A fully sealed high-transparency glass extraction device and extraction method thereof

A high-transparency glass and extraction device technology, applied in the extraction field, can solve the problems of limited settling space in the clarification chamber, failure to accurately control the phase separation situation, self-adjusting phase flow rate, and high viscosity of the mixed phase, so as to eliminate potential safety hazards in production , Optimize the extraction operation environment, the effect of variable series and large elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

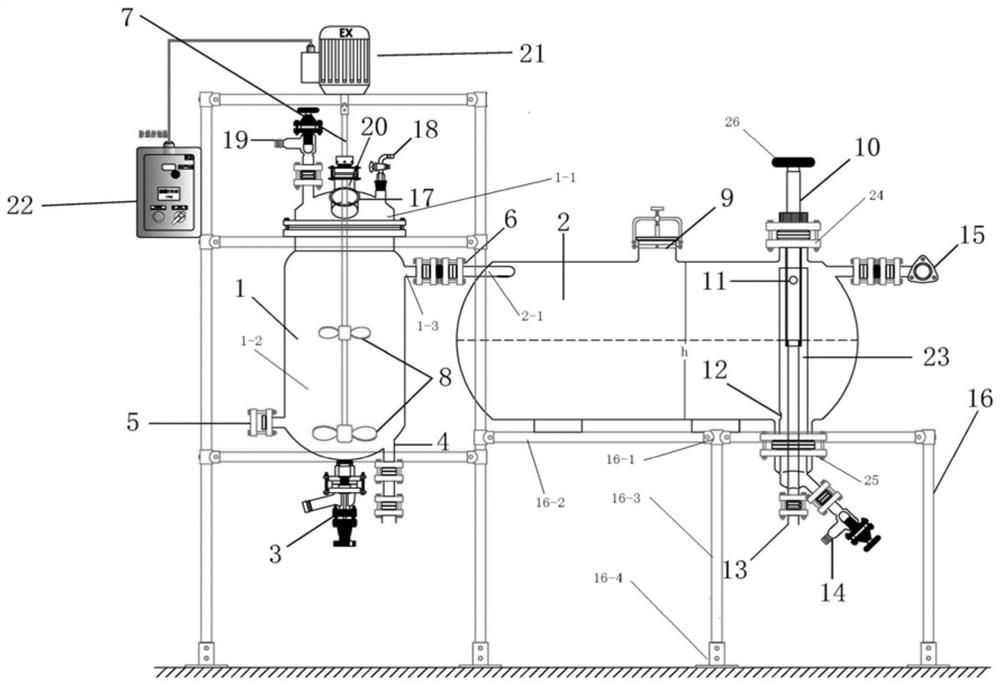

[0034] The following structural drawings further illustrate a fully transparent special glass extraction tank of the present invention.

[0035] Such as figure 1 As shown, a fully sealed high-permeability glass extraction device of the present invention includes a monomer vertical mixing chamber 1, a monomer mixing and stirring device, a monomer horizontal clarification chamber 2 and a mixed phase overflow pipe 6;

[0036] The monomer mixing and stirring device includes a motor control box 22, a frequency conversion motor 21, a connecting shaft 7 and a stirring paddle 8,

[0037] Wherein, the monomer vertical mixing chamber 1 is composed of a tank body 1-1 and a tank cover 1-2, and the bottom of the tank body 1-1 is provided with an organic phase liquid inlet 5, an aqueous phase liquid inlet 4 and An emptying valve 3, the upper end of the tank body 1-1 is provided with an overflow port 1-3, and the tank cover 1-2 is provided with a shaft hole 20, a cleaning port 18, a spare h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com