Entrained bed reactor for the production of synthesis gas

A synthesis gas and reactor technology, which is applied in the manufacture of combustible gas, gasification process, granular/powder fuel gasification, etc., can solve the problems of high cost and lack of protection, and achieve simplified structural structure, easy access, The effect of improving accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

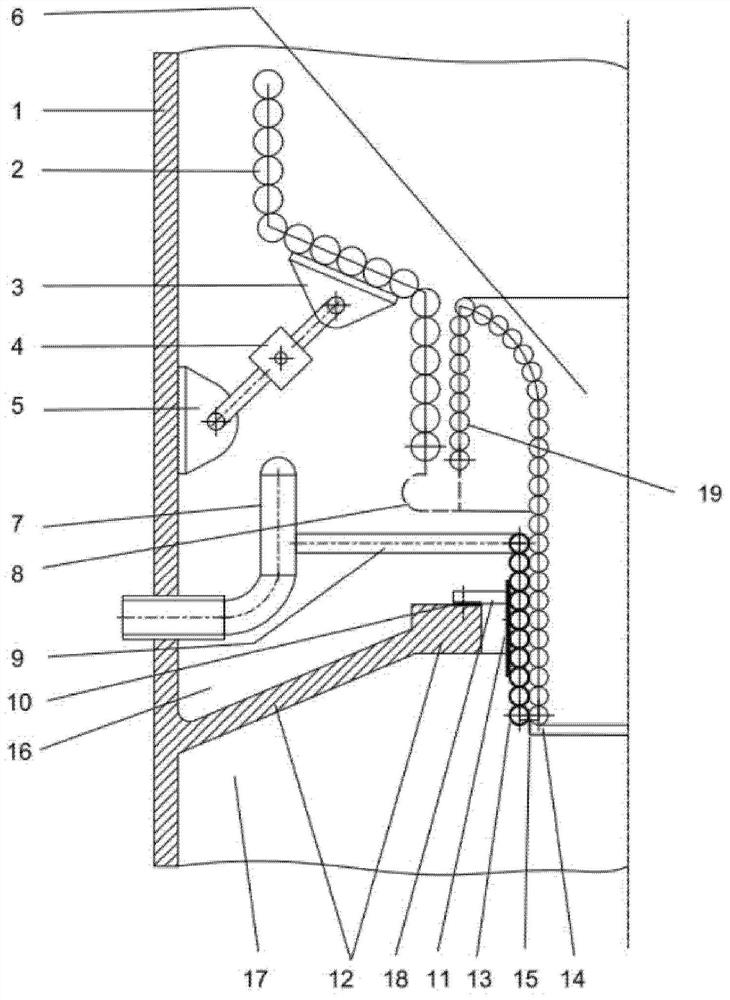

[0029]An entrained-bed reactor for the production of synthesis gas from carbonaceous fuels according to the downstream principle initially consists of an outer, pressure-containing jacket (reactor wall 1 ). Arranged in the upper part of the reactor is a reaction chamber in which crude gases and residues form at high temperature and high pressure. To protect the pressurized reactor wall 1, the reaction chamber is delimited by a cylindrical cooling screen 2, which has a conical lower section and consists of coils through which cooling water flows, which are gas-tight connected to each other.

[0030] Between the reactor wall 1 and the cooling screen 2 there is an annular space 16 which can be purged with an inert gas which can be introduced from the outside in order to protect the reactor wall 1 and the cooling screen 2 from being caused by Corrosion caused by stray reactive gases.

[0031] A quenching space 17 adjoins the reaction chamber in the direction of flow of the raw g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com