Machine tool with mistake-proofing system

An error-proofing system and machine tool technology, applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of unqualified products and complicated operations, and achieve the purpose of preventing the processing time from being too short and being a good warning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

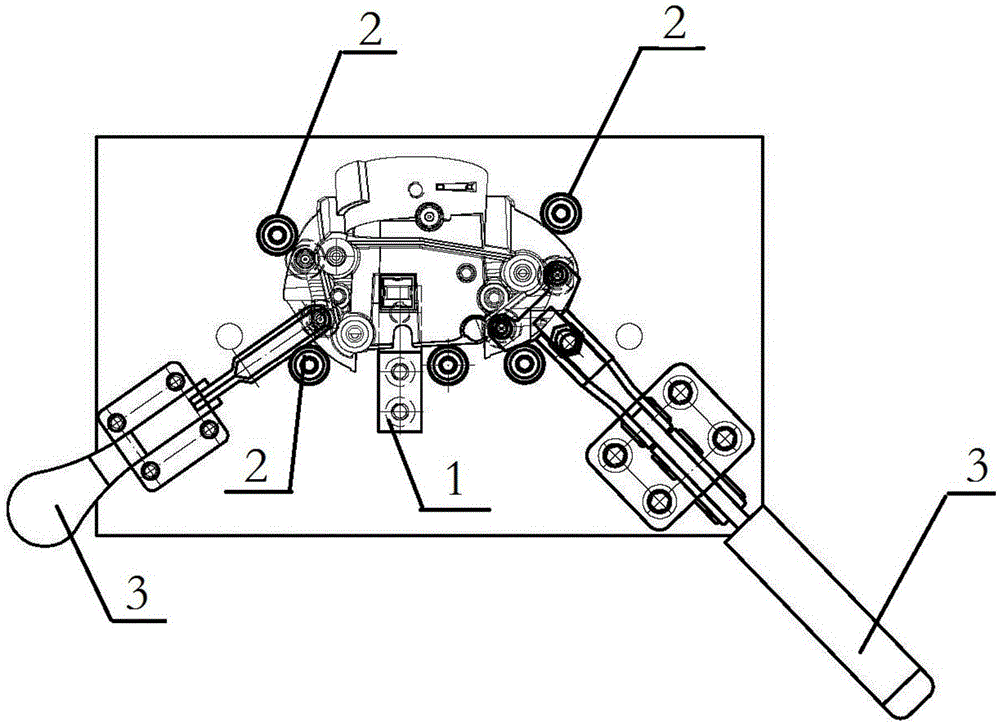

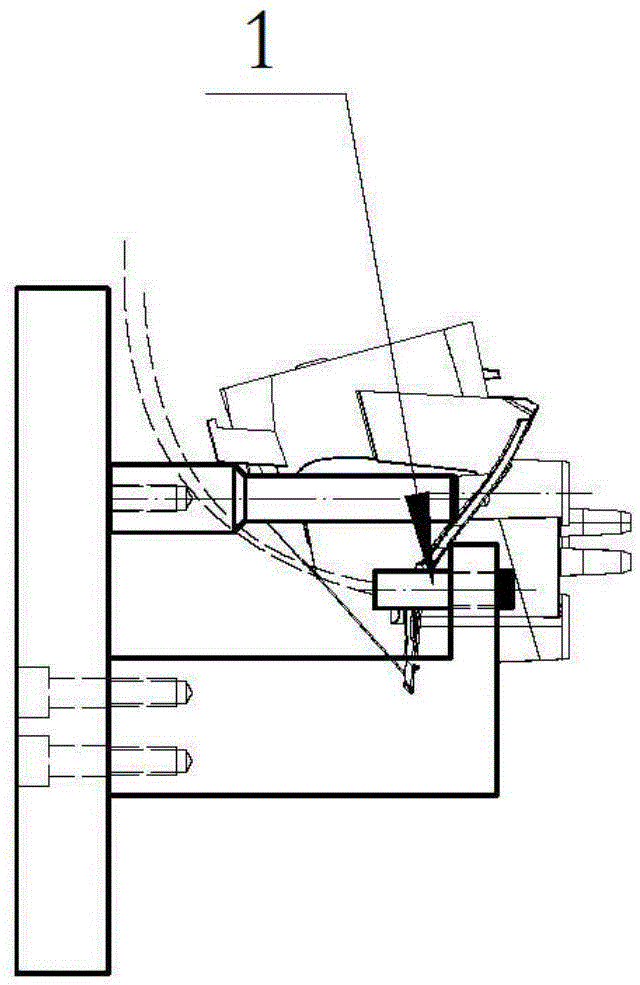

[0025] Such as figure 1 , figure 2 As shown, a machine tool with an error prevention system includes an instruction panel, a jig and an error prevention system. The instruction panel is connected to the error prevention system. There are multiple instruction buttons on the instruction panel. After pressing the corresponding instruction button Commands such as start-up, shutdown, and processing can be issued. The error-proof system includes a sensor 1, an alarm and a controller. The sensor 1 and the alarm are respectively connected to the controller, and the sensor 1 is arranged on the machine tool. When the product to be processed is placed in place, it enters the sensing area of sensor 1. When the controller receives the processing instruction from the command panel and sensor 1 senses the product to be processed, the controller controls the machine tool to process the product. After the product leaves the sensing area, sensor 1 resets ; If the sensor 1 does not receive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com