Implement end bit wear member

A technology for components and tools, applied in the field of ground engaging tools, can solve problems such as affecting the penetration of working surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

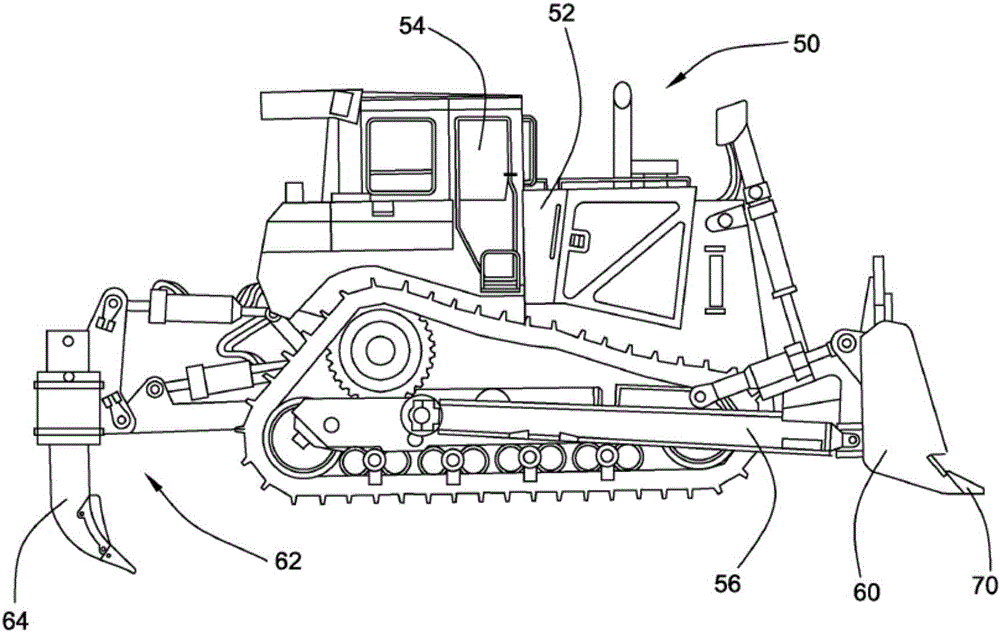

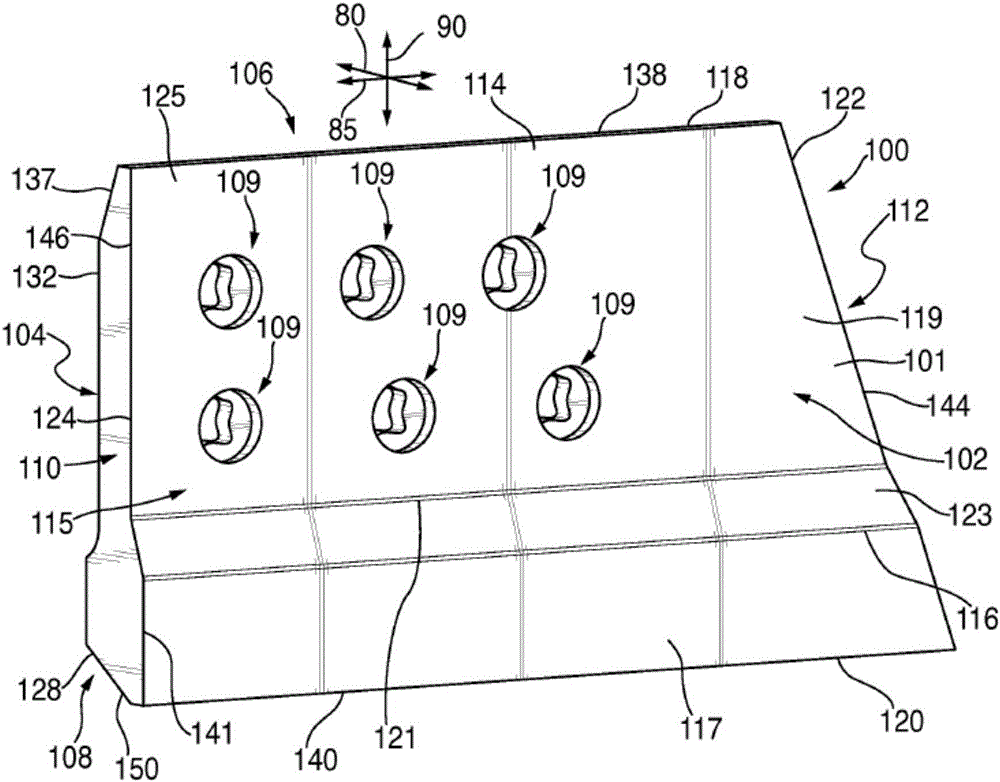

[0036] The present invention relates to ground engaging tool assemblies and systems, and more particularly to earth moving tool wear members, cutting bits, or cutting edges for use in various types of mining machines, earth moving machines, and construction machines. figure 1 An embodiment of a machine 50 in the form of a track-type tractor is shown that may include an embodiment of an implement wear member 100 constructed in accordance with the principles of the invention. Track-type tractors may be used to move and remove work material in a variety of surface mining or other construction applications, among other uses.

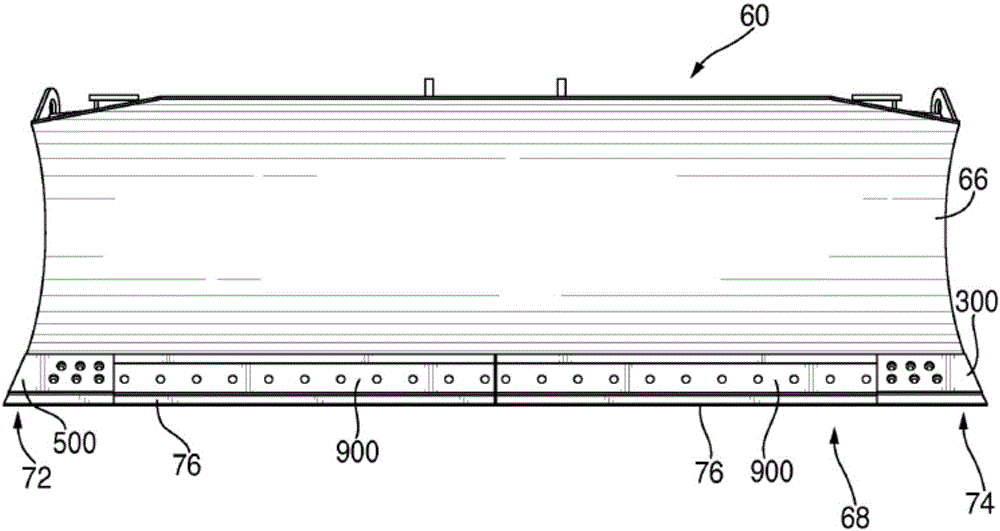

[0037] as in figure 1 As shown in , a machine 50 may include a main body 52 having a cab 54 for housing a machine operator. Machine 50 may also include an arm system 56 pivotally connected at one end to body 52 or chassis and supporting earth moving tool assembly 60 at an opposite distal end. In embodiments, implement assembly 60 may include any suitable i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com