Flaxseed noodles and preparing method thereof

A technology of flaxseed and flaxseed powder, applied in food science and other directions, can solve the problems of stiff and chewy noodles, unsuitable noodles for consumers, poor food safety, etc., and achieves chewy taste, golden color and smooth taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

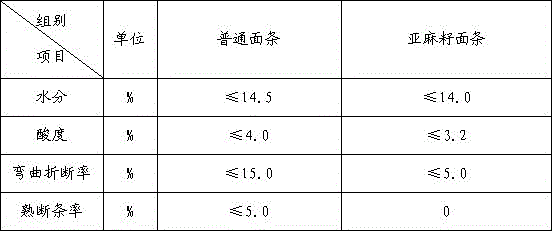

Image

Examples

Embodiment 1

[0021] A flaxseed noodle made from the following raw materials by weight, including 1000 grams of wheat flour, 75 grams of flaxseed meal, 350 grams of water and 25 grams of salt.

[0022] A preparation method of linseed noodles, comprising the following steps:

[0023] 1) Take 1000 grams of wheat flour and 75 grams of flaxseed flour and put them into the grinder together, and control the grinder to grind slowly at a speed of 45r / min, so that the wheat flour and flaxseed flour are ground at room temperature into 60-mesh mixed flour for later use ;

[0024] 2) Kneading noodles: A. Handmade: Take 350 grams of water and heat it to 100°C through a kettle, then add 25 grams of salt, stir quickly with chopsticks to melt the salt, then let the boiling water stand and cool to room temperature water at 30°C, then add Mix and stir the 60-mesh flour prepared in step 1) to make dough; B. Machine production: take 300 grams of water and heat it to 30°C through a kettle, then add 25 grams of...

Embodiment 2

[0032] A flaxseed noodle made from the following raw materials by weight, including 1000 grams of wheat flour, 75 grams of flaxseed meal, 350 grams of water and 25 grams of salt.

[0033] A preparation method of linseed noodles, comprising the following steps:

[0034] 1) Take 1000 grams of wheat flour and 75 grams of flaxseed flour and put them into the grinder together, and control the grinder to grind slowly at a speed of 45r / min, so that the wheat flour and flaxseed flour are ground at room temperature into 60-mesh mixed flour for later use ;

[0035] 2) Kneading noodles: A. Handmade: Take 350 grams of water and heat it to 100°C through a kettle, then add 25 grams of salt, stir quickly with chopsticks to melt the salt, then let the boiling water stand and cool to room temperature water at 30°C, then add Mix and stir the 60-mesh flour prepared in step 1) to make dough; B. Machine production: take 300 grams of water and heat it to 30°C through a kettle, then add 25 grams of...

Embodiment 3

[0043] A flaxseed noodle made from the following raw materials by weight, including 1000 grams of wheat flour, 75 grams of flaxseed meal, 350 grams of water and 25 grams of salt.

[0044] A preparation method of linseed noodles, comprising the following steps:

[0045] 1) Take 1000 grams of wheat flour and 75 grams of flaxseed flour and put them into the grinder together, and control the grinder to grind slowly at a speed of 45r / min, so that the wheat flour and flaxseed flour are ground at room temperature into 60-mesh mixed flour for later use ;

[0046] 2) Kneading noodles: A. Handmade: Take 350 grams of water and heat it to 100°C through a kettle, then add 25 grams of salt, stir quickly with chopsticks to melt the salt, then let the boiling water stand and cool to room temperature water at 30°C, then add Mix and stir the 60-mesh flour prepared in step 1) to make dough; B. Machine production: take 300 grams of water and heat it to 30°C through a kettle, then add 25 grams of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com