Energy-saving cantilever single winch and working method thereof

A single stranding machine and cantilever technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of heavy weight and consume more energy, and achieve the effect of reducing the difficulty of operation, realizing semi-automatic production and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

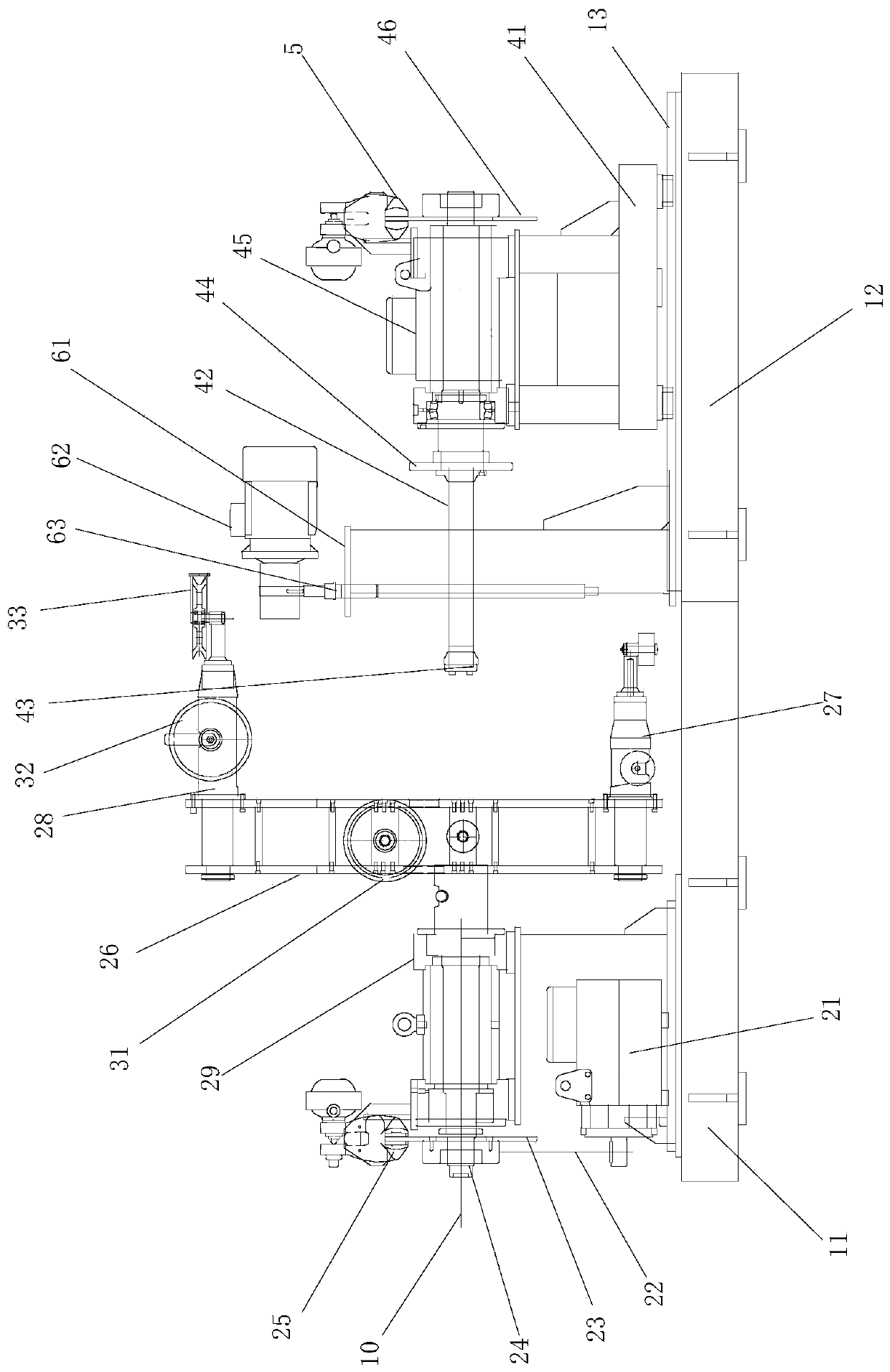

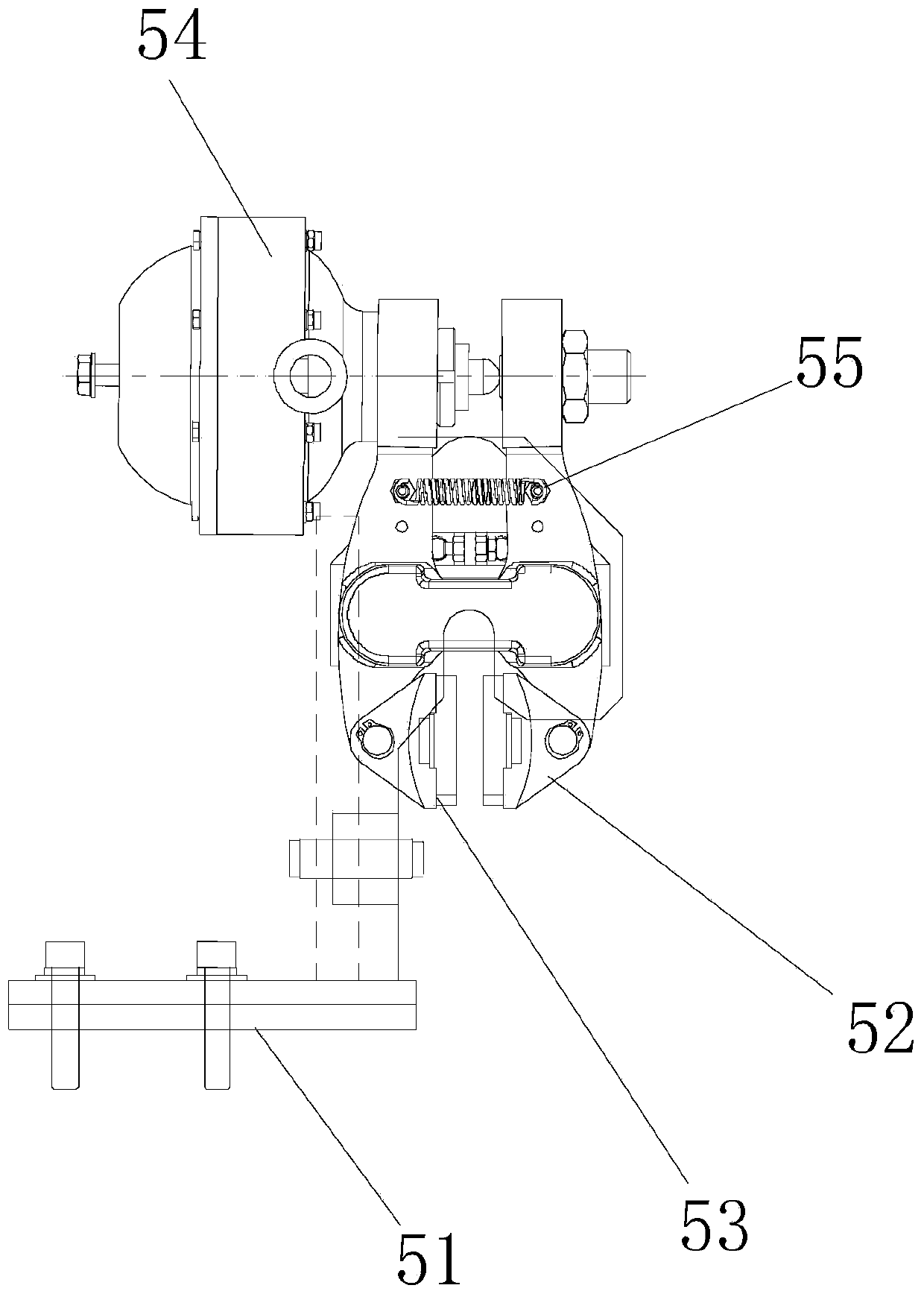

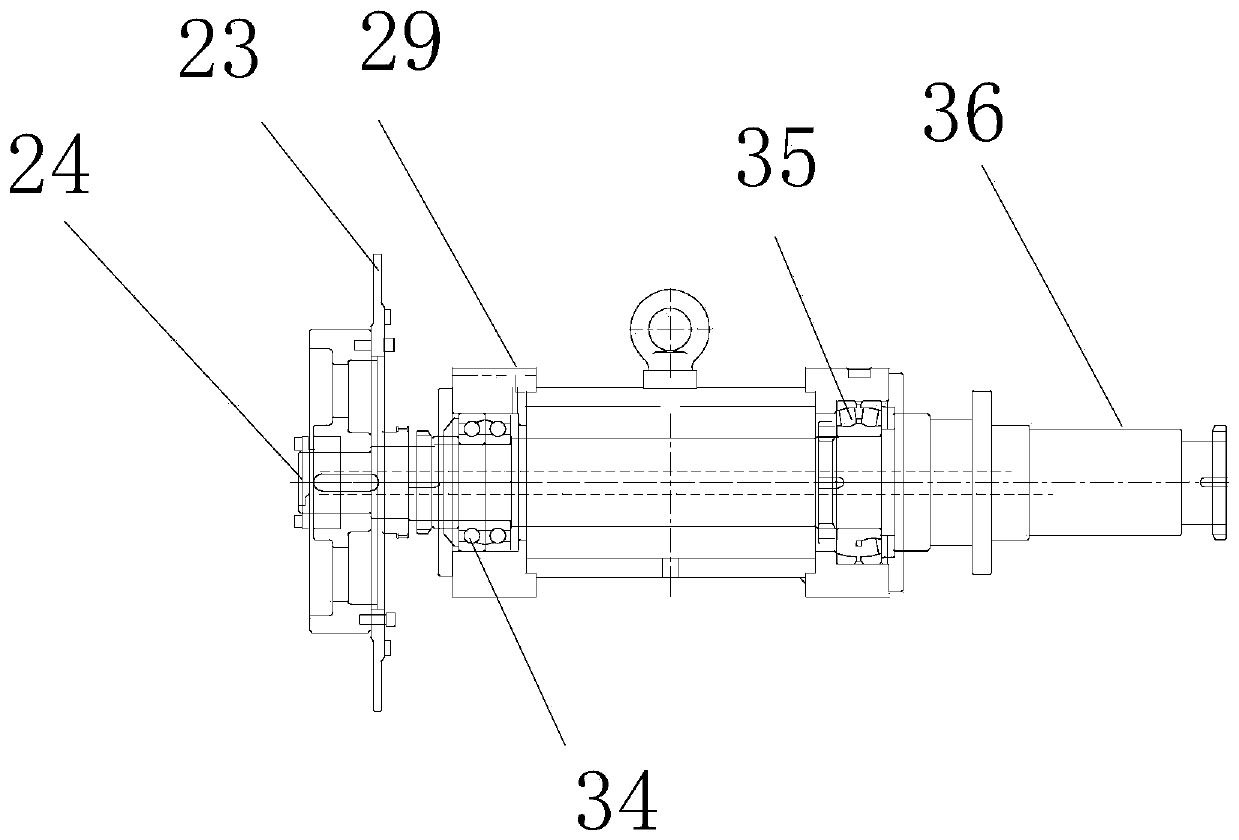

[0037] Example 1 as figure 1 As shown, the energy-saving cantilever single twisting machine of the present embodiment includes a fixed box body 11, a hollow main shaft 24, a movable box body 12, a sliding seat 41, a take-up main shaft 42, and a pallet lifting mechanism, and the main shaft motor is arranged on the fixed box body 11. 21 and the main shaft support, the main shaft bearing seat 29 is set on the main shaft support, as image 3As shown, the main shaft bearing seat 29 rotates and cooperates with the tail of the main shaft 24 through the single-row angular joint ball bearing 34, and the main shaft bearing seat 29 rotates and cooperates with the front part of the main shaft 24 through the self-aligning roller bearing 35, so that the front and rear of the main shaft 24 end protrudes from the main shaft bearing seat 29, and the main shaft motor 21 is driven and matched with the tail end of the main shaft 24 through the main shaft belt 22, so that the main shaft motor 21 c...

Embodiment 2

[0046] The working method of the above-mentioned energy-saving cantilever single winch comprises the following steps:

[0047] A. The tray 7 is fixedly connected to the screw nut 64 through the guide pin, and the lifting motor 62 is started to lower the tray 7 until the tray bottom plate 72 touches the ground. Motor 62 drives pallet 7 to rise.

[0048] B, start translation motor, drive sliding seat 41 to move by translation screw rod, make take-up shaft 42 insert the center of wire reel, cover wire reel gland 43 and make wire reel and take-up shaft 42 be fixedly connected.

[0049] C. Start the lifting motor 62 to lower the tray 7, so that the wire reel is separated from the tray 7; the cable 10 to be wound is passed through the main shaft 24 and introduced into the first guide wheel 31, the second guide wheel 32, and the third guide wheel 33 in sequence , the cable 10 is introduced into the wire reel by the third guide wheel 33, and the take-up shaft motor 45 and the transla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com