Filter element and multi-stage composite filter element formed by same

A composite filter element and filter element technology, which is applied in the field of filter elements, can solve the problems of limited filter element length, super-long filter elements cannot meet fast docking, accurate positioning, convenient installation, and affect production efficiency, so as to ensure the purification effect and the overall straightness of the product. space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

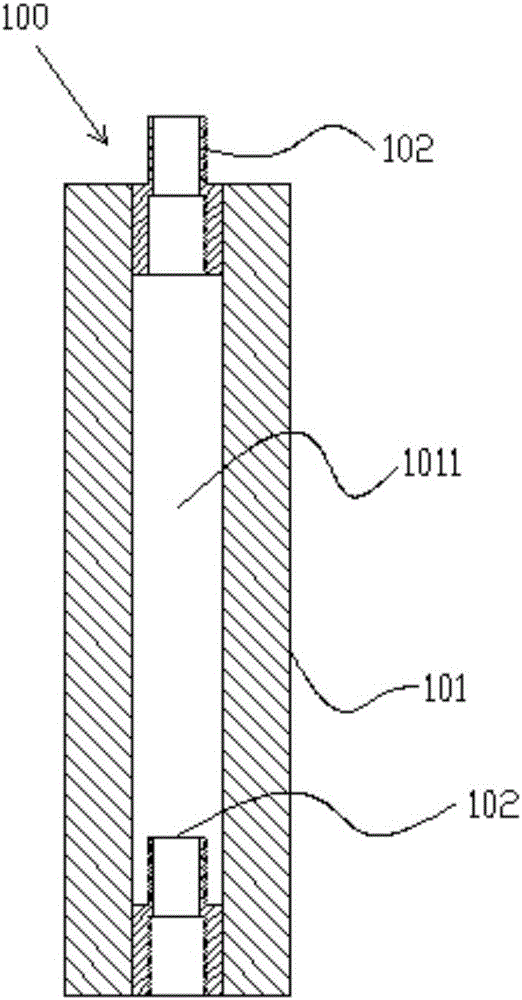

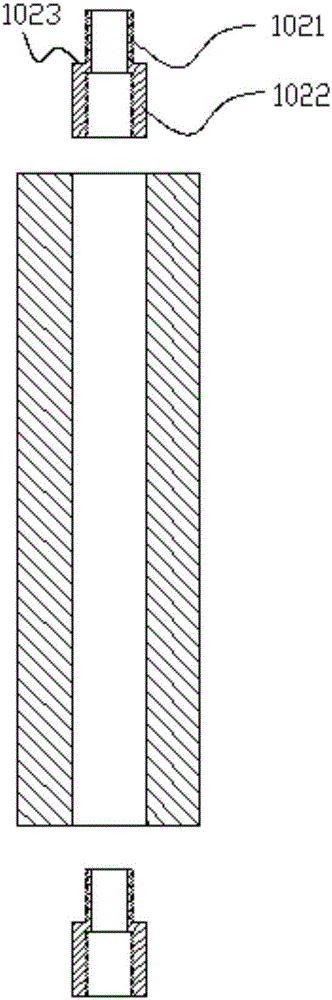

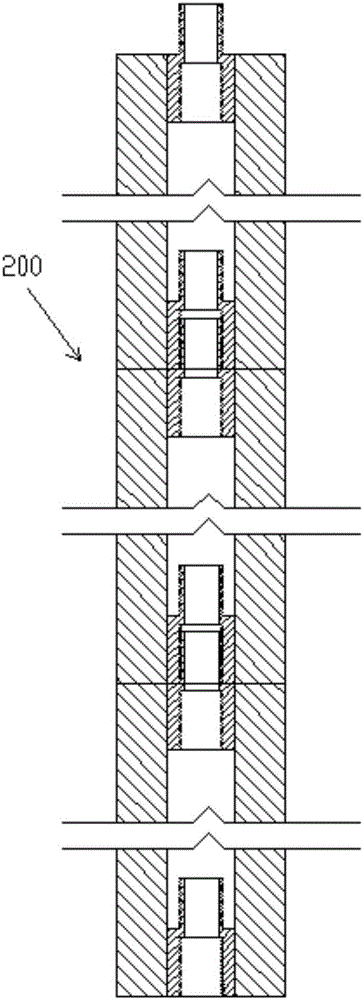

[0030] Embodiment: a kind of filter element 100, as figure 1 and figure 2 As shown, it includes a filter body 101 and a connector 102. The filter body 101 is a cylindrical filter body with a cavity 1011 in the middle, and the cavity 1011 is a through hole extending from the lower end of the filter body 101 to the upper end. , the connecting piece 102 has two and is respectively embedded in the upper end and the lower end of the filter body 101, the connecting piece 102 is a stepped tubular connecting piece formed by connecting the upper tube 1021 and the lower tube 1022, and the The inner diameter of the lower tube 1022 matches the outer diameter of the upper tube 1021, the outer diameter of the lower tube 1022 matches the cavity 1011 of the filter body 101, and is located on the upper end of the connector 102 at the upper end of the filter body 101. The tube 1021 protrudes from the upper end of the filter element body 101 .

[0031] In this embodiment, the connectors 102 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com