Drillable hollow core well cementing rubber plug

A cementing rubber plug and hollow core technology, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc. Work efficiency and the effect of reducing drilling safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

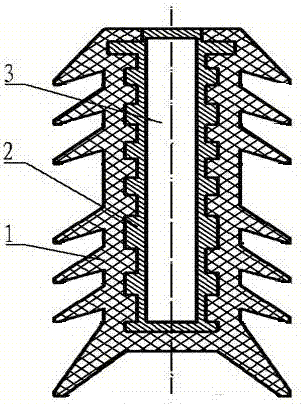

[0011] Such as figure 1 As shown, a drillable hollow cementing rubber plug is characterized by a rubber wing 1 , a drillable metal core 2 and a metal core hollow 3 . Drillable metal core 2 is surrounded by vulcanized rubber rubber wings 1, and the periphery of drillable metal core 2 is rectangular, which is integrated with the surrounding vulcanized rubber and is not easy to fall off. The metal core hollow core 3 can be made in the middle of the drillable metal core 2, with a length of 260 mm and a diameter of 80 mm.

[0012] The working principle of a drillable hollow cementing rubber plug of the present invention is: during the cementing construction process, the rubber plug goes down, and the rubber wing 1 clings to the inner wall of the casing, while separating the cement slurry from the replacement medium, the casing Scrape off any deposits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com