3D printed water-permeable pavement scale simulation device and method under action of runoff

A permeable pavement and 3D printing technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of reduced water permeability, poor repeatability, increased urban floods and freeze-thaw disasters, etc., to achieve high reuse rate, good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

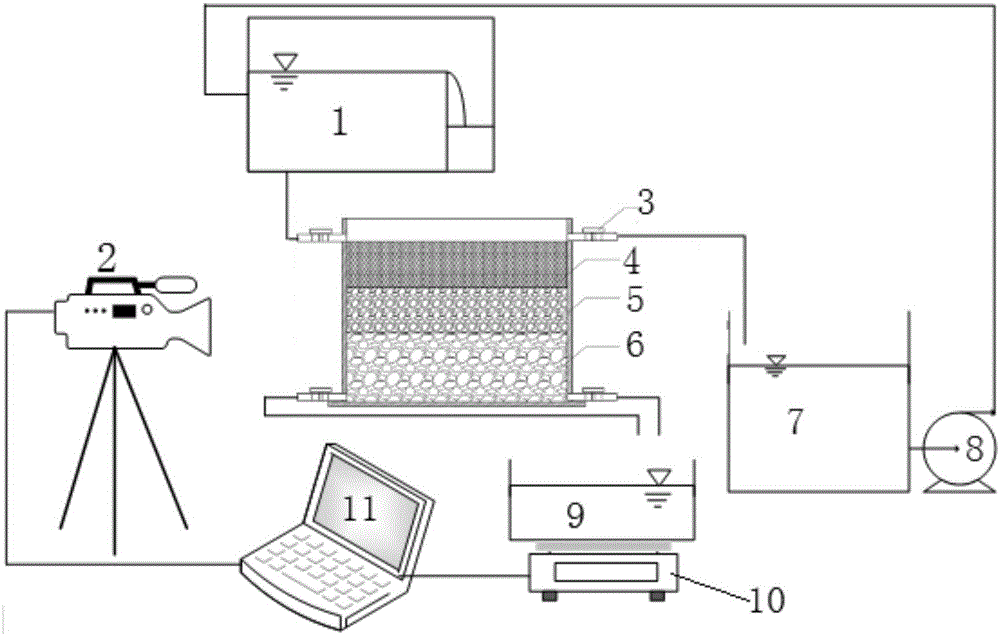

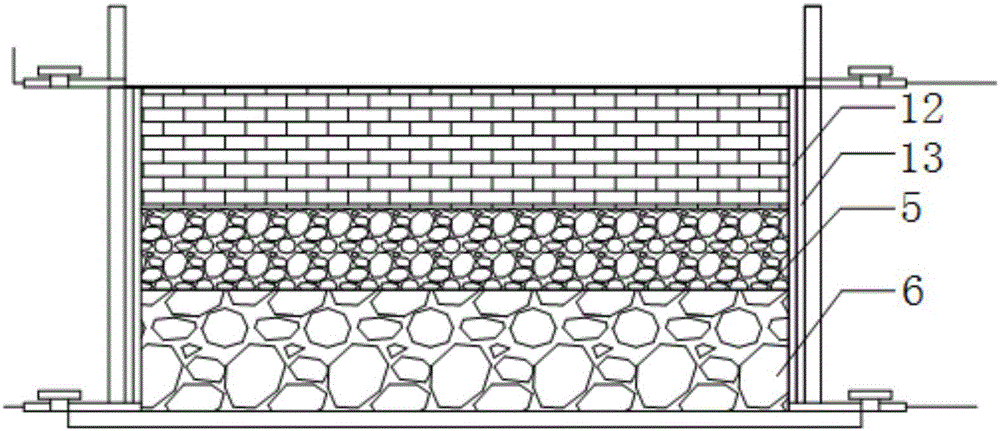

[0042] 3D printing permeable pavement scale simulation device under the action of runoff, such as figure 1 and figure 2As shown, it includes a model box with an opening on the top. In the model box, the lower base layer 6, the upper base layer 5, and the 3D printed permeable pavement 4 are arranged in sequence from the bottom to the top. The permeable pavement is transparent or translucent. Slices are scanned and reconstructed in a 3D printer to make a 3D printed permeable pavement 4; a seepage port is set at the bottom of the model box, and the seepage port is connected to the collector 9, and a constant water head water supply tank is provided on the top side of the model box 1 connected to the water inlet, and the other side is provided with a drain connected to the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com