Magnet surface treatment device and system, and surface treatment method of neodymium-iron-boron magnet

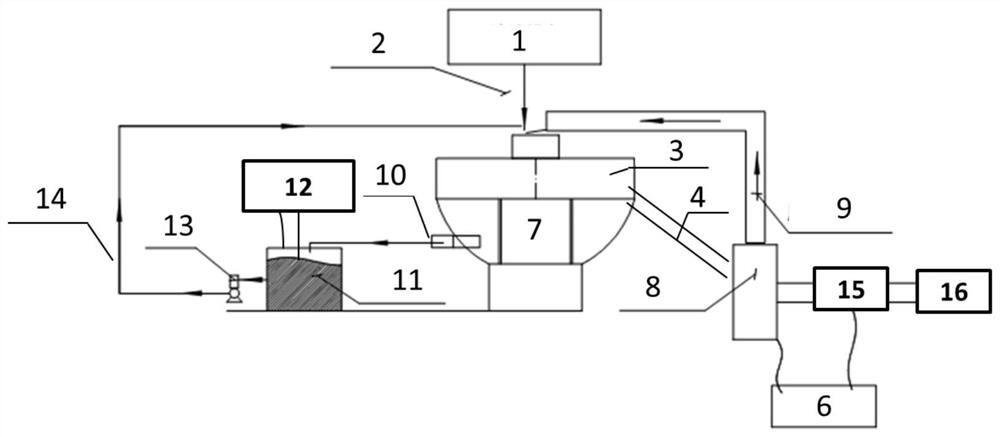

A surface treatment device and surface treatment technology, which is applied in the field of surface treatment of magnets of different sizes and shapes in batches on automatic lines, surface treatment of NdFeB magnets, and the field of magnet surface treatment devices, which can solve the problem of reducing surface treatment and failing to meet the requirements of NdFeB magnets. Magnet surface treatment requirements, difficult to improve surface treatment efficiency and other issues, to achieve the effect of no patch marks, good cleaning and passivation film formation quality, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

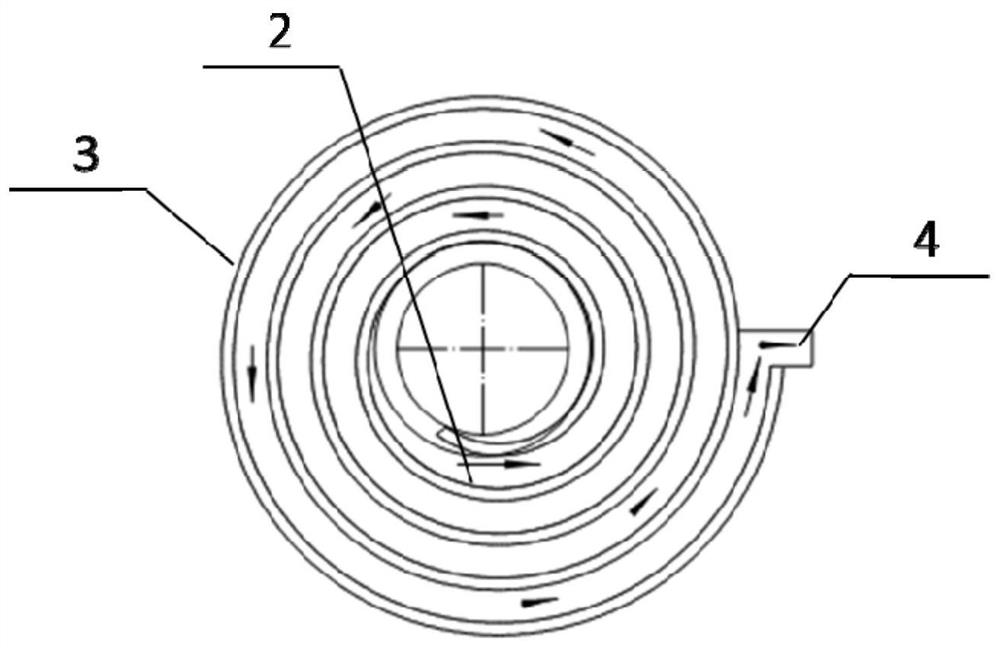

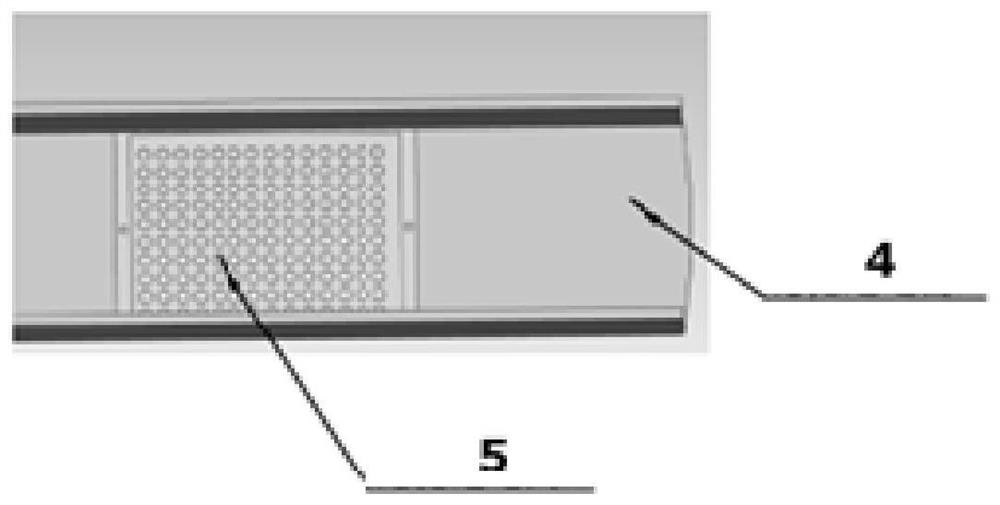

[0090] The above-mentioned surface treatment method is used to carry out phosphating treatment on the magnet, wherein the channel of the spiral rotary channel 3 is a back-shaped polyurethane (the cross-sectional view is as shown in Fig. Figure 4As shown in the middle right figure), the slope is 15°, the magnet to be treated is a cuboid, and the unit weight is 396g; the treatment liquid is a zinc-based phosphating liquid, the treatment temperature is 55°C, and the flow rate of the phosphating liquid is 40L / min , the transmission medium is spherical glass beads with a diameter of 8-10mm, the mass ratio of the magnet to the transmission medium is 6:1, and the residence time of the magnet in the channel is 10min. After screening, the magnet enters the water washing tank and the ultrasonic cleaning tank for Cleaning, and finally blow-drying and drying, the magnet is first blown with hot air at a certain temperature, and then dried at 105°C for 30 minutes to obtain a magnet after pho...

Embodiment 2

[0093] Adopt the above-mentioned surface treatment method to carry out phosphating treatment to the magnet, wherein, the channel of the said spiral rotary channel 3 is the polyurethane of back shape, and the slope is 15°; The magnet to be treated is a C-shaped tile, with a unit weight of 3.5g; The solution is a zinc-based phosphating solution, the treatment temperature is 55°C, the flow rate of the phosphating solution is 30L / min, the transmission medium is spherical zirconia with a diameter of 3-5mm, and the mass ratio of the magnet to the transmission medium is 10:1 , The magnet stays in the channel for 10 minutes. After screening, the magnet enters the water washing tank and the ultrasonic cleaning tank for cleaning, and finally blows and dries the magnet. drying to obtain a phosphating-treated magnet.

[0094] For the phosphating film on the surface of the magnet after phosphating treatment, EDS-7200 energy spectrometer was used to analyze the surface appearance and compos...

Embodiment 3

[0096] The above-mentioned surface treatment method is used to carry out silane conversion treatment on the magnet, wherein the channel of the spiral rotary channel 3 is U-shaped polyurethane (the cross-sectional view is as follows Figure 4 As shown in the middle left picture), the slope is 30°, the magnet to be treated is a cuboid, and the unit weight is 15.7g; the treatment liquid is a silane conversion liquid, the treatment temperature is normal temperature, and the flow rate of the conversion liquid is 35L / min. It is a spherical glass bead with a diameter of 5-7mm. The mass ratio of the magnet to the transmission medium is 5:1. The residence time of the magnet in the channel is 3min. Blow the magnet with hot air at a certain temperature, and then dry it at 105° C. for 30 minutes to obtain a magnet after silane conversion treatment.

[0097] For the conversion film on the surface of the magnet after the silane conversion treatment, the surface appearance and composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com