Oil composition for frying hot pot condiment

A kind of oil composition and oil technology, applied in the direction of edible oil/fat, application, food science, etc., can solve the problem of poor quality of hot pot oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

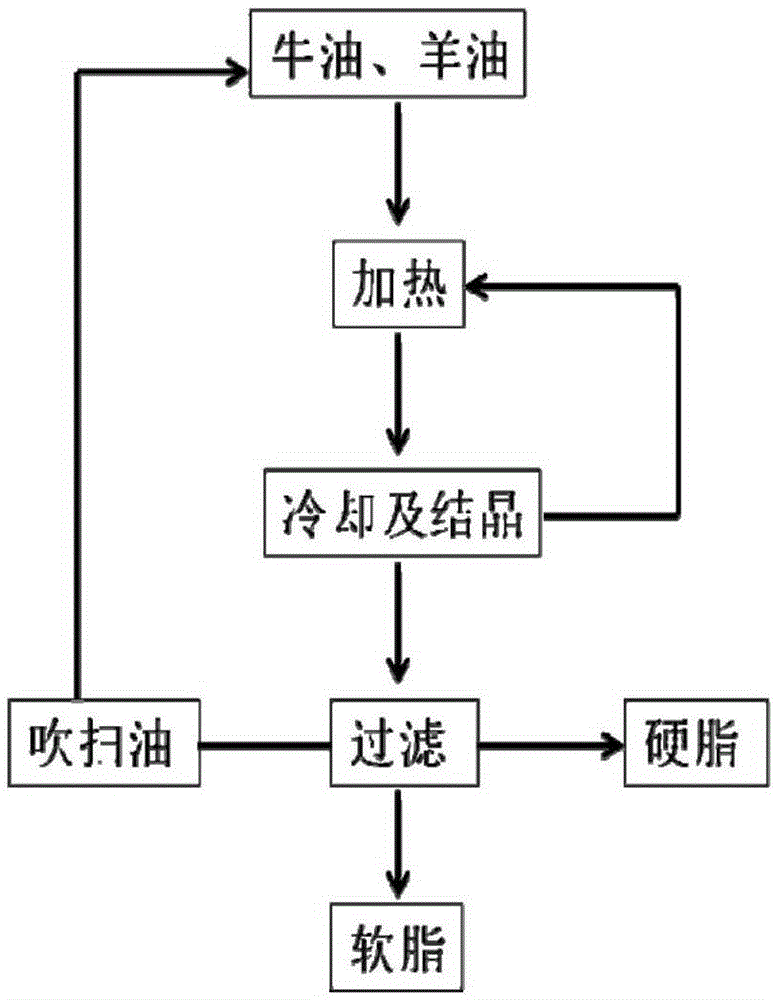

[0111] The high-melting point components in tallow and sheep oil obtained after boiling at high temperature are fractionated.

[0112] First, take 50% sirloin oil and 50% tripe oil raw fat as raw materials, put the chopped fat into a stainless steel cooking pot, use heat conduction oil as a medium for heat conduction, and keep stirring continuously during the heating process to prevent local overheating Burnt smell. Start heating at 20°C, slowly raise the temperature, reach 190°C after 60 minutes, maintain at the end point temperature for 5 minutes, and stir at a speed of 36 r / min to obtain fire-refined tallow.

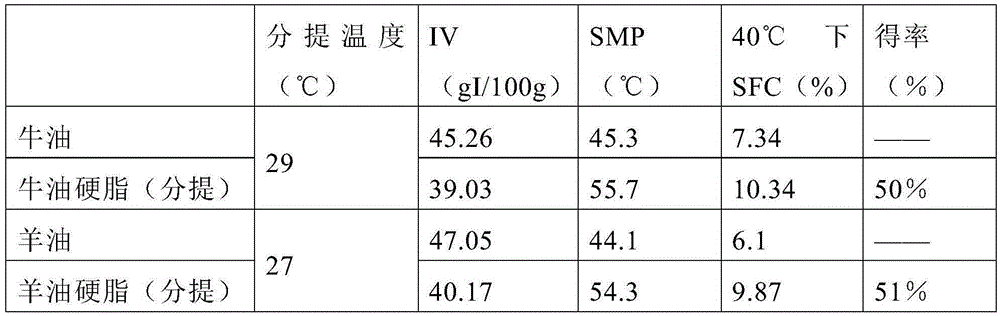

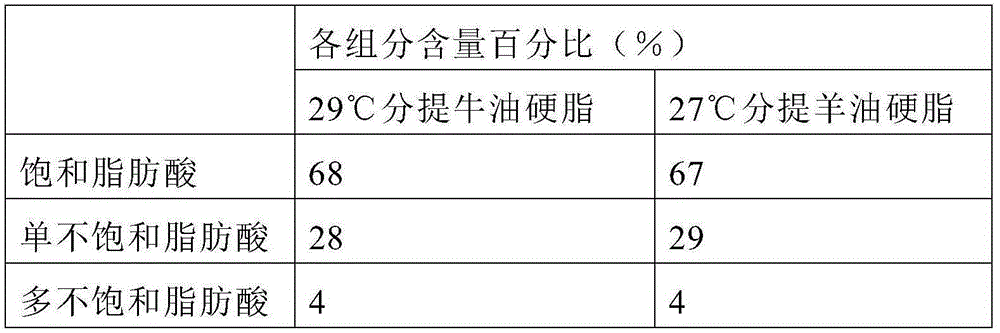

[0113] Carry out dry fractionation of the above-mentioned fire-refined butter, dissolve the fire-refined butter into a liquid state by electric heating before the fractionation process, heat to 72°C, and keep at this temperature for half an hour to destroy possible irregular crystals . Place it in a water bath to cool, and monitor the cooling rate of the butter with...

Embodiment 2

[0123] Tea polyphenol palmitate is a natural antioxidant that is allowed to be added (GB 2760, the maximum addition amount is 600ppm), and it has good stability to animal fats; tocopherol is not only an antioxidant but also a good nutrient.

[0124] Carry out dry fractionation of the fire-refined tallow in Example 1, dissolve the fire-refined tallow into a liquid state by electric heating before the fractionation process, heat to 75°C, and keep at this temperature for half an hour to destroy possible Irregular crystals. Place it in a water bath to cool, and monitor the cooling rate of the butter with a temperature controller (the cooling rate is controlled at 2° C. / h). Stop cooling when the temperature drops to 28°C. After standing for crystallization for 6 hours, use a diaphragm filter press to filter the crystallized butter. The initial pressure is 0.2MPa. Increase the pressure. When the liquid oil can hardly be squeezed out, the pressure of the diaphragm frame is removed, ...

Embodiment 3

[0138] Carry out dry fractionation of the fire-refined tallow in Example 1, dissolve the fire-refined tallow into a liquid state by electric heating before the fractionation process, heat to 73°C, and keep at this temperature for half an hour to destroy possible Irregular crystals. Place it in a water bath to cool, and monitor the cooling rate of the butter with a temperature controller (the cooling rate is controlled at 2° C. / h). Stop cooling when the temperature drops to 30°C. After standing for 6 hours to crystallize, use a diaphragm filter press to filter the crystallized butter. The initial pressure is 0.2MPa. Increase the pressure. After 9 minutes, the pressure rises to 0.9MPa. When the liquid oil can hardly be squeezed out, the pressure of the diaphragm frame is removed, and the filter cake is the extracted hard fat. The resulting filter cake has a melting point of 58.1° C. and an iodine value of 34.5 gI / 100 g. The hardened butter obtained after fractionation still ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com