Method for preparing low-sulfur barium carbonate and prepared barium carbonate product

A barium carbonate and product technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of high total sulfur content, achieve the effect of reducing total sulfur and preventing the production of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

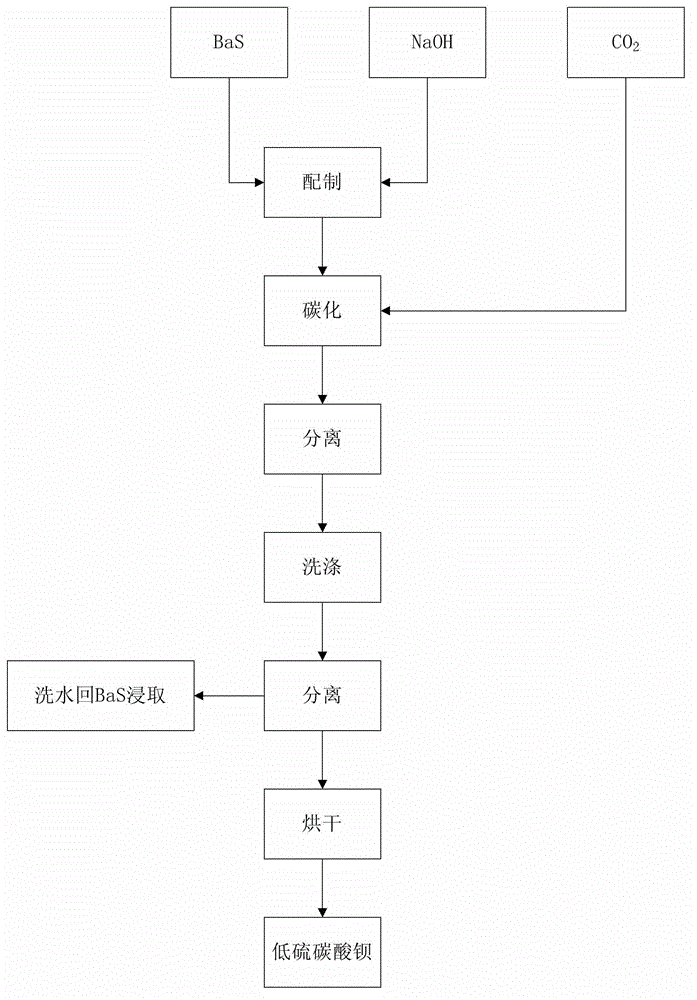

Image

Examples

Embodiment 1

[0034] Add NaOH to 120g / L BaS solution to make [Na + ] at about 0.01mol / L, control the temperature of the mixed solution to 70°C.

[0035] Put the above solution in a conventional three-tower carbonization tower, pass through lime kiln kiln gas for conventional carbonization, control the BaS concentration at the end of carbonization to 0.35g / L, and the pH value at the end point is 7.5, stop carbonization, centrifugal separation, and the filter cake enters the next step.

[0036] The above-mentioned filter cake was hot-washed twice at 1:4 ratio of material to water at 60°C for 1.5 hours, flash-dried to obtain low-sulfur barium carbonate sample 1 # .

Embodiment 2

[0038] Add NaCl in 120g / L BaS solution, make [Na + ] at about 0.02mol / L, control the temperature of the mixed solution to 80°C.

[0039] Put the above solution in a conventional three-tower carbonization tower, pass through lime kiln kiln gas for conventional carbonization, control the BaS concentration at the end of carbonization to 0.4g / L, and the pH value at the end point is 8.0, stop carbonization, centrifuge, and the filter cake enters the next step.

[0040] The above-mentioned filter cake was hot-washed twice at 1:4 ratio of material to water at 70°C for 1.5 hours, flash-dried to obtain low-sulfur barium carbonate sample 2 # .

Embodiment 3

[0042] Add KOH in 150g / L BaS solution, make [K + ] at about 0.015mol / L, control the temperature of the mixed solution to 65°C.

[0043] Put the above solution in a conventional three-tower carbonization tower, pass through lime kiln kiln gas for conventional carbonization, control the BaS concentration at the end of carbonization to 0.25g / L, and the pH value at the end point is 7.5, stop carbonization, centrifugal separation, and the filter cake enters the next step.

[0044] The above-mentioned filter cake was hot-washed twice at 1:4 ratio of material to water at 70°C for 1.5 hours, flash-dried to obtain low-sulfur barium carbonate sample 3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com