Method for hydrogenation of cracked carbon nine fraction

A technology for cracking carbon and fractions, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of small processing capacity, poor product quality, fluctuation of process technical parameters, etc., and achieve the improvement of oil quality and good technology effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

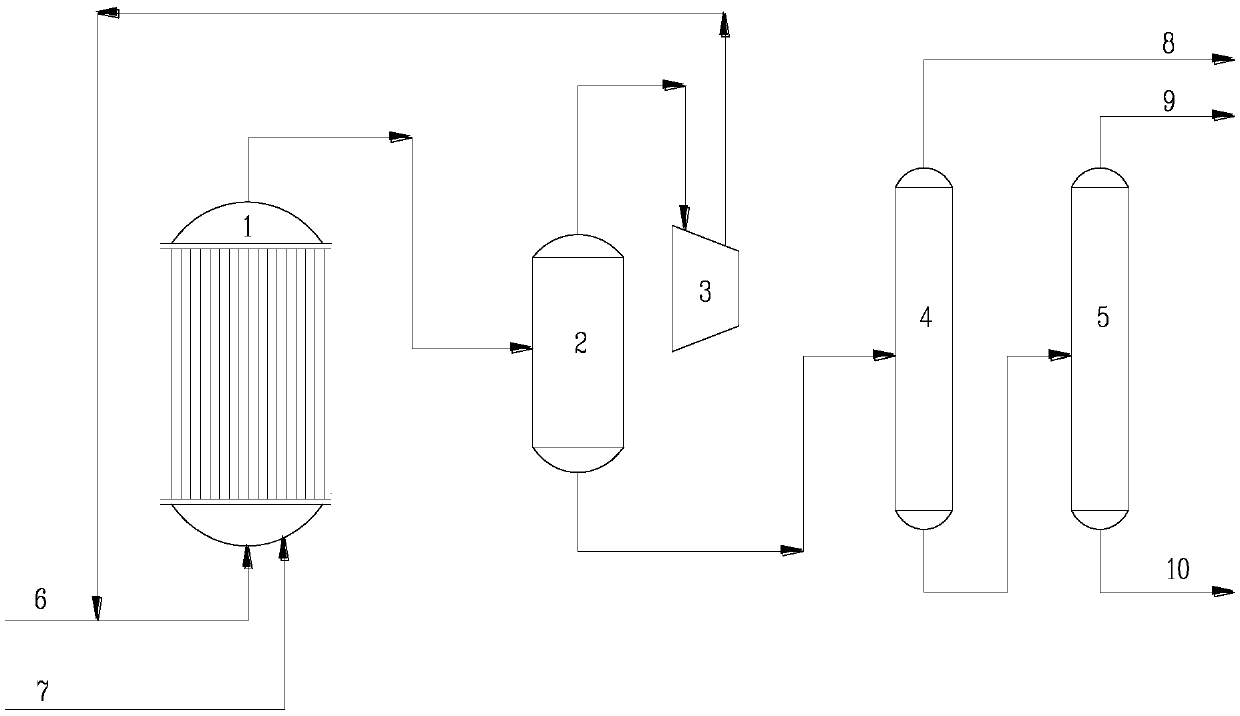

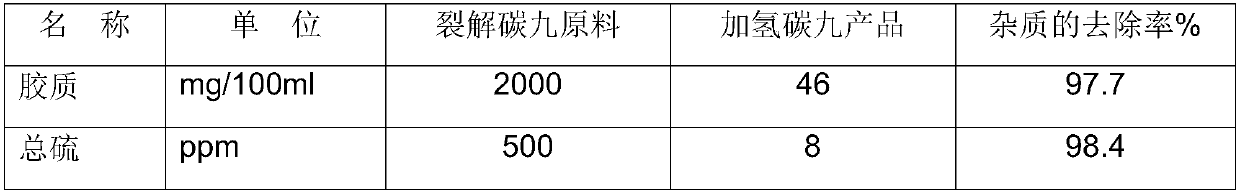

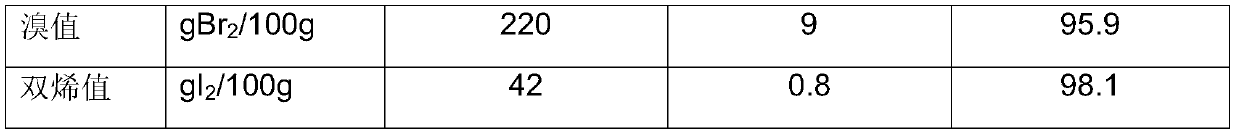

[0023] A method for hydrogenation of cracked carbon nine fractions, such as figure 1 Shown, at first, cracking carbon nine fraction raw material (7) and hydrogen raw material (6) are sent into adiabatic bed hydrogenation reactor (1) and carry out hydrogenation reaction; Then, the reaction product of hydrogenation enters gas-liquid separator (2 ), the separated gaseous material goes to the hydrogen compressor (3) pressurized and returns to recycle unreacted hydrogen; finally, the separated liquid phase material goes to the light removal tower (4), and the light removal tower top is separated The light component (8) is discharged, and the liquid phase material in the de-lightening column continues to enter the de-weighting tower (5), and the hydrogenated carbon nine product (9) is separated from the top of the de-weighting tower, and the heavy component is separated from the de-weighting tower. (10), the heavy component (10) is a hydrocarbon compound with a distillation range ≥ ...

Embodiment 2

[0029] According to the conditions and steps described in Example 1, only the production scale of the ethylene plant is changed to 1 million tons / year, and naphtha NAP is used as the cracking raw material, and the by-product cracked carbon nine fraction of the ethylene plant is about 161,000 tons / year.

[0030]Using the method for hydrogenation of the cracked C9 fraction of the present invention: first, the raw material of the cracked C9 fraction and the hydrogen raw material are sent to the adiabatic bed hydrogenation reactor for hydrogenation reaction; then, the hydrogenated reaction product enters the gas-liquid separator, and is separated The gaseous material is decompressed by the hydrogen compressor and returned to recover unreacted hydrogen and recycled; finally, the separated liquid material is sent to the light removal tower, and the light component is separated from the top of the light removal tower, and the light removal tower The liquid phase material in the kettle...

Embodiment 3

[0035] According to the conditions and steps described in Example 1, only the production scale of the ethylene unit is changed to 1.5 million tons / year, hydrogenated tail oil HVGO is used as the cracking raw material, and the by-product cracked carbon nine fraction of the ethylene unit is about 329,000 tons / year .

[0036] Adopt the method for hydrogenation of cracked carbon nine cuts of the present invention, technological operation parameter is as follows: the reaction gauge pressure of isothermal fixed-bed hydrogenation reactor 2.3MPa, reaction temperature 87 ℃, liquid space velocity 4.8h -1 , hydrogen / oil volume ratio 520:1; catalyst composition: the main active component is nickel Ni, the content is 36%, the auxiliary active component is titanium Ti, the content is 1.4%, the carrier is alumina Al 2 o 3 , the specific surface area is 310m 2 / g, the specific pore volume is 0.9ml / g. The inlet gauge pressure of the hydrogen compressor is 2.1MPa, the outlet gauge pressure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com