High-speed wide board detection method

A detection method and technology for sheet metal, which are applied in measurement devices, analytical materials, optical testing flaws/defects, etc., can solve the problems of poor accuracy and reduction degree, large variation range of width and size, and small detection error requirements, and achieve accelerated speed. Processing speed, simple method, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

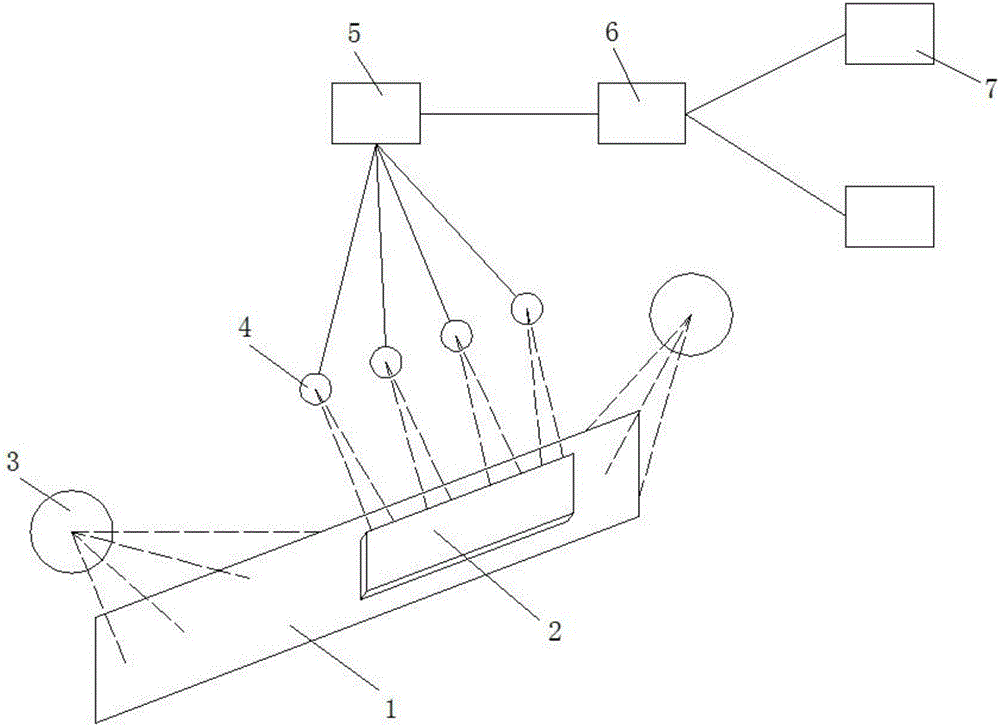

[0030] refer to Figure 1-4 , the present embodiment proposes a high-speed wide plate detection method, including the following steps:

[0031] S1: Place the wide plate 2 on the high-speed conveyor belt 1, and install diffuse reflection light sources 3 on both ends of the high-speed conveyor belt 1; because the plate is in a high-speed motion state at this time, the speed of the plate is fast and the surface light cannot be constant, it is easy Due to the accuracy of plate quality evaluation due to light reflection, diffuse reflection light source 3 is used.

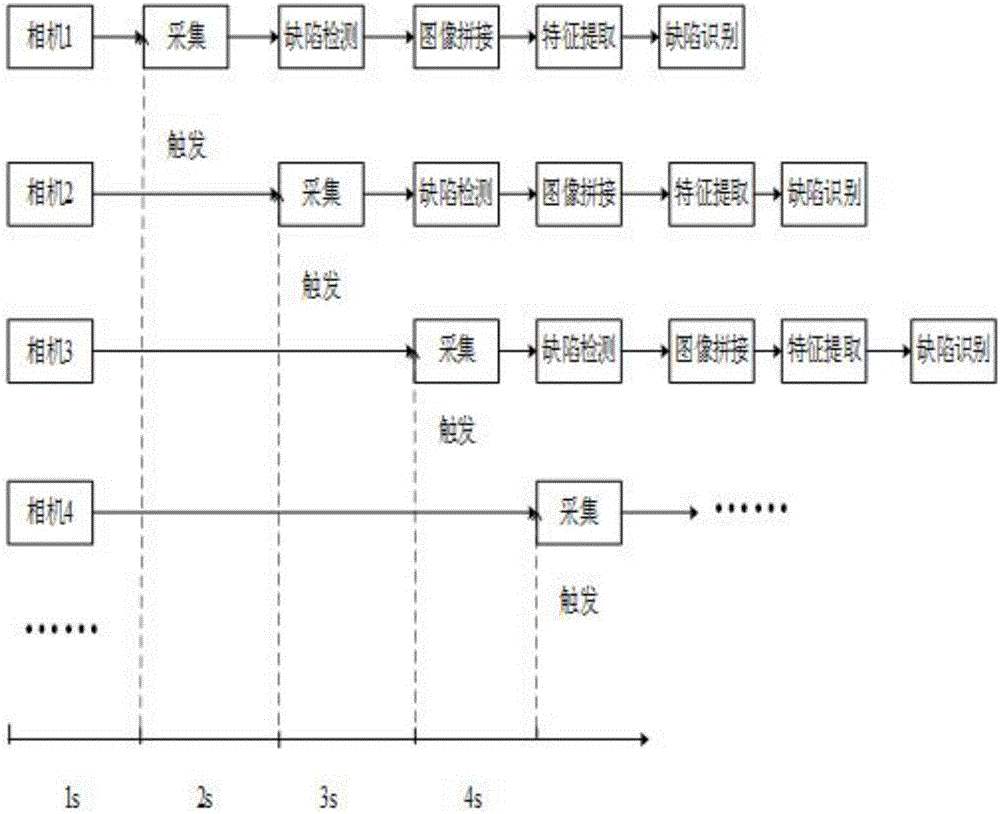

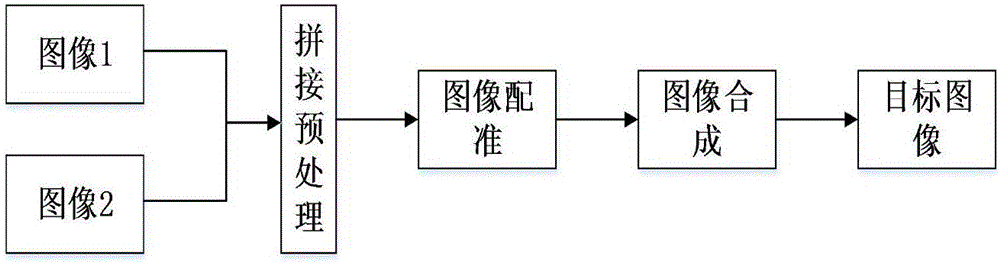

[0032] S2: On the plate detection line, after the wide plate 2 enters the detection process, the image acquisition module is used to collect the image of the wide plate 2; to improve the detection speed, multi-camera splicing is used for processing; a single The cameras collect the images within 1 second separately, and then process them separately. In the multi-camera continuous inspection state, use the splicing metho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap