Filler type falling film uniform distributor

A packing type and distributor technology, applied in evaporator accessories, fluid circulation arrangements, refrigeration components, etc., can solve the problems of uneven gas-liquid mixing and unbalanced liquid output, so as to achieve consistent spraying volume and structure Simple, accelerated settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

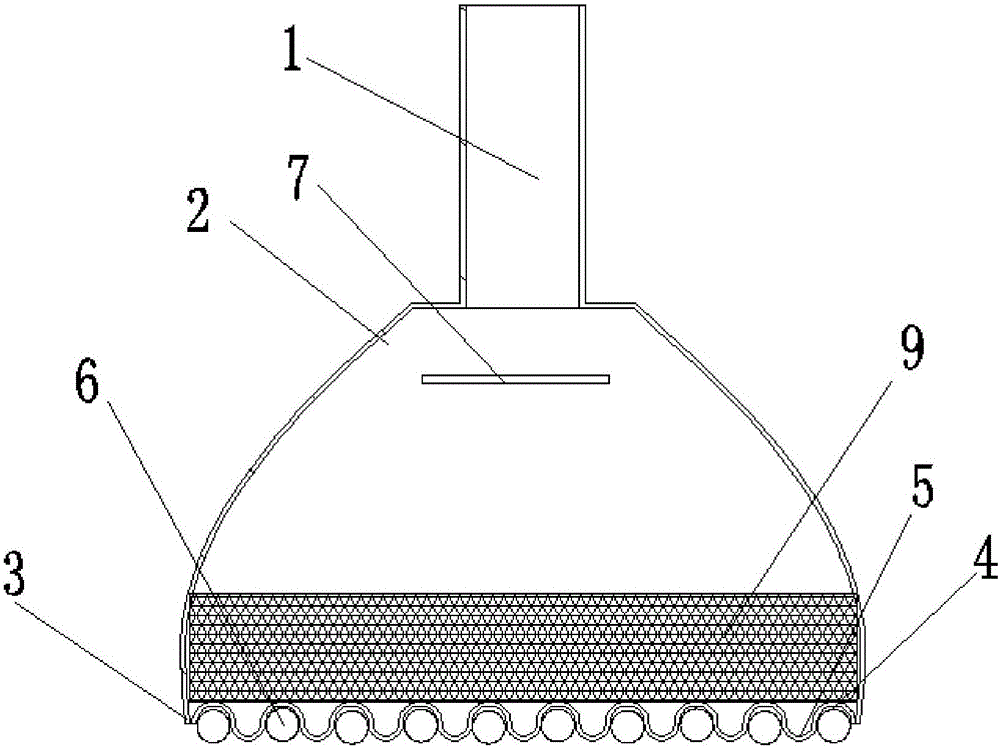

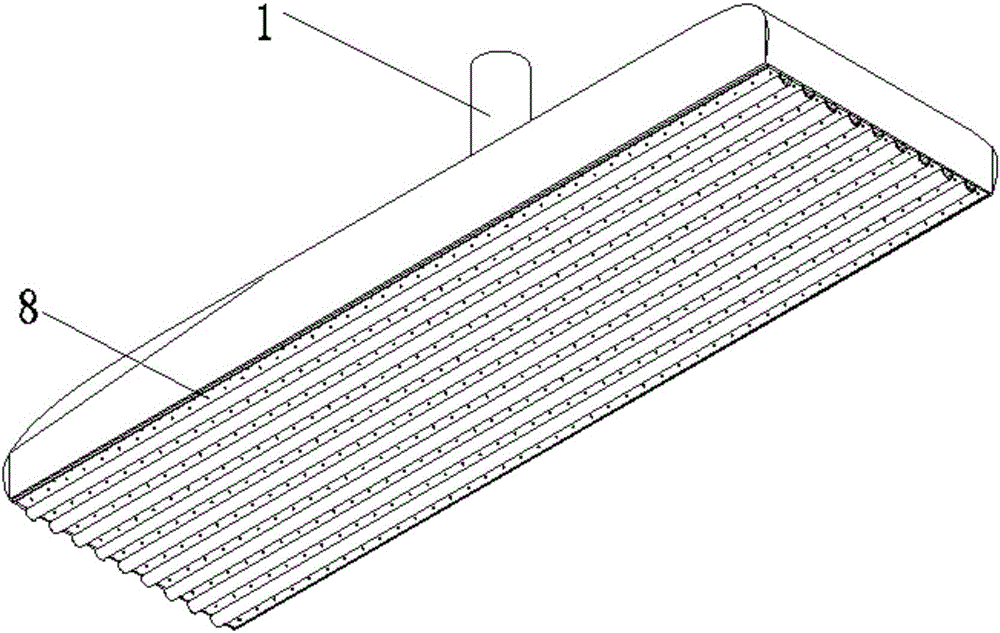

[0044] refer to Figure 1 to Figure 2 As shown, the packing type falling film uniform distributor includes a liquid inlet pipe 1, and a distribution groove 2 is arranged below the liquid inlet pipe 1, and the distribution groove 2 is tapered;

[0045] When in use, the gas-liquid mixture flows from the liquid inlet pipe 1 into the distribution tank 2. Because the liquid needs to settle down, the distribution tank 2 is designed to be tapered, so that the flow area can be increased;

[0046] Because only when the volume of the distribution tank is large, the flow rate of the gas can suddenly drop, and the distribution tank is tapered, so that the air flow can be changed from a vertical flow direction to an oblique flow direction, changing the flow direction of the gas, so it can rely on inertia The effect makes the liquid separate and settle down, and the distribution groove is conical, and the lower port becomes larger, which can expand the area of liquid spraying and improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com