Method and equipment for producing automotive diesel fuel from medium temperature coal tar light oil as raw material

A coal tar and raw material oil technology, which is applied in the field of coal tar to prepare diesel oil, can solve the problems of restricting popularization and development, poor economic benefits, low economic benefits, etc., and achieve the effect of reliable operation of equipment, no discharge of three wastes, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

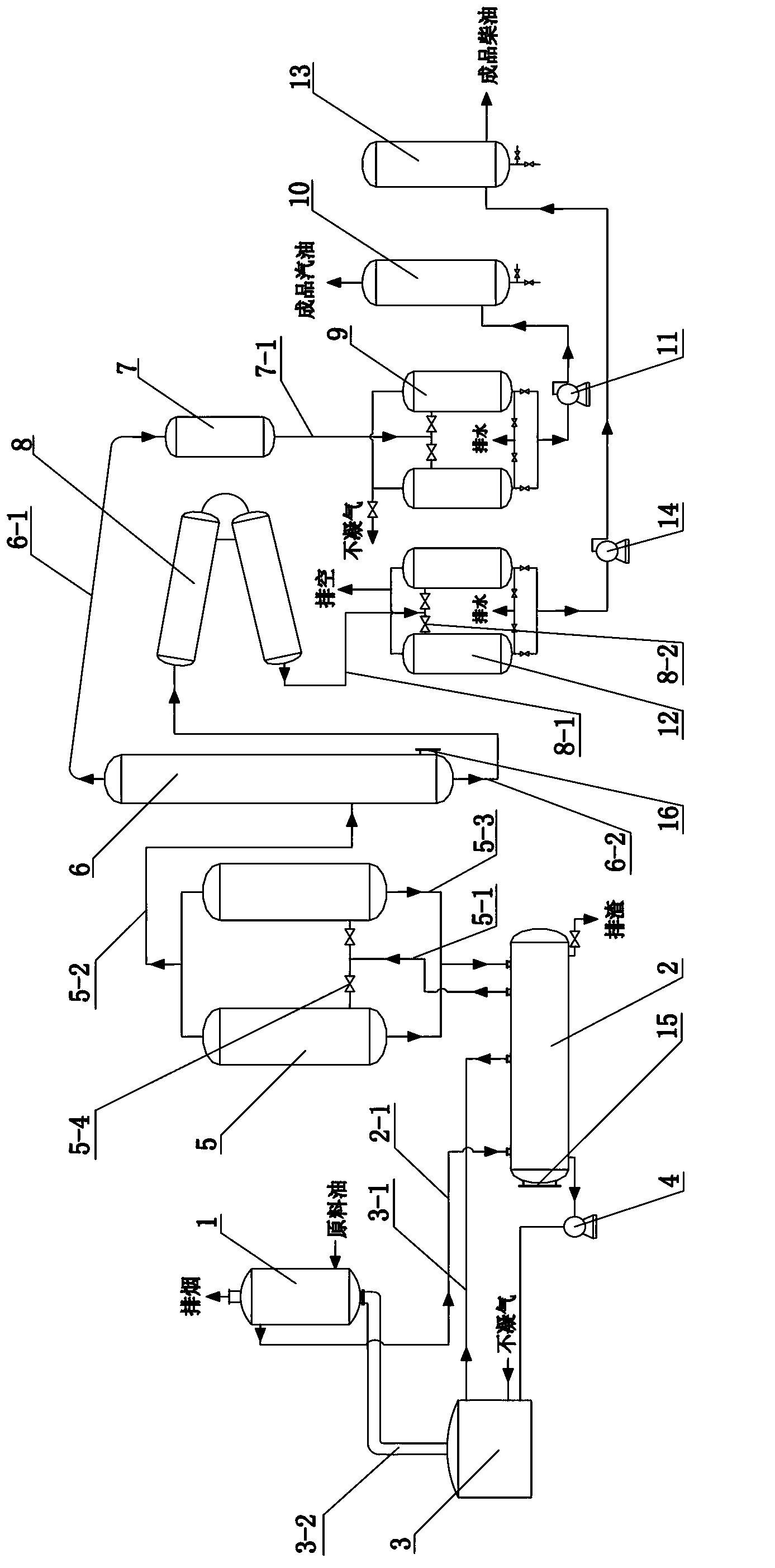

[0048] Such as figure 1 Shown is a kind of equipment for producing vehicle diesel oil with medium temperature coal tar light oil as raw material, the equipment includes a preheating tank 1 for preheating the raw material oil, and a Circulation heating system, and catalytic separation system for catalyzing and separating the raw oil after heating and gasification;

[0049] The circulating heating system includes a circulating tank 2 and a tube furnace 3 for heating and gasifying the preheated raw oil. Above the circulating tank 2 is a device that communicates with the preheating tank 1 and is used for heating the preheating tank 1. The heated raw material oil is sent to the first feed pipe 2-1 in the circulating kettle 2, and a device for pumping the raw material oil in the circulating kettle 2 into the tubular furnace 3 is arranged between the circulating kettle 2 and the tube furnace 3. The first oil pump 4 for heating and gasification, one side of the tube furnace 3 is prov...

Embodiment 2

[0057] Using the equipment of Example 1, the medium-temperature coal tar light oil—the water oil of the semi-coke factory (the main components are 20% to 25% of mixed phenol oil, 60% to 70% of high-grade aliphatic hydrocarbons, 5% to 15% of asphalt and colloid) %) is a method for producing automotive diesel as a raw material, comprising the following steps:

[0058] Step 1. Use methanol to extract and dephenolize medium-temperature coal tar light oil, and inject the medium-temperature coal tar light oil after extraction and dephenolization as raw material oil into the preheating tank 1 to preheat to 100°C; the amount of methanol used is medium-temperature coal 3 times the volume of tar light oil, the extraction temperature is 30°C;

[0059] Step 2. The preheated raw material oil enters the circulating kettle 2 (50 cubic meters) through the first feeding pipe 2-1. When the liquid level in the circulating kettle 2 rises to 50cm (about 6 tons of raw materials), the second An oil...

Embodiment 3

[0065] Using the equipment of Example 1, the medium-temperature coal tar light oil—the water oil of the semi-coke factory (the main components are 20% to 25% of mixed phenol oil, 60% to 70% of high-grade aliphatic hydrocarbons, 5% to 15% of asphalt and colloid) %) is a method for producing automotive diesel as a raw material, comprising the following steps:

[0066] Step 1. Use methanol to extract and dephenolize medium-temperature coal tar light oil, and inject the medium-temperature coal tar light oil after extraction and dephenolization as raw material oil into the preheating tank 1 to preheat to 260°C; the amount of methanol used is medium-temperature coal Twice the volume of tar light oil, the extraction temperature is 25°C;

[0067]Step 2. The preheated raw oil enters the circulating kettle 2 through the first feed pipe 2-1, and when the liquid level in the circulating kettle 2 rises to 100 cm, the first oil pump 4 is turned on to pump the raw oil in the circulating kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com