Distributor with circular outlet

An outlet distributor, circular technology, applied in the field of fluid distributors, can solve the problem of inability to realize co-extrusion in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

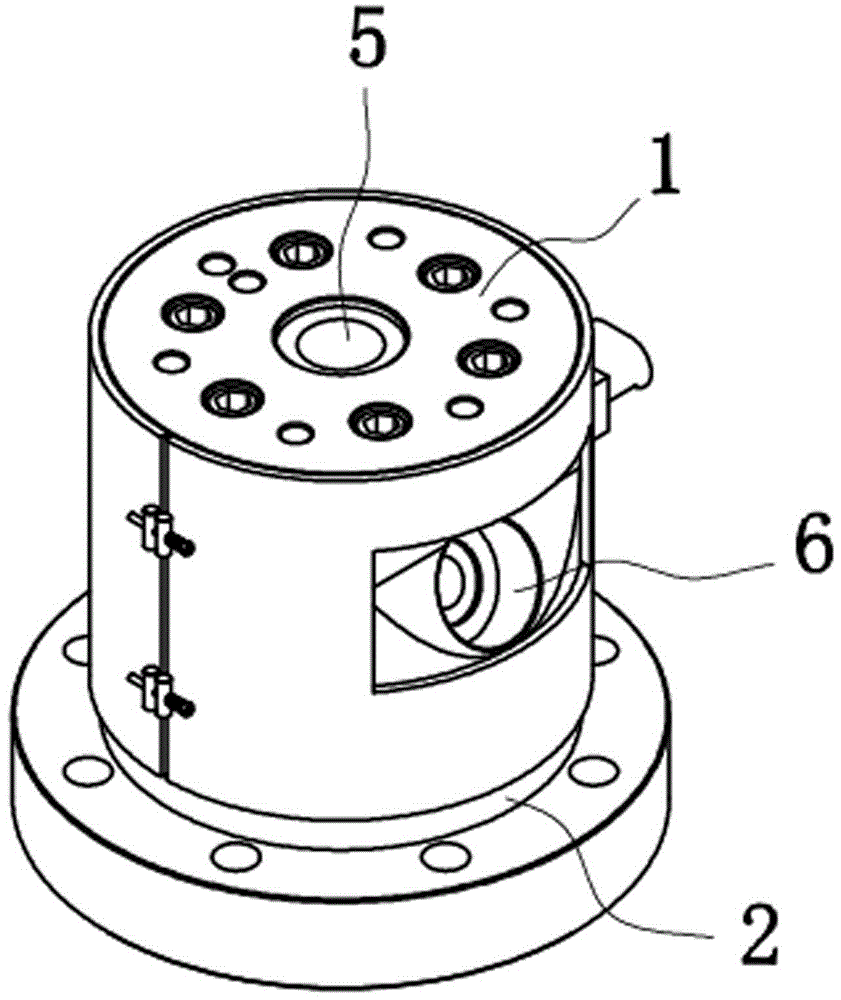

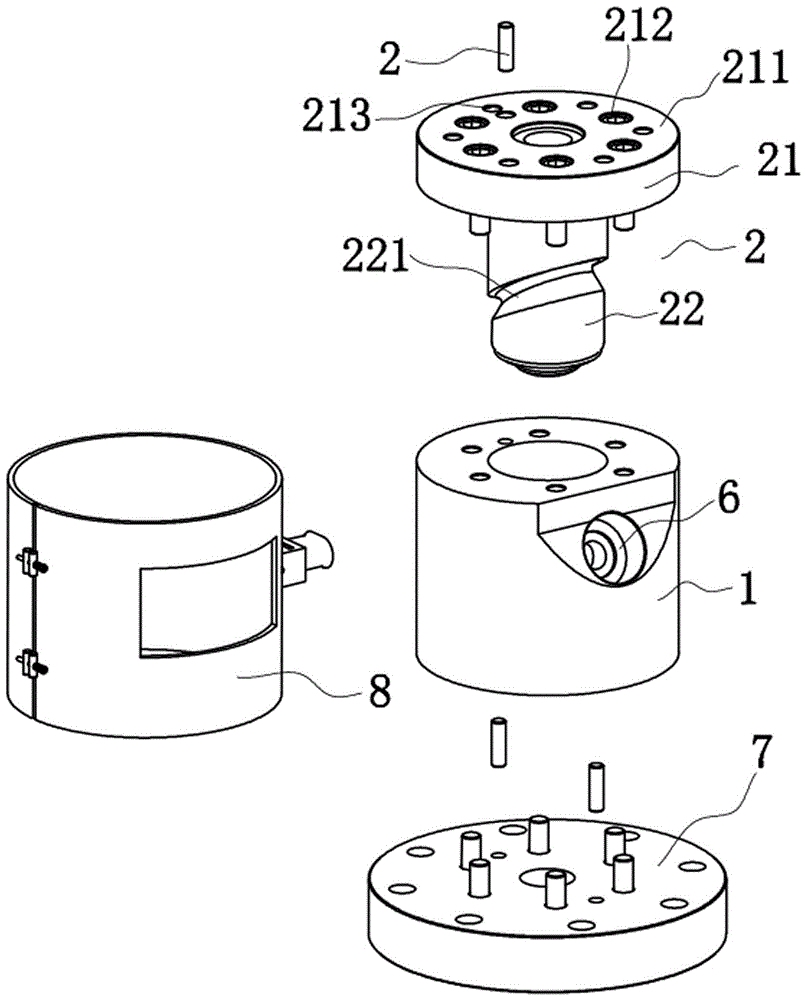

[0019] Such as Figure 1~5 As shown, the circular outlet distributor includes a main body 1 and a shunt mandrel 2, the shunt mandrel 2 is built in the main body 2, one end of the shunt mandrel 2 is a fixed end 21, and the fixed end 21 has a fixed protrusion The edge 211 and the fixing hole 212, the fixed end 21 of the shunt mandrel is matched with the end face of the main body 1 through the positioning pin 3 and the positioning hole 213, and the shunt mandrel 2 and the main body 1 are positioned and then installed into the fixing hole 212 with fixing screws Fasten the two connections.

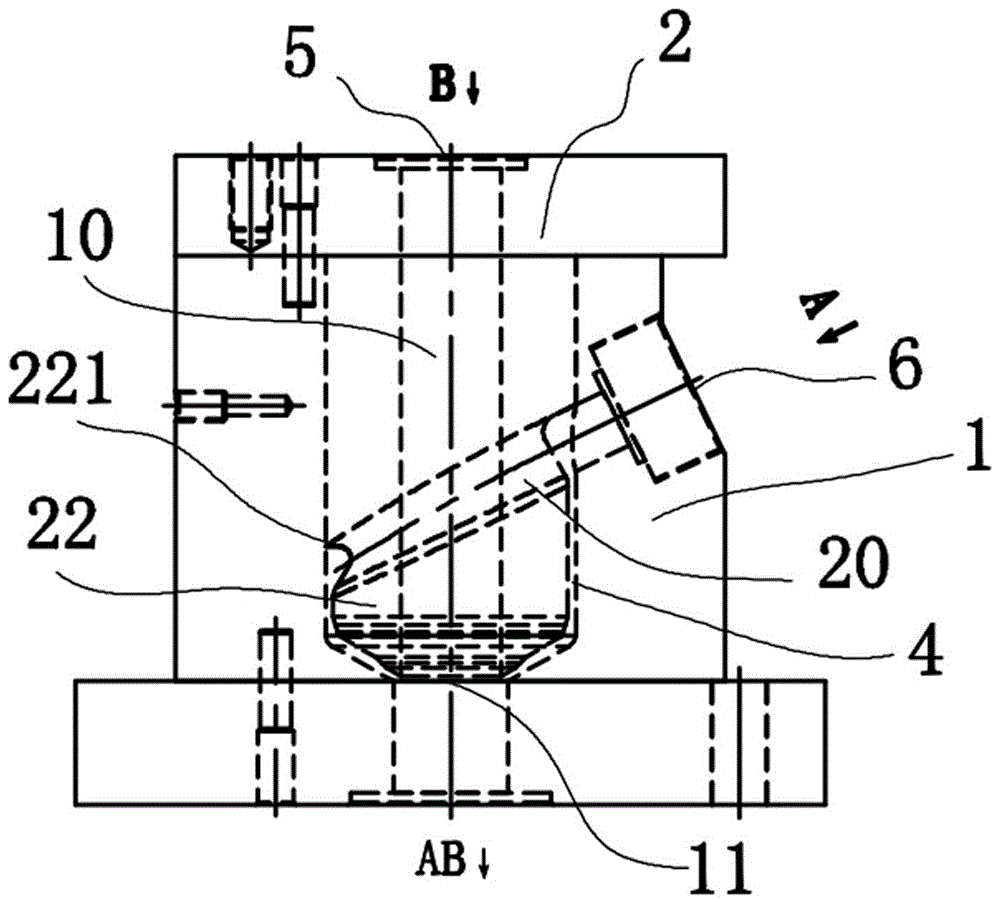

[0020] Such as figure 2 , 3 As shown, the other end of the splitter mandrel 2 is a cylindrical rod body 22, the front end of the cylindrical rod body 22 is conical. , the auxiliary machine runner groove 221 spirally extends downward toward the outlet. There is a certain gap 4 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com