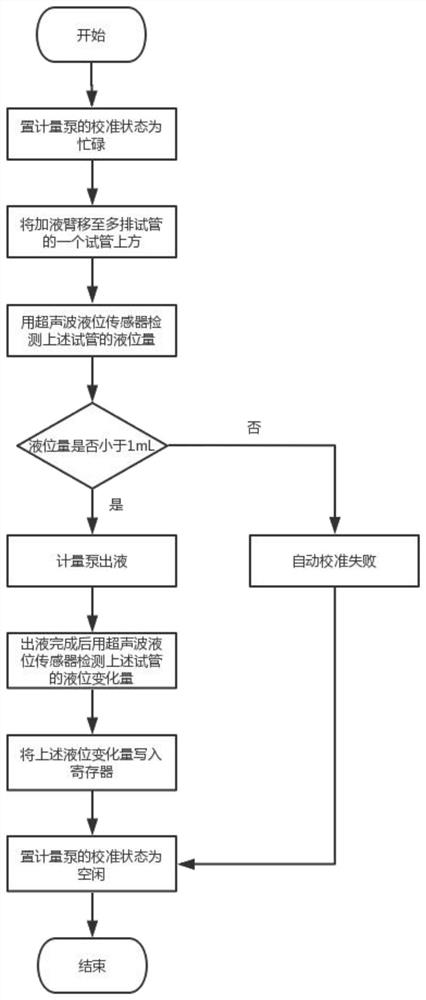

[0072] It should be reminded that, when adding liquid to the multi-row test tubes 200, it is necessary to calibrate the accuracy of the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com