Method for determining normal contact rigidity of loaded joint part by considering interaction effect of micro-bulges on rough surfaces

A technology of contact stiffness and rough surface, which is applied in the field of determining the normal contact stiffness of mechanical joints, can solve problems such as inaccurate calculation of joint contact stiffness, achieve the advantages of scale independence, wide application range, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

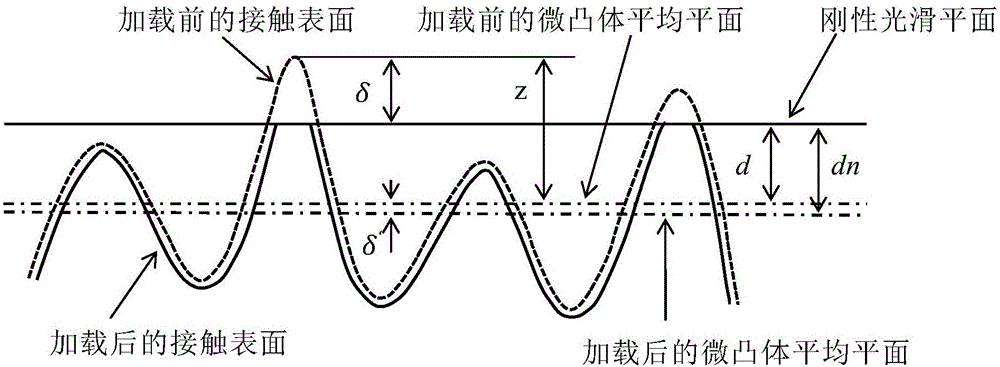

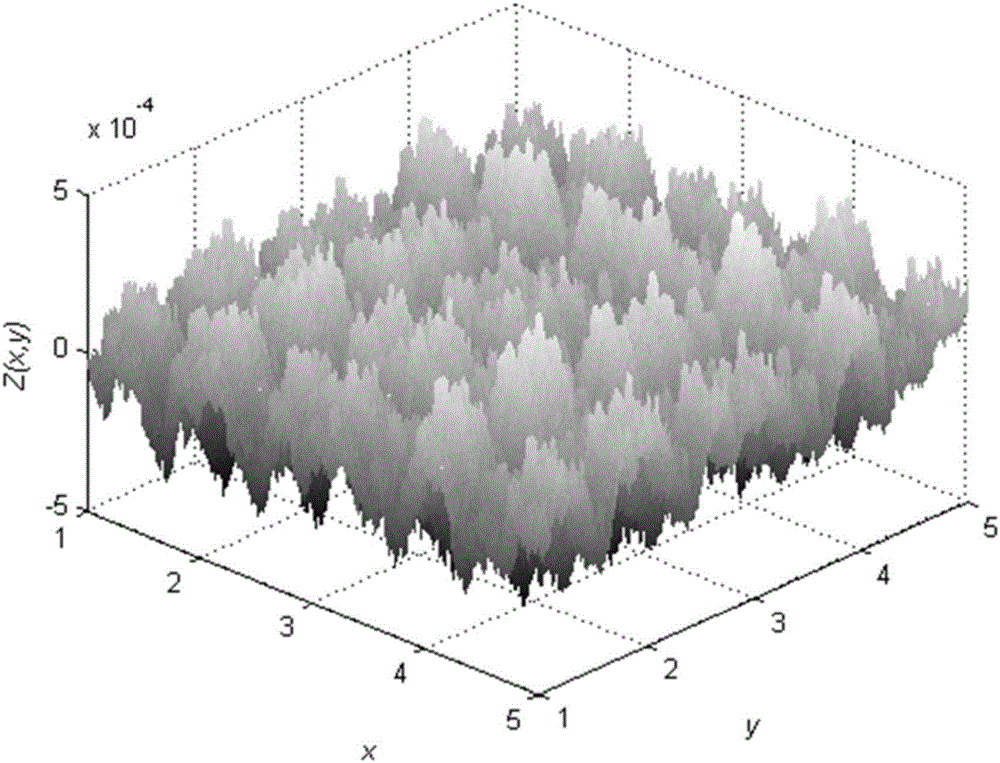

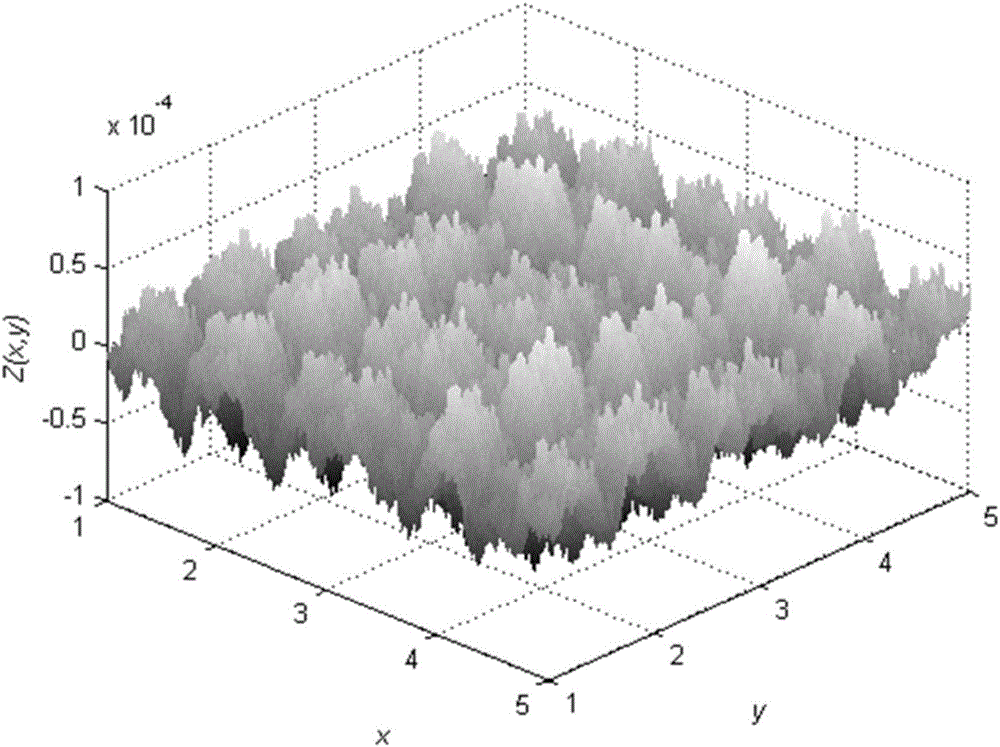

[0163] Taking two different rough surfaces as an example, the microscopic surface topography of the local regions of the two rough surfaces simulated by numerical software is as follows: figure 2 , image 3 shown. The material parameters of contact surface 1 are as follows: Elastic modulus E 1 =130Gpa, Poisson's ratio v 1 =0.3, yield strength σ y1 =300MPa, hardness H 1 =1200MPa; the material parameters of contact surface 2 are as follows: modulus of elasticity E 2 =130Gpa, Poisson's ratio v 2 =0.3, yield strength σ y2 =260MPa, hardness H 2 =740 MPa. The normal load applied to the junction P=1×10 4 Pa.

[0164] Set the number of collection points to 500, and substitute the collected contour height data into the discrete structure function expression to draw the discrete structure function images of the two contact surfaces, and regression analysis in log-log coordinates can obtain the fitting curve The slope and intercept of , and its visualization results are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com