Efficient heat-preservation SMC sheet molding compound and preparation method thereof

A sheet molding compound, high-efficiency technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as insufficient thermal insulation and protection structure, inability to use car shells, high energy consumption for cooling and heating, etc. Achieve the effect of small product shrinkage, reduced thermal conductivity, and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

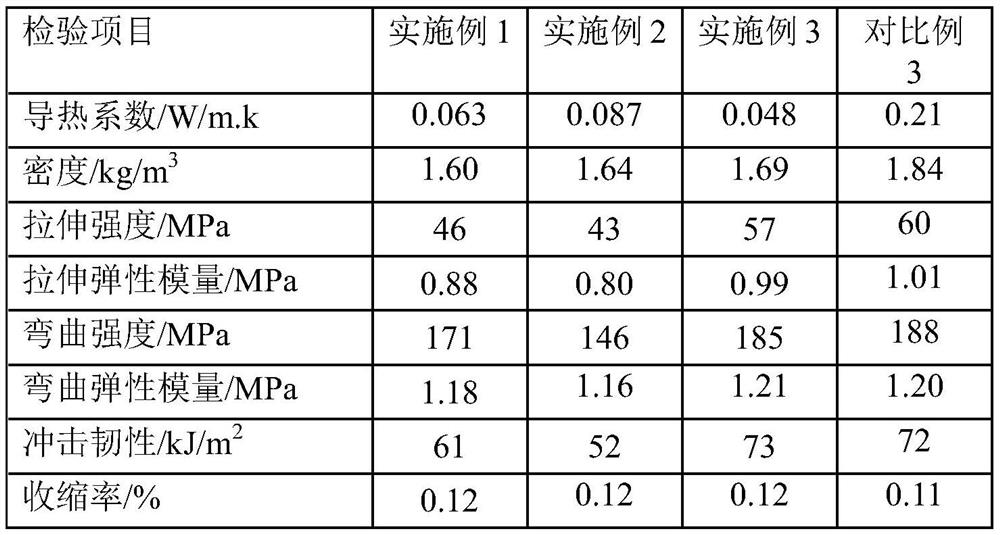

Examples

Embodiment 1

[0035] The raw material formula for the manufacture of SMC sheet molding compound is as follows:

[0036] 55kg unsaturated polyester resin (Jiangsu Fuling Chemical Co., Ltd., FL-9506), 35kg polystyrene low-shrinkage additive (Futian Chemical Industry Co., Ltd., LY-D1), 2kg zinc stearate, 0.1kg p-benzoquinone, 0.5kg part of tert-butyl peroxybenzoate, 5kg fumed silica (particle size 7-40nm), 20kg expanded perlite (particle size less than 400 mesh), 20kg hollow floating beads (particle size 2-5μm), 110kg filler (55kg calcium powder, 55kg aluminum powder), 1kg magnesia paste (25% by weight active magnesia RA-150 dissolved in carrier resin) and 50kg glass fiber (length 3mm).

[0037] The preparation method steps of this SMC sheet molding compound are as follows:

[0038] (1) Put the used powder raw material fumed silica, expanded perlite, and hollow floating beads into a drying oven, and dry at 100-180°C until the moisture content is ≤0.1%;

[0039] (2) Pour unsaturated polyester...

Embodiment 2

[0043] The raw material formula for the manufacture of SMC sheet molding compound is as follows:

[0044] 60kg unsaturated polyester resin (Jiangsu Fuling Chemical Co., Ltd., FL-9506), 38kg polystyrene low-shrinkage additive (Futian Chemical Industry Co., Ltd., LY-D1), 3kg zinc stearate, 0.3kg p-benzoquinone, 1kg part tert-butyl peroxybenzoate, 20kg fumed silica (7-40nm particle size), 20kg expanded perlite (less than 400 mesh particle size), 60kg hollow floating beads (2-5μm particle size), 150kg filler ( 60kg calcium powder, 90kg aluminum powder), 2kg magnesia paste (25% by weight active magnesia RA-150 dissolved in carrier resin) and 60kg glass fiber (length 3mm).

[0045] The preparation method steps of this SMC sheet molding compound are as follows:

[0046] (1) Put the used powder raw material fumed silica, expanded perlite, and hollow floating beads into a drying oven, and dry at 100-180°C until the moisture content is ≤0.1%;

[0047] (2) Pour unsaturated polyester re...

Embodiment 3

[0051] The raw material formula for the manufacture of SMC sheet molding compound is as follows:

[0052]65kg unsaturated polyester resin (Jiangsu Fuling Chemical Co., Ltd., FL-9506), 45kg polystyrene low shrinkage additive (Futian Chemical Industry Co., Ltd., LY-D1), 5kg zinc stearate, 0.5kg p-benzoquinone, 1.5kg portion of tert-butyl peroxybenzoate, 20kg fumed silica, 20kg expanded perlite (particle size less than 400 mesh), 20kg hollow floating beads (particle size 2-5μm), 180kg filler (90kg calcium powder, 90kg aluminum powder), 3kg of magnesia paste (25% by weight active magnesia RA-150 dissolved in carrier resin) and 80kg of glass fibers (length 6mm).

[0053] The preparation method steps of this SMC sheet molding compound are as follows:

[0054] (1) Put the used powder raw material fumed silica, expanded perlite, and hollow floating beads into a drying oven, and dry at 100-180°C until the moisture content is ≤0.1%;

[0055] (2) Pour unsaturated polyester resin and lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com