Corner structure of wood flour and plastic doors and windows

A door and window and wood-plastic technology, which is applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of easy deformation, high energy consumption, and easy damage, and achieve the goals of prolonging service life, firm structure of doors and windows, and guaranteed strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

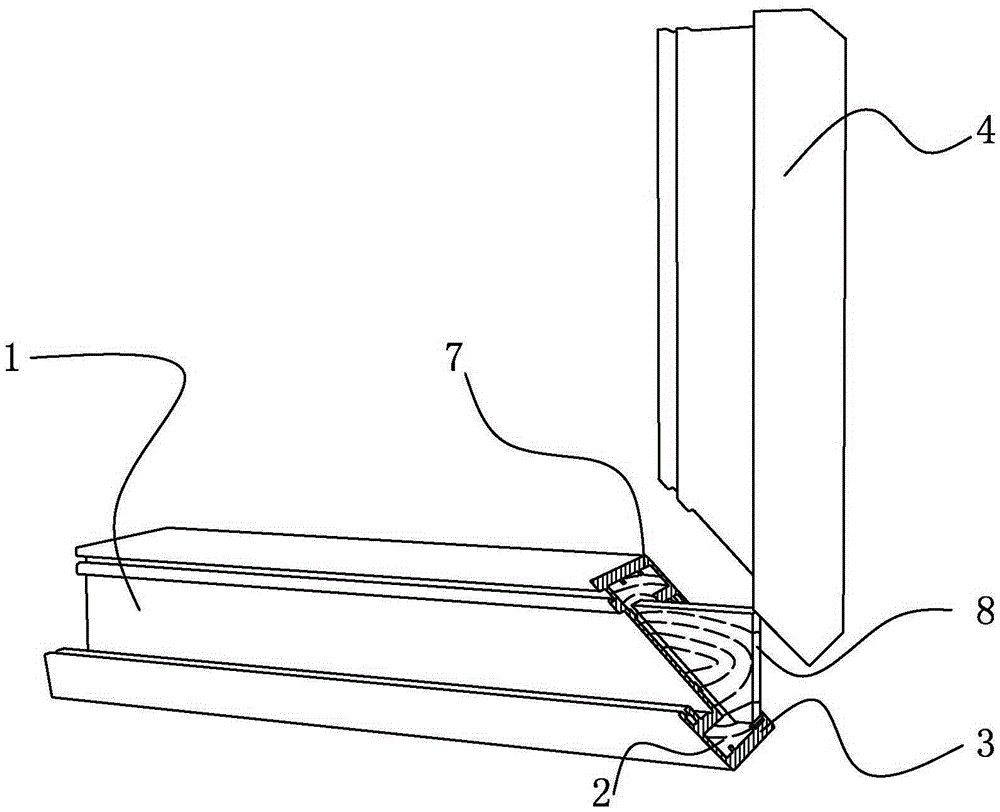

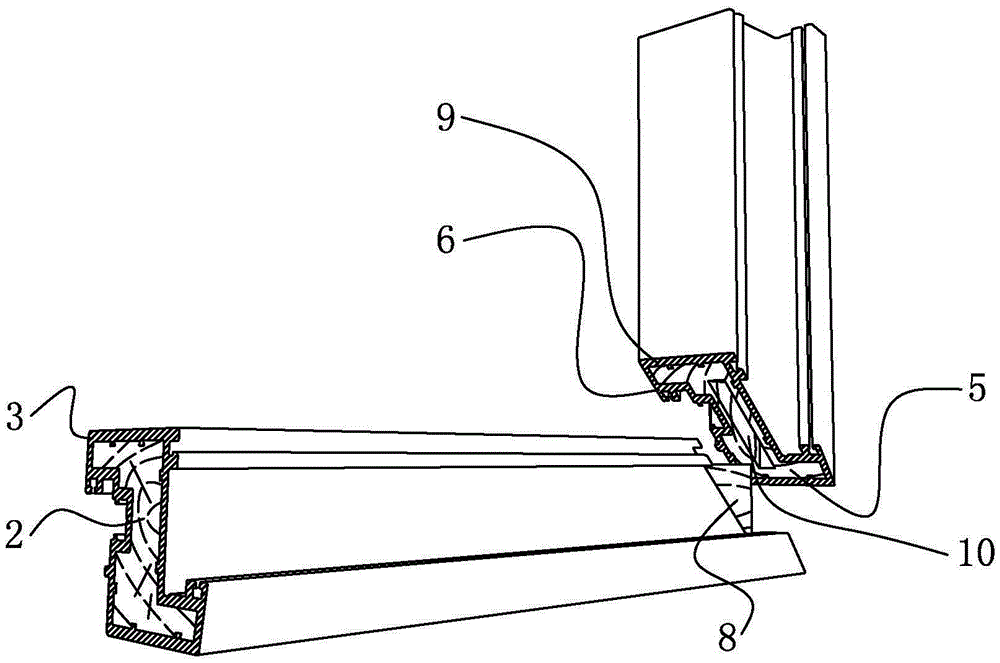

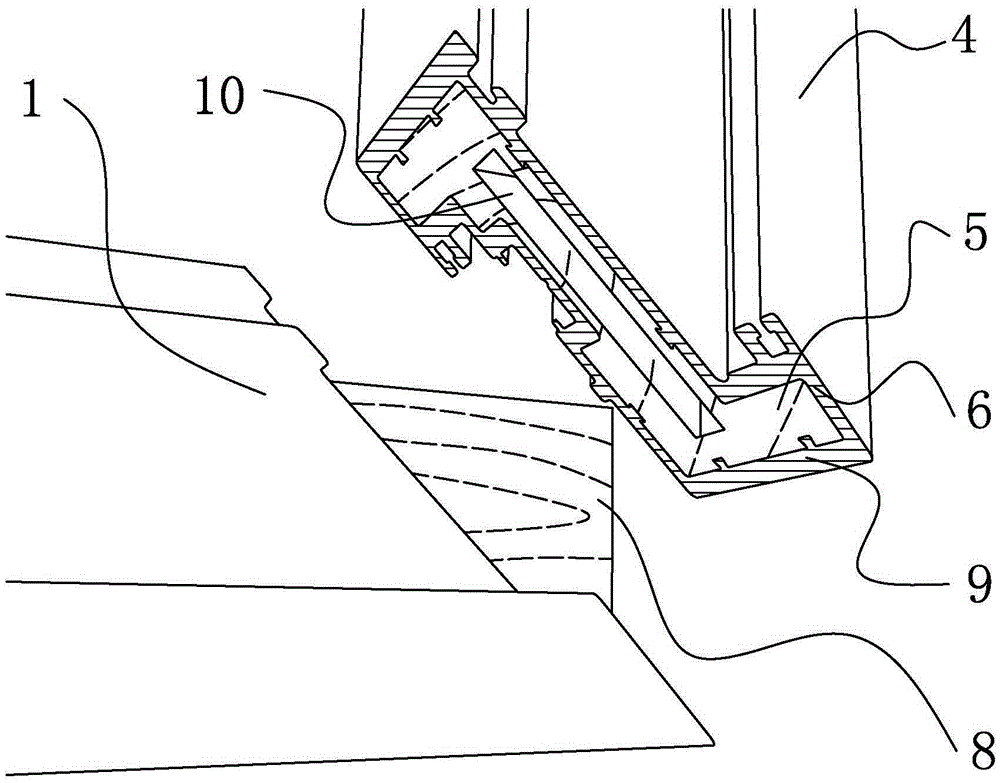

[0017] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a corner structure of a wood-plastic door and window, which has a door and window transverse profile and a door and window longitudinal profile perpendicular to it, the door and window transverse profile has a first solid wood core and a first wood-plastic cladding layer, the The door and window longitudinal profile has a second solid wood core and a second wood-plastic cladding layer, at least one end of the door and window transverse profile has a first end surface that forms an angle of 25° with the side of the door and window transverse profile, and the first end surface The first solid wood core part has a tenon-shaped protrusion consistent with the length direction of the door and window transverse profile; at least one end of the door and window longitudinal profile has a second end surface at an angle of 65° with the side of the door and window longitudinal profile, so T...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment, a corner structure of a wood-plastic door and window, which has a door and window transverse profile and a door and window longitudinal profile perpendicular to it, the door and window transverse profile has a first solid wood core and a first wood-plastic cladding layer, the The door and window longitudinal profile has a second solid wood core and a second wood-plastic cladding layer, at least one end of the door and window transverse profile has a first end surface at an angle of 45° to the side of the door and window transverse profile, and the first end surface The first solid wood core part has a tenon-shaped protrusion consistent with the length direction of the door and window transverse profile; at least one end of the door and window longitudinal profile has a second end surface at an angle of 45° with the side of the door and window longitudinal profile, so The sec...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, a corner structure of a wood-plastic door and window, which has a door and window transverse profile and a door and window longitudinal profile perpendicular to it, the door and window transverse profile has a first solid wood core and a first wood-plastic cladding layer, the The door and window longitudinal profile has a second solid wood core and a second wood-plastic cladding layer, at least one end of the door and window transverse profile has a first end surface at an angle of 60° with the side of the door and window transverse profile, and the first end surface The first solid wood core part has a tenon-shaped protrusion consistent with the length direction of the door and window transverse profile; at least one end of the door and window longitudinal profile has a second end surface at an angle of 30° with the side of the door and window longitudinal profile, so The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com