Degassing filter

A filter and filter cartridge technology, which is applied in the direction of fixed filter element filter, filter separation, filter circuit, etc., can solve the problem of incomplete exhaust of the getter filter, so as to facilitate daily maintenance, facilitate instrument maintenance, and prolong the use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

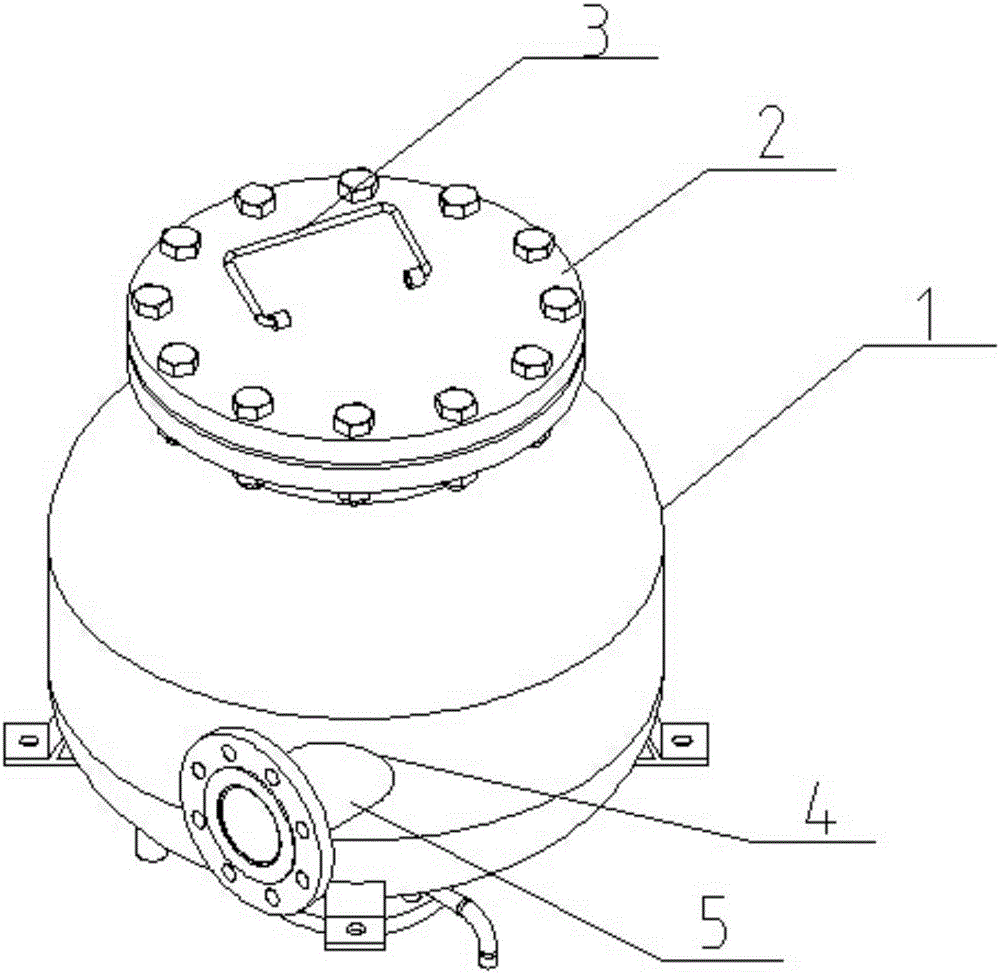

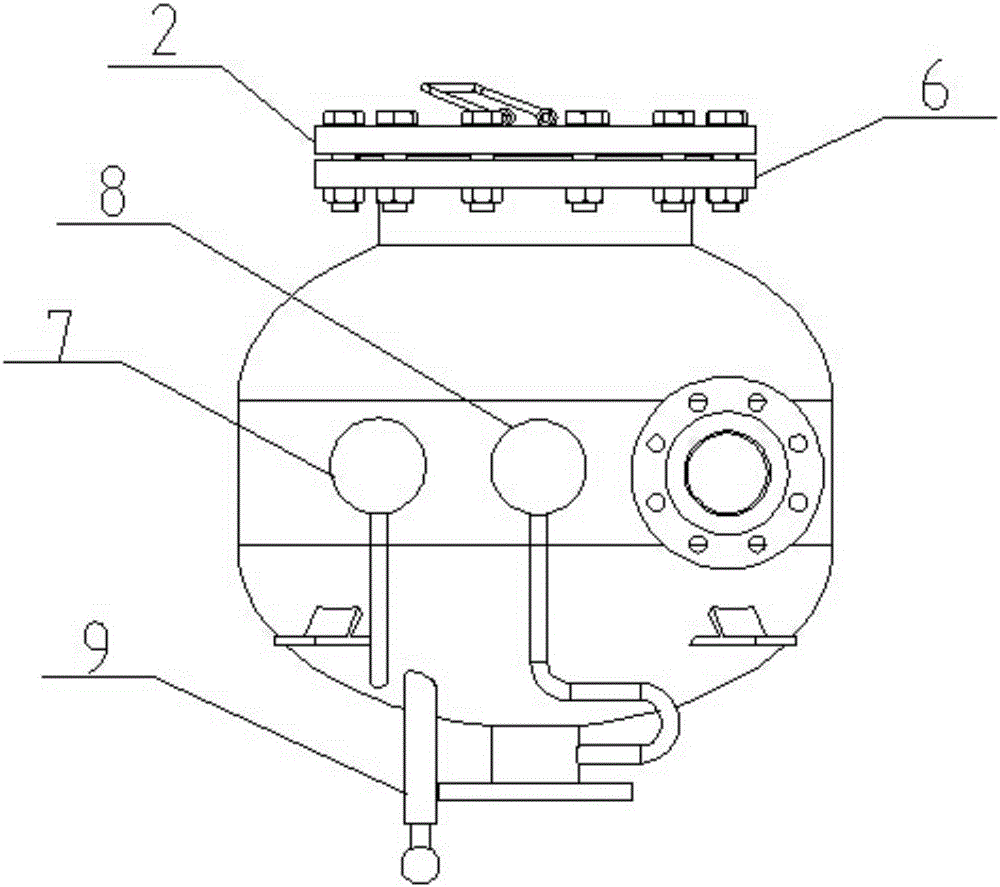

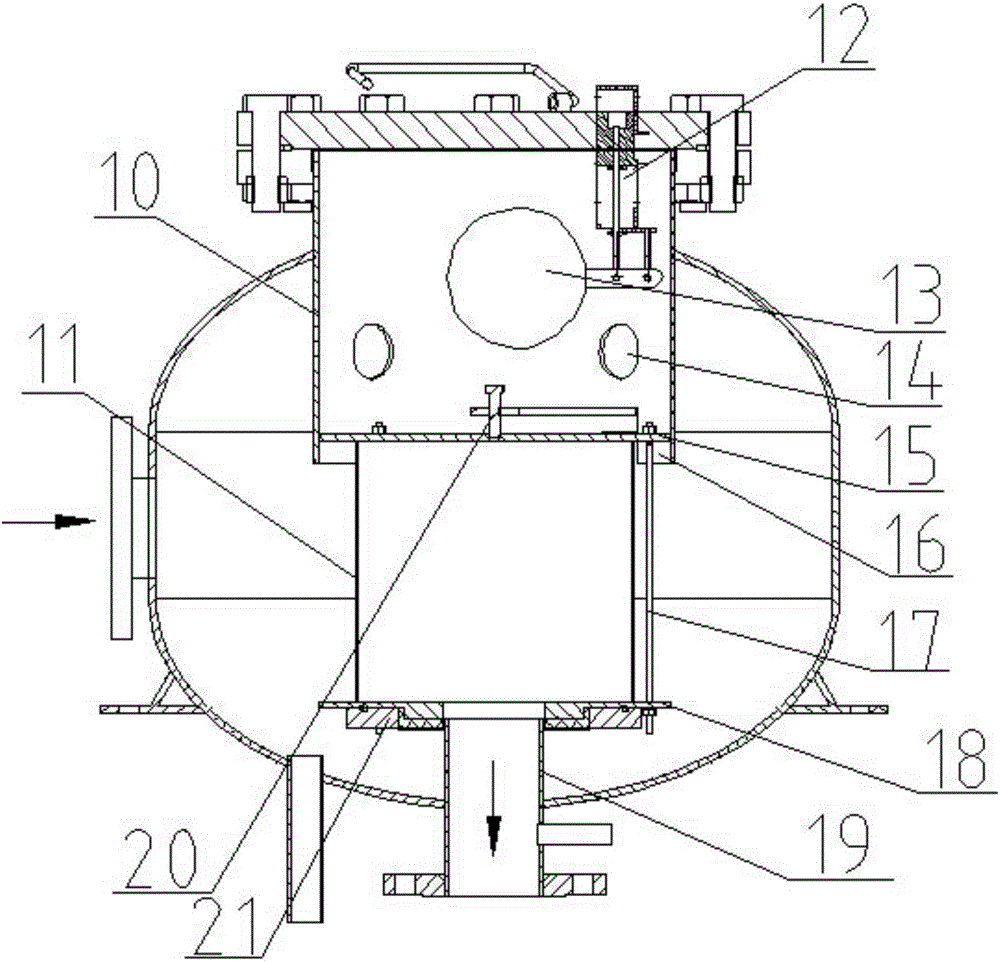

[0031] A degassing filter, comprising a cylinder 1 and an inlet 4 arranged on one side of the cylinder 1, a filter cartridge 11 is arranged inside the cylinder 1, and the top of the filter cartridge 11 is fixedly connected to an exhaust device and communicated with the exhaust device, The inlet 4 is arranged tangentially along the side wall of the cylinder body 1; the top of the cylinder body 1 is provided with an opening that cooperates with the exhaust device, and the exhaust device includes an inner cylinder 10, and the top of the inner cylinder 10 passes through the opening and Extending to the outside of the cylinder body 1, the top of the inner cylinder 10 is provided with a sealing device, the sealing device is provided with an exhaust port and an exhaust valve 12 installed at the exhaust port, and the inner cylinder 10 is also provided with an exhaust valve. The floating ball 13 matched with the air valve 12; diversion openings 14 are evenly distributed on the side wall...

Embodiment 2

[0034] Based on Embodiment 1, an inlet pipe 5 is provided at the inlet 4, and the inlet pipe 5 is used to connect the oil pipeline. The inlet pipe 5 is inclined downward at an angle of 17°, so that when the oil enters the barrel 1 at high speed, a swirl flow 22 is formed upward along the inner wall, which is beneficial for the oil to enter the inner barrel 10 from the diversion port 14 .

Embodiment 3

[0036]Based on Embodiment 1, the sealing device is a top cover 2 , and a third flange 6 is connected to the top of the inner cylinder 10 , and the top cover 2 and the inner cylinder 10 are bolted through the third flange 6 . The top of the inner cylinder 10 can be sealed through the top cover 2 and the third flange 6 to ensure gas accumulation on the upper part of the inner cylinder 10, and the bolt connection is a detachable fixed connection, which has the advantages of simple structure, reliable connection, and convenient disassembly. It is convenient to overhaul and clean the exhaust device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com