A kind of preparation method and application of PD ion imprinted silica gel adsorbent

An ion-imprinted silica gel and adsorbent technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of non-environmental grafting efficiency and time-consuming, and achieve high mechanical stability and mechanical strength. High, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

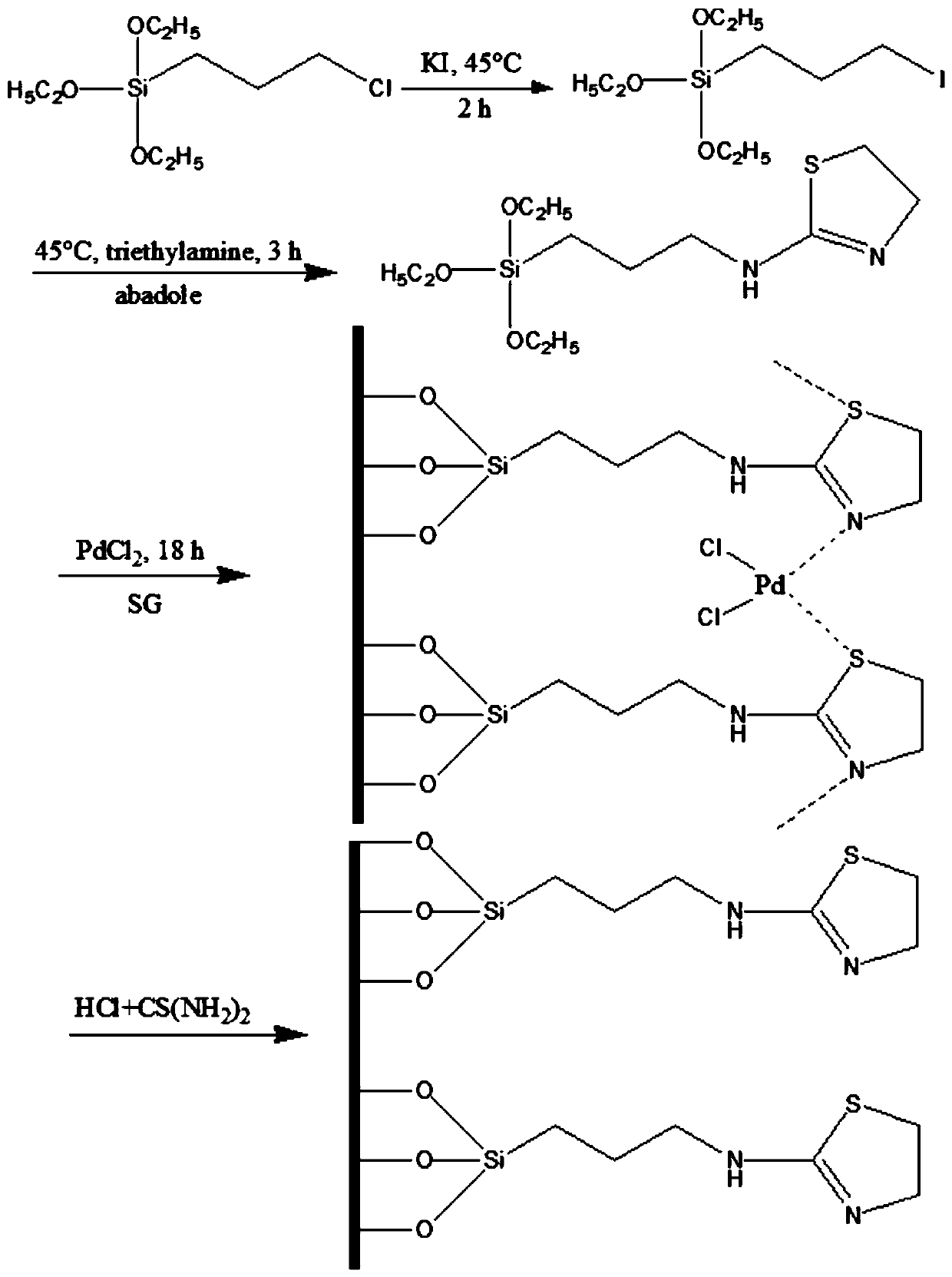

[0027] A preparation method for Pd ion imprinted silica gel adsorbent, comprising the following steps:

[0028] 1) Disperse Pd(II) salt and acid-activated silica gel (SG) in alcohol solvent;

[0029] 2) After reacting chlorosilane with KI, add 2-aminothiazole (abadole) to react under alkaline conditions;

[0030] 3) Step 1) is mixed with the product obtained in step 2);

[0031] 4) The product of step 3) is filtered and washed, and the washed product is extracted and then washed until neutral, and dried to obtain a Pd(II) ion-imprinted silica gel adsorbent.

[0032] Preferably, in step 1), the mass ratio of the Pd(II) salt to the acid-activated silica gel is 1:(6-7).

[0033] Preferably, the Pd(II) salt is PdCl 2 or Pd(NO 3 ) 2 ; Further preferably, the Pd (II) salt is PdCl 2 .

[0034] Preferably, the acid is hydrochloric acid or nitric acid; more preferably, the acid is hydrochloric acid.

[0035] Preferably, in step 1), the alcohol is one of methanol, ethanol, propa...

Embodiment

[0048] 1. Preparation

[0049] 1. Add 10g of silica gel (SG) into 100mL of concentrated HCl, heat to reflux for 6h under stirring, wash with deionized water until neutral, and dry at 180°C for 16h.

[0050] 2. Add 8mL of 3-chloropropyltriethoxysilane (CPTS) to 8g of KI, stir and react at 45°C for 2h, after fully reacting, add 6.5g of 2-aminothiazole (abadole), 0.5mL Ethylamine was stirred at 45°C for 3h.

[0051] 3. Add 1.2g PdCl 2 and 8g of SG were added to 100mL 95% ethanol solution, ultrasonicated until the mixture was uniformly dispersed, then added to the mixed solution in the previous step, heated to reflux for 18h, and filtered;

[0052] 4. Wash the filtered product with toluene, ethanol, diethyl ether and hot water several times in sequence. Wash the product with 200mL4%CS(NH 2 ) 2 and 2mol L- 1 Soxhlet extraction with HCl mixture for 5 h, washed away the imprinted Pd(II), and then washed with absolute ethanol and double distilled water until neutral. Vacuum-dri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap