Transparent substrate full-color LED (light emitting diode) display screen and production technology

A technology of LED display screen and transparent substrate, applied in the direction of identification devices, instruments, etc., can solve the problems of increasing the probability of failure, affecting the beauty of walls and buildings, and reducing light transmittance, improving transparency and viewing angle defects, and improving installation. A single way, the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

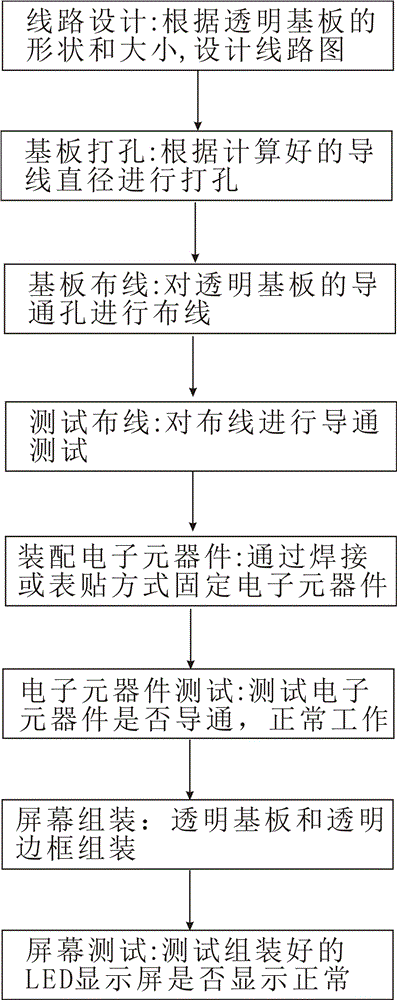

[0021] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 , the invention discloses a full-color LED display with a transparent substrate, including a transparent substrate and a transparent frame, the transparent substrate is fixed on the building through the transparent frame, and the transparent frame can also play a role in protecting the internal transparent substrate, such as The role of waterproof. In this embodiment, the transparent substrate can be a double-layer or multi-layer transparent substrate, which is a transparent glass substrate, or a transparent ceramic substrate or a transparent plastic substrate. In order to highlight the plasticity and bendability of the entire LED display screen, it is preferred A transparent plastic substrate is selected, and the entire transparent substrate is the display screen. Since the transparent substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com