Dimple Coating System and Its Coating Width Control Device

A width control and coating technology, applied in the field of coating system, can solve the problems of glue waste, uneven material edge thickness, affecting lamination and winding, etc., to avoid glue waste, avoid uneven thickness, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

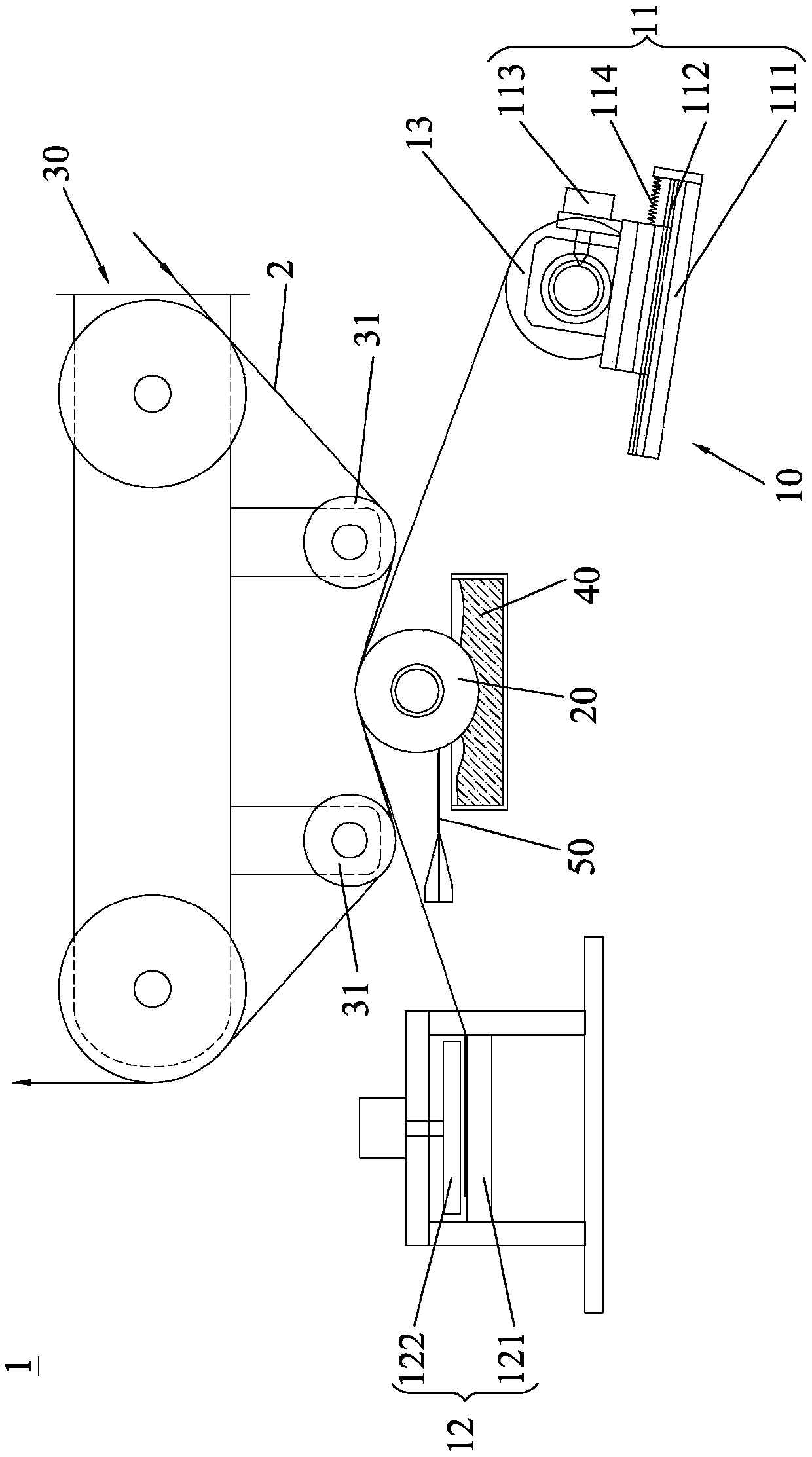

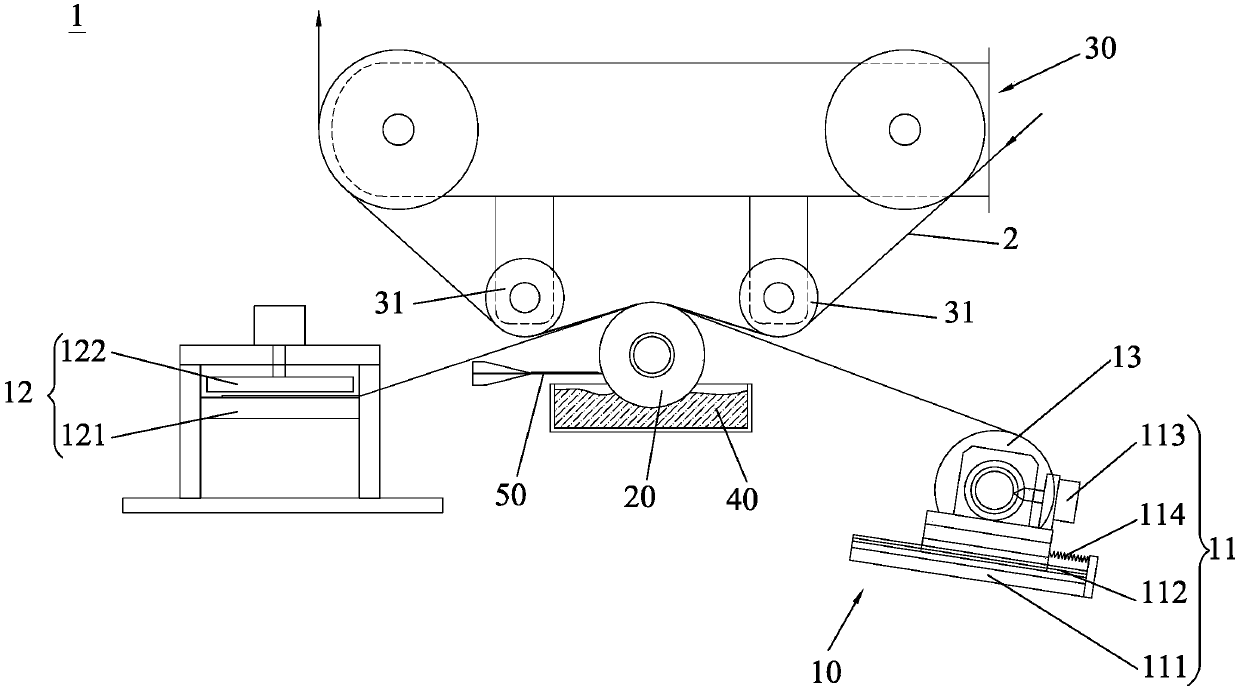

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The coating width control device 10 provided by the present invention is applicable to the dimple coating system 1 , but is not limited thereto, and can also be used in other coating equipment.

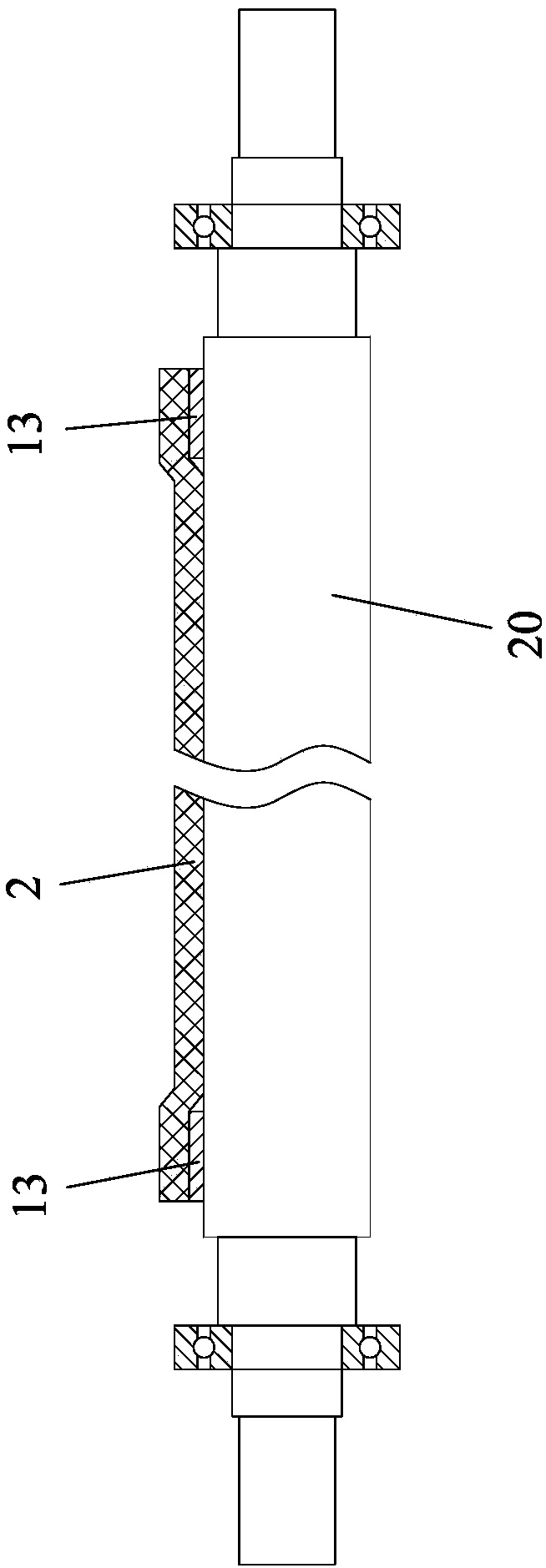

[0019] First combine the following Figure 1-2 As shown, a dimple coating system 1 provided by the present invention includes a dimple roller 20 , a guide mechanism 30 , a glue supply tank 40 , a scraper 50 and two coating width control devices 10 . Wherein, the guiding mechanism 30 comprises a plurality of guiding rollers 31 arranged at intervals, and the guiding rollers 31 are used to guide the material 2 to be coated; The axial direction of the roller 31 is consistent, and a channel for the material 2 to be coated is formed between the micro-concave roller 20 and the guide roller 31. When the material 2 passes through, the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com