Clamping mechanism and heat shrink tubing positive companding device using same

A heat-shrinkable tube, positive compression expansion technology, applied in the field of heat-shrinkable tube processing equipment, can solve the problems of inconsistent axial length of heat-shrinkable tubes, uneven heating, heat-shrinkable tube fractures, etc., to reduce energy consumption, The effect of uniform heating and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

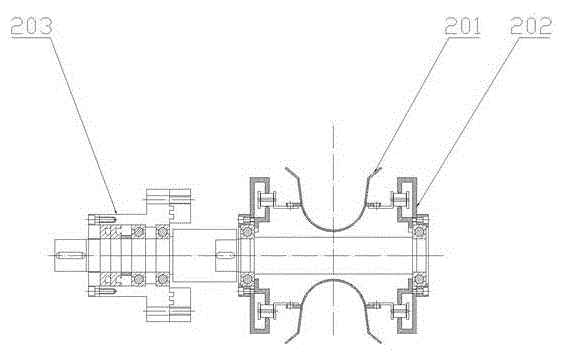

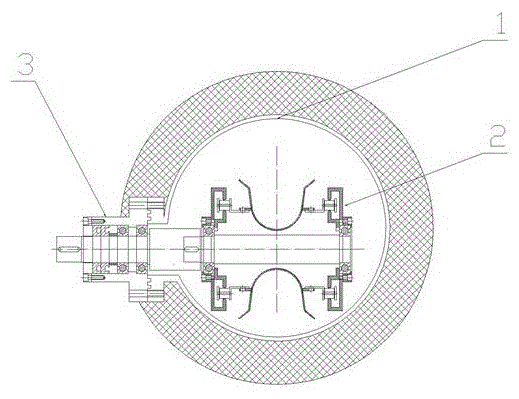

[0024] see figure 1 , the present invention provides a clamp mechanism 2, comprising several U-shaped clamps 201, a connection mechanism 202 connecting the clamps 201, and a transmission mechanism 203 for driving the connection mechanism 202, and in the clamp mechanism 2, several clamps 201 are arranged in parallel It is divided into upper and lower layers, the U-shaped opening of the upper layer is upward, and the U-shaped opening of the lower layer is downward. Each clamp 201 moves reciprocatingly under the action of the connecting mechanism 202 .

[0025] see figure 1 , in an embodiment of the clamp mechanism 2 of the present invention, horizontal steel bars are welded on the outer sides of each clamp 201. After the L-shaped steel bars in the connecting mechanism 202 are threaded, each clamp 201 is connected in parallel, and the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com