Device for connecting shear wall and concrete floor in building structure and setting method of device

A technology for building structures and shear walls, applied in building structures, buildings, etc., can solve the problems of large workload, reduced bearing capacity, low concrete strength, etc., and achieves less welding workload, less manual workload, and time-consuming less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

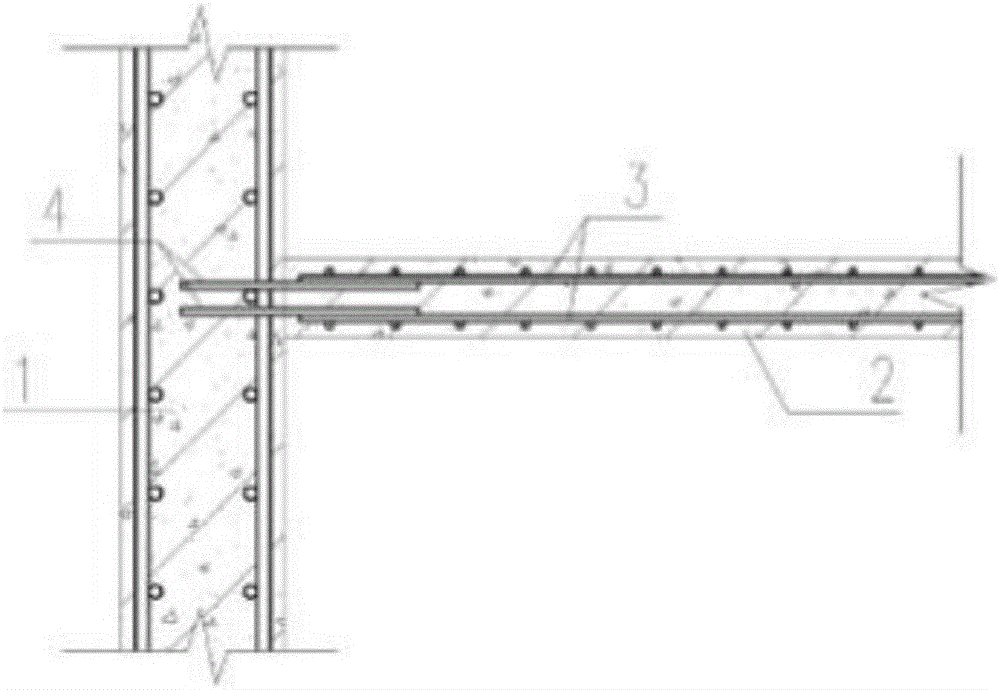

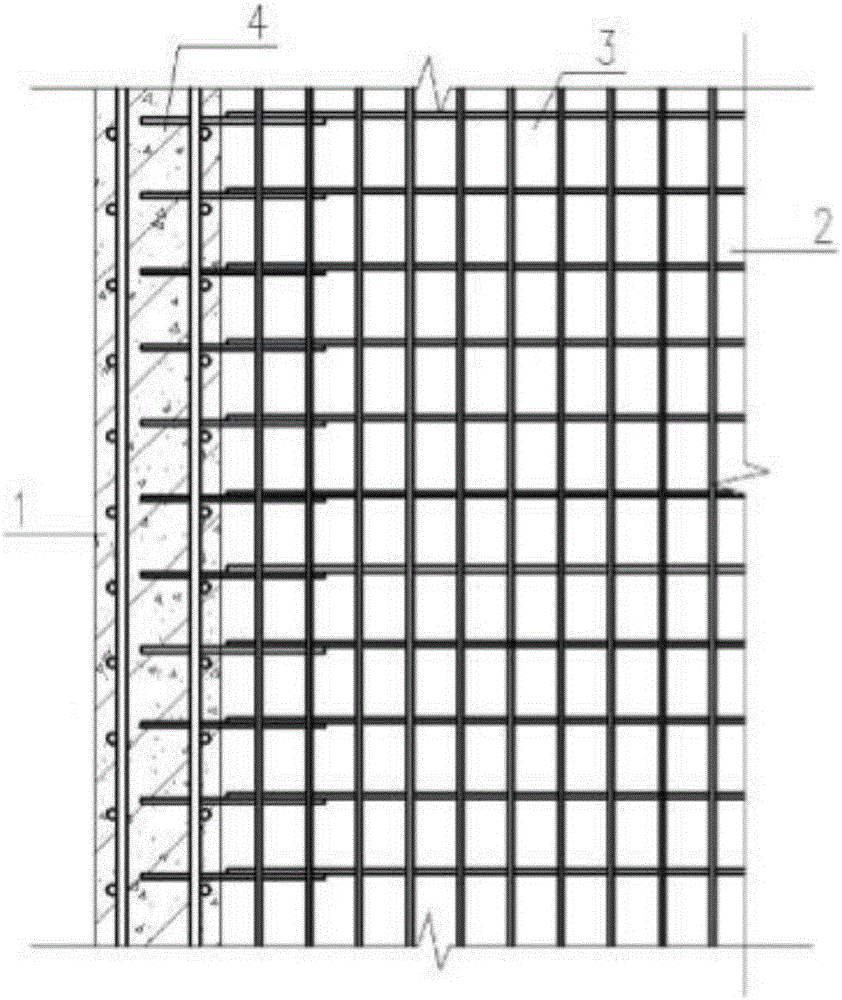

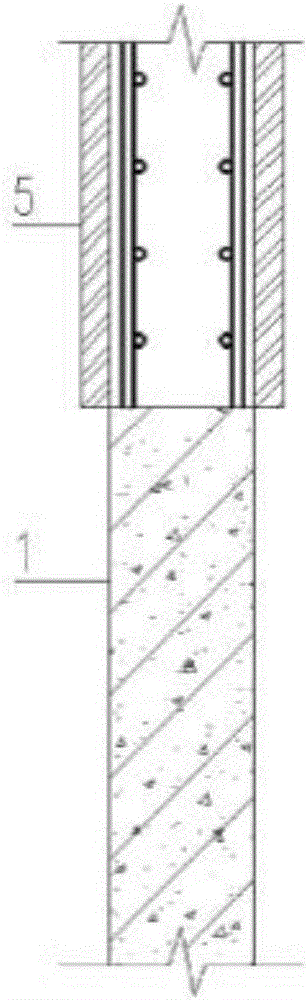

[0059] The structural design of a high-rise building has a total of 60 floors and a total height of more than 250 meters. The frame-core tube structure system is adopted, that is, the core tube is composed of 4 closed shear walls 1 in the central area of the building, and the thickness of the shear wall 1 is selected For: the wall thickness of the 1st to 10th floors is 1000mm; The thickness of the 60-layer wall is 500mm.

[0060] The length of the four shear walls 1 forming the core tube is 25m in the horizontal direction, and frame columns 9 are arranged around the core tube, as shown in Figure 8 shown. The thickness of the concrete floor 2 is 110mm, and the steel bar 3 pointing to the shear wall 1 in the slab adopts the third-grade steel bar with the design strength f2=360MPa, which is arranged on the surface and bottom of the slab. The diameter of the steel bar 3 in the slab is 10mm, and the spacing is 100mm.

[0061] According to the construction sequence, the shear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com