Soft soil foundation pit construction method by using dynamic compaction block stone displacement instead of supporting

A construction method and technology of tamping blocks, which are applied in the fields of infrastructure engineering, excavation, soil protection, etc., can solve the problems of material waste, polluting the environment, construction period, and high construction cost, so as to achieve simple construction steps, avoid waiting for strength growth, and improve engineering quality. The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] The implementation of the present invention will be described in detail below in conjunction with specific embodiments.

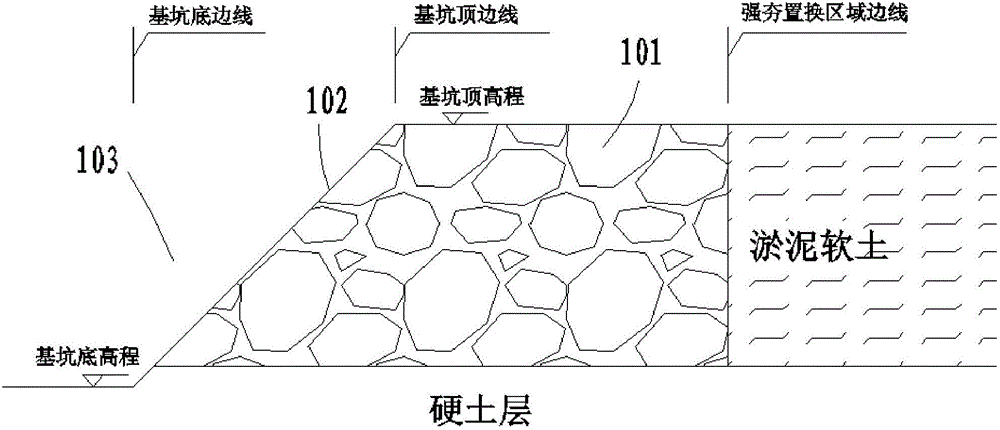

[0030] refer to figure 1 Shown is the preferred embodiment provided by the present invention.

[0031] The soft soil foundation pit construction method provided by this embodiment is used for excavating the foundation pit 103 in the silt soft soil area, and the construction method includes the following steps:

[0032] 1) According to the design requirements, set-out positioning along a certain width range outside the bottom edge of the foundation pit to be excavated, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap