Automobile side wall outer plate drawing die provided with auxiliary drawing male die

A drawing die, automobile side technology, applied in the direction of forming tools, manufacturing tools, vehicle parts, etc., can solve problems such as reducing production efficiency, parts cracking or wrinkling, and drawing bead wear, etc., to improve production efficiency and deformation. Sufficient and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further elaborate the technical means adopted by the present invention to achieve the desired invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features according to the present invention are described in detail as follows:

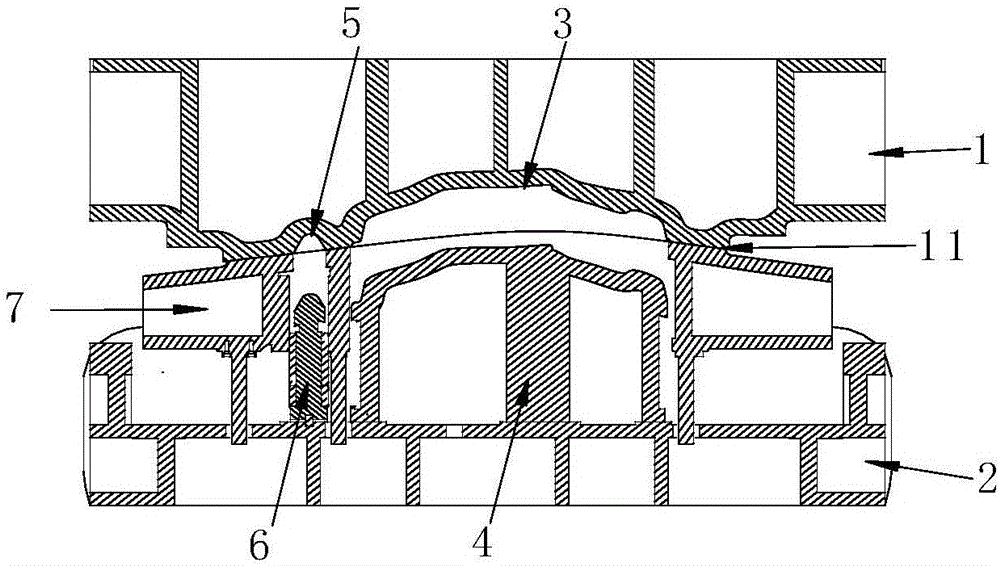

[0032] Such as image 3 As shown, the automobile side panel outer panel drawing die with auxiliary drawing punch 6 according to the present invention includes an upper die base 1, a lower die base 2 and a blank holder 7, and the upper die base 1 is provided with a drawing The drawing die 3, the lower die base 2 is correspondingly provided with a drawing punch 4 matched with the drawing die 3, the drawing punch 4 is arranged inside the blank holder 7 and It is slidably connected with the blank holder ring 7. In order to prevent the sheet material 11 from being pulled apart during the drawing forming process, and at the same time make the deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com