A rotary self-locking aerosol actuator

A technology for actuators and aerosols, which can be used in spraying devices, liquid distribution, and individual handheld devices. It can solve problems such as troubles, poor hand feeling, and mispressing, and achieve convenient use, enhanced locking effect, and improved safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

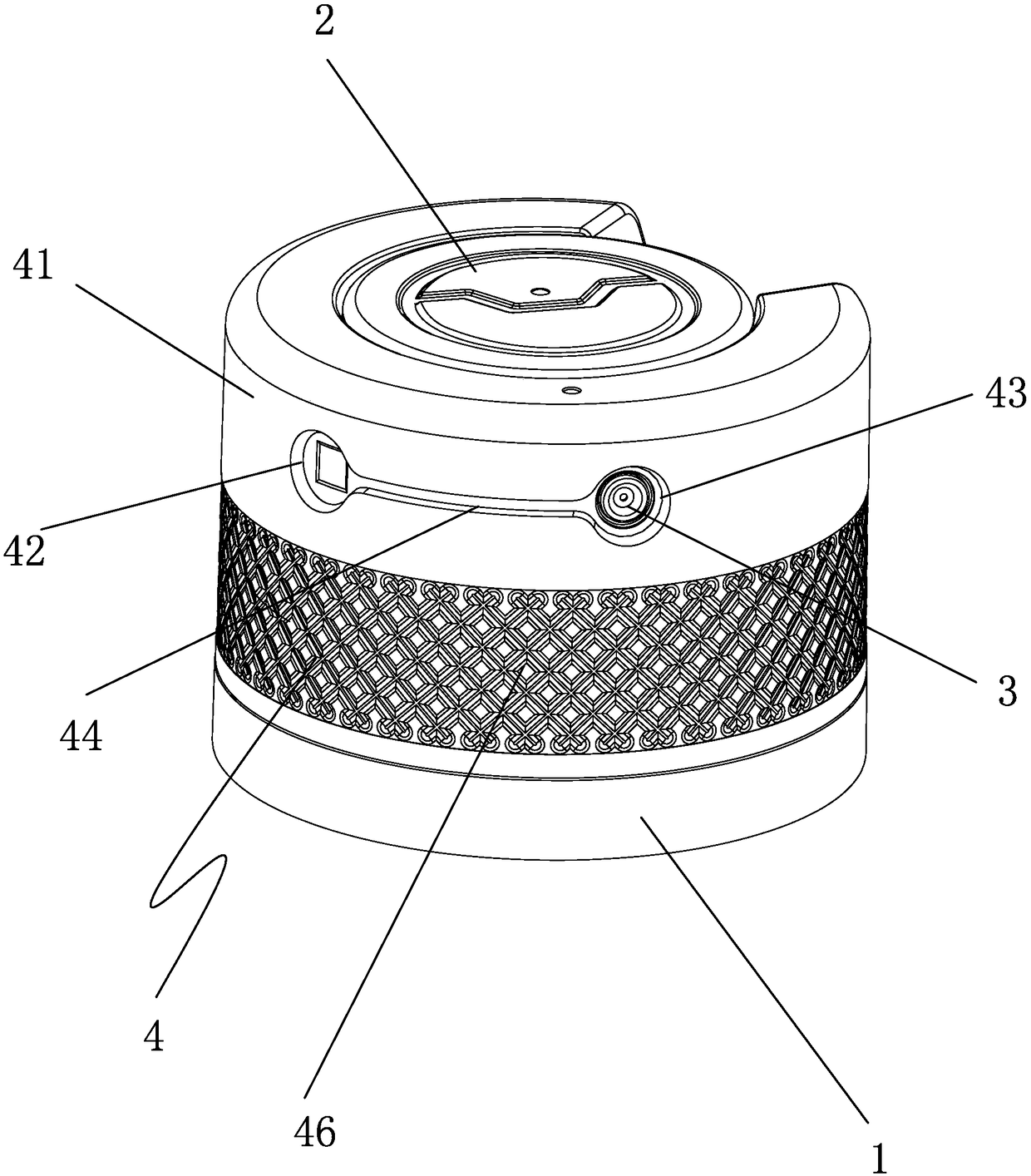

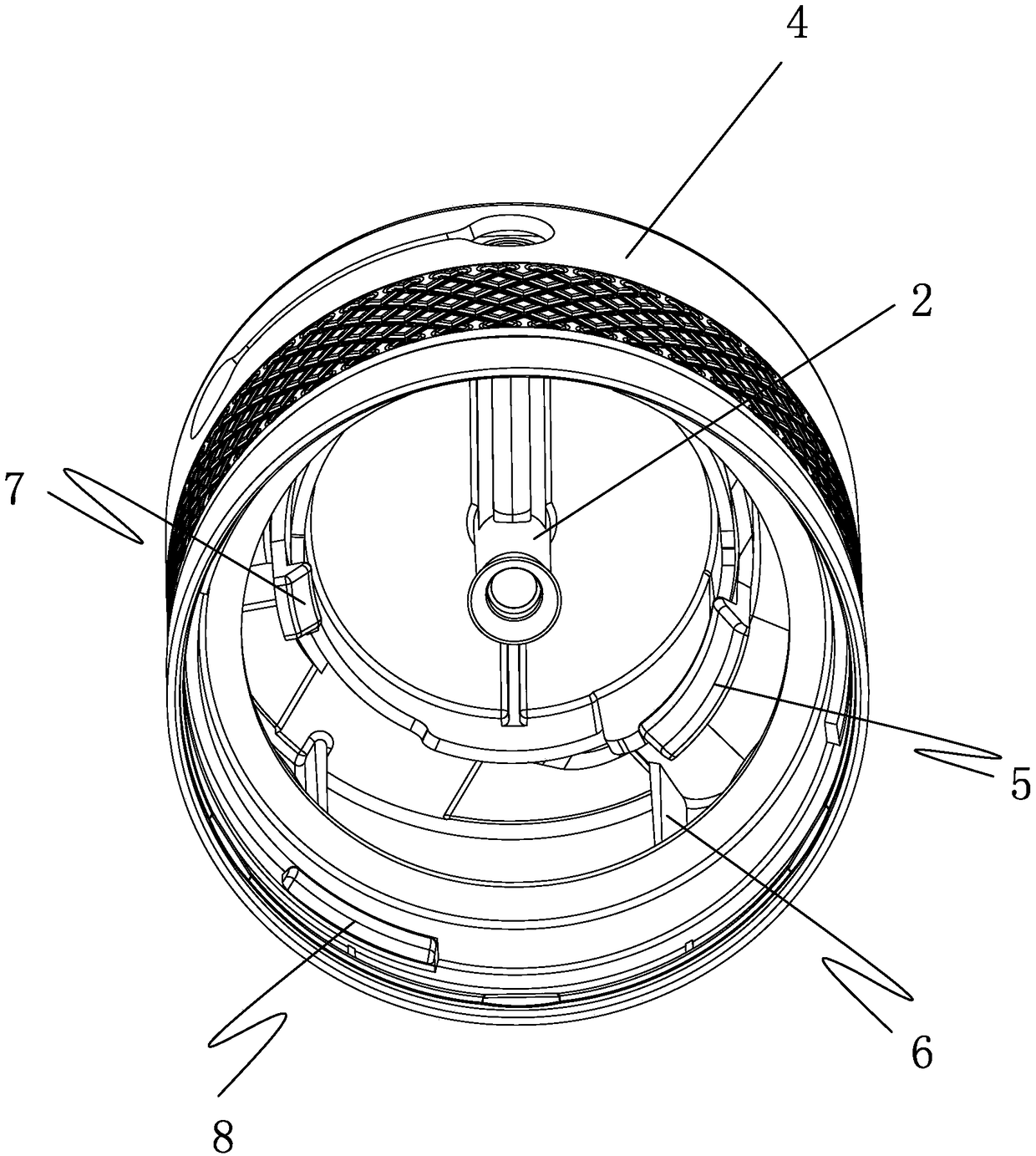

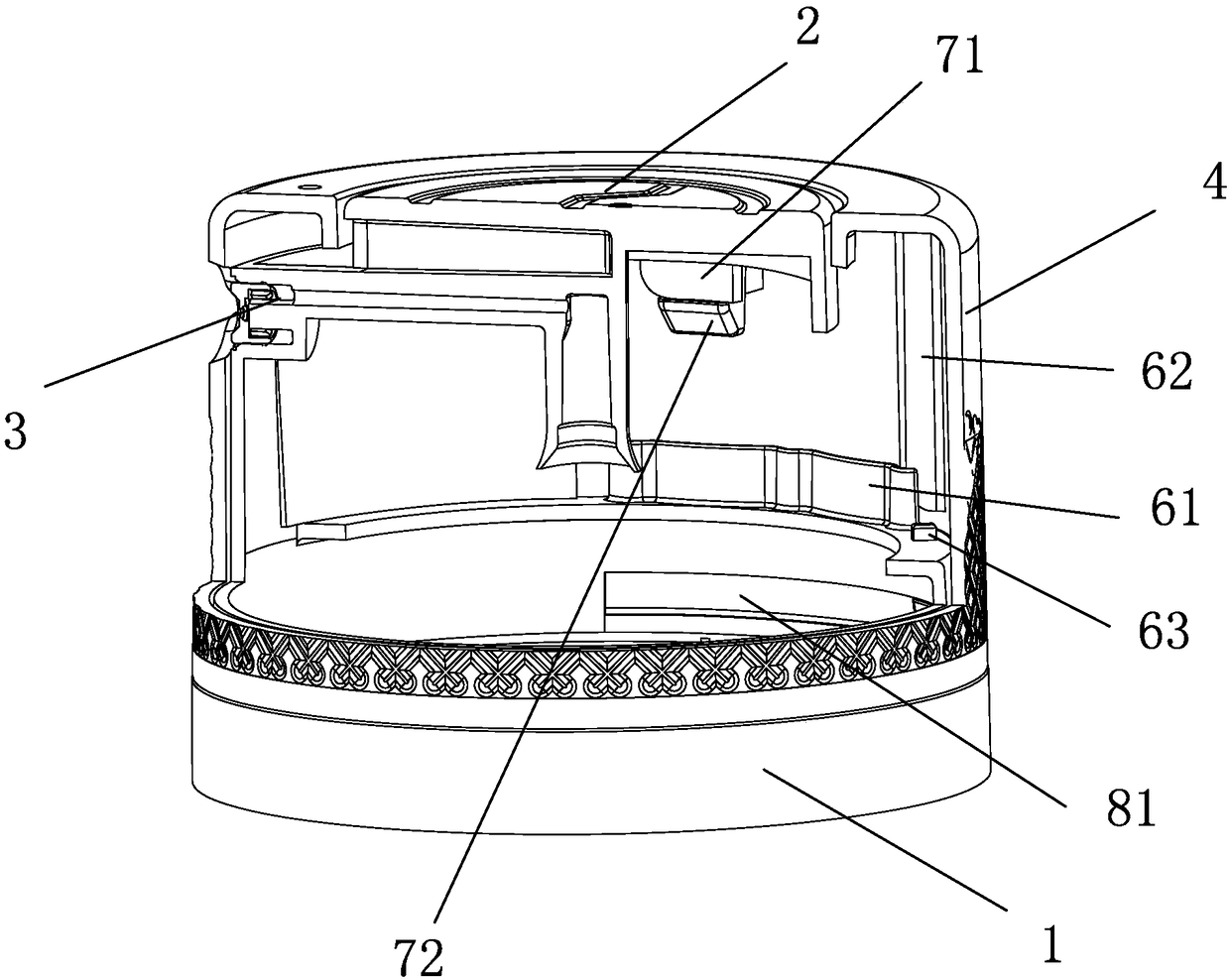

[0030] like Figures 1 to 7 A rotary self-locking aerosol actuator shown includes an actuator body 1, on which a push head 2 is arranged, and a nozzle is arranged on the push head 2 3. A rotary cover 4 that can rotate relative to the actuator main body 1 is provided outside the actuator main body 1, and a push button that can prevent the press head 2 from pressing down and moving is provided between the rotary cover 4 and the push head 2. The head locking mechanism 5 is provided with a damping device 6 between the rotating cover 4 and the pressing head 2 to enhance the rotating feel of the rotating cover 4 . In the present invention, the damping device 6 can increase the friction between the rotating cover 4 and the actuator body 1 when rotating, so that the user can obtain a good rotating feel. In addition, the pressing head locking mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com