An anti-climbing energy-absorbing device

An energy-absorbing device and anti-climbing technology, applied in transportation and packaging, railway car body parts, railway vehicle wheel guards/buffers, etc., can solve the problems of inability to bear vertical loads, poor energy absorption effect, and small energy absorption capacity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

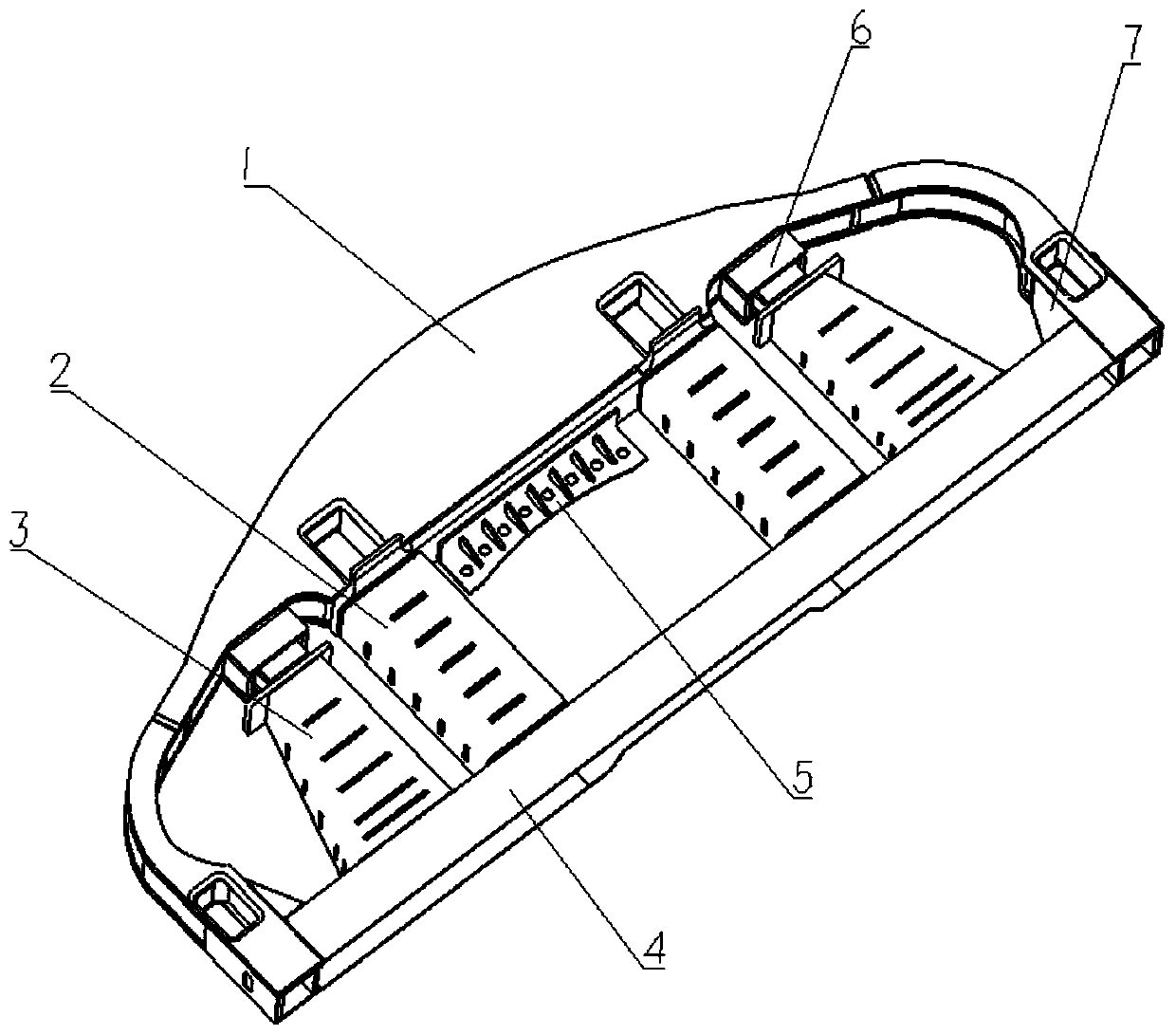

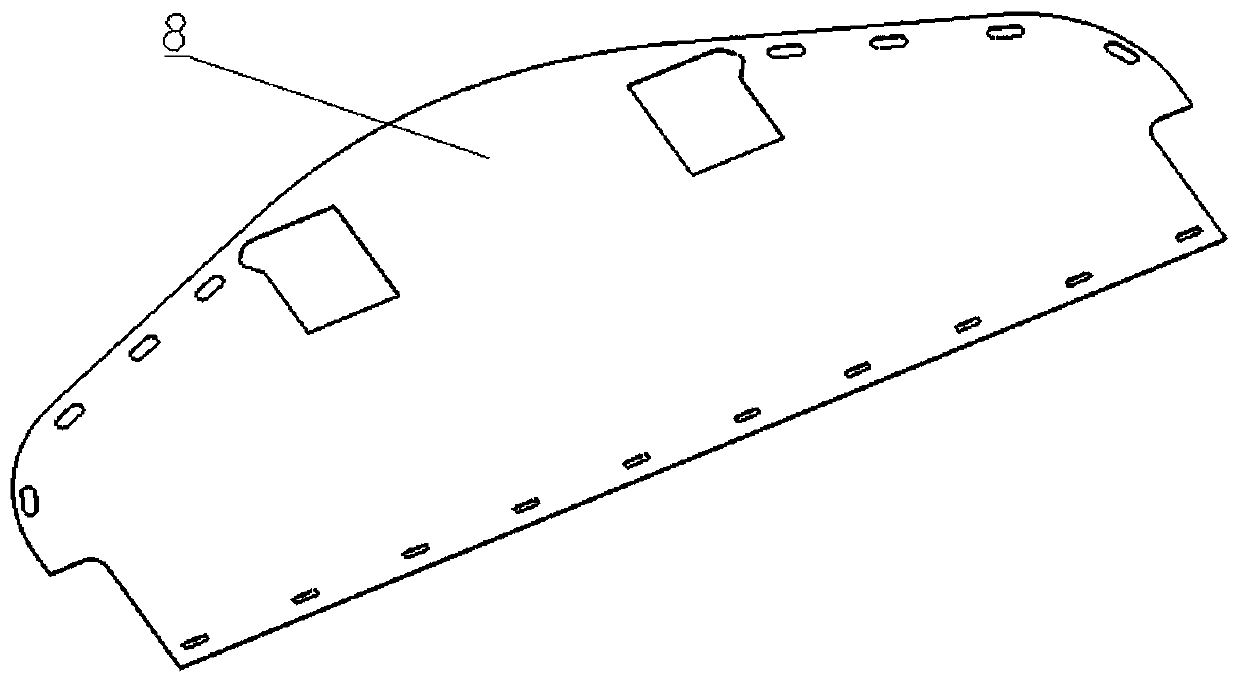

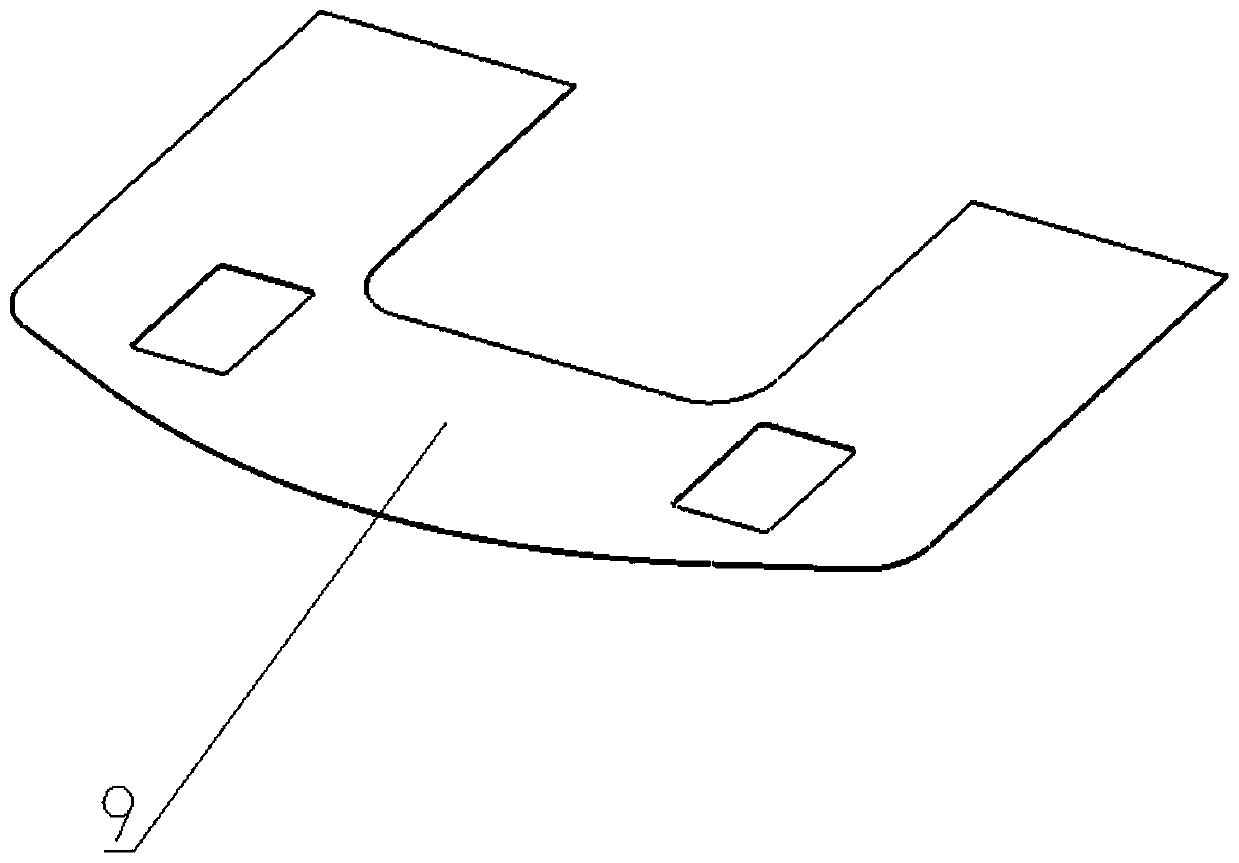

[0035] refer to figure 1 The specific embodiment of the present invention includes an anti-climber module 1, an intermediate composite structure energy-absorbing unit module 2, an energy-absorbing unit module 3 on both sides, an end beam module 4, a coupler installation support seat 5, a pin connection module 6, and an oblique support beam 7 , the upper cover plate 8, the lower cover plate 9; the anti-climber module 1 and the end beam module 4 are welded together to form a closed frame, and are fixed by the inclined support beam 7 at the same time; the energy-absorbing unit module of the intermediate composite structure 2. One end is fixed on the anti-climber module 1, and the other end is fixed on the end beam module 4; one end of the energy-absorbing unit module 3 on both sides is fixed with the anti-climber module 1 through the pin connection module 6, and the other end is fixed on the end beam module 4. On the beam module 4; the upper cover plate 8 and the lower cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com