Soil treatment device adopting spraying manner

A soil and production device technology, applied in the field of soil pollution control, can solve problems such as incomplete land treatment, and achieve the effects of increasing temperature, saving energy, and solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

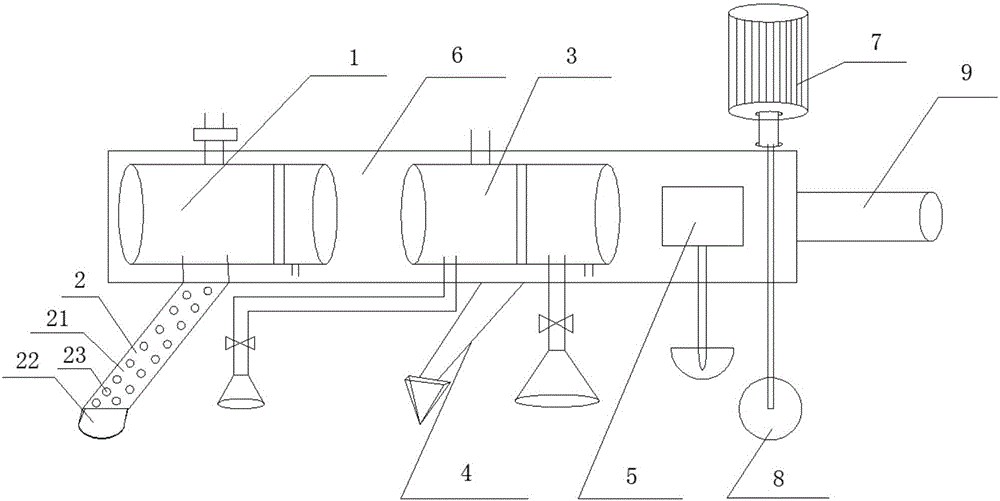

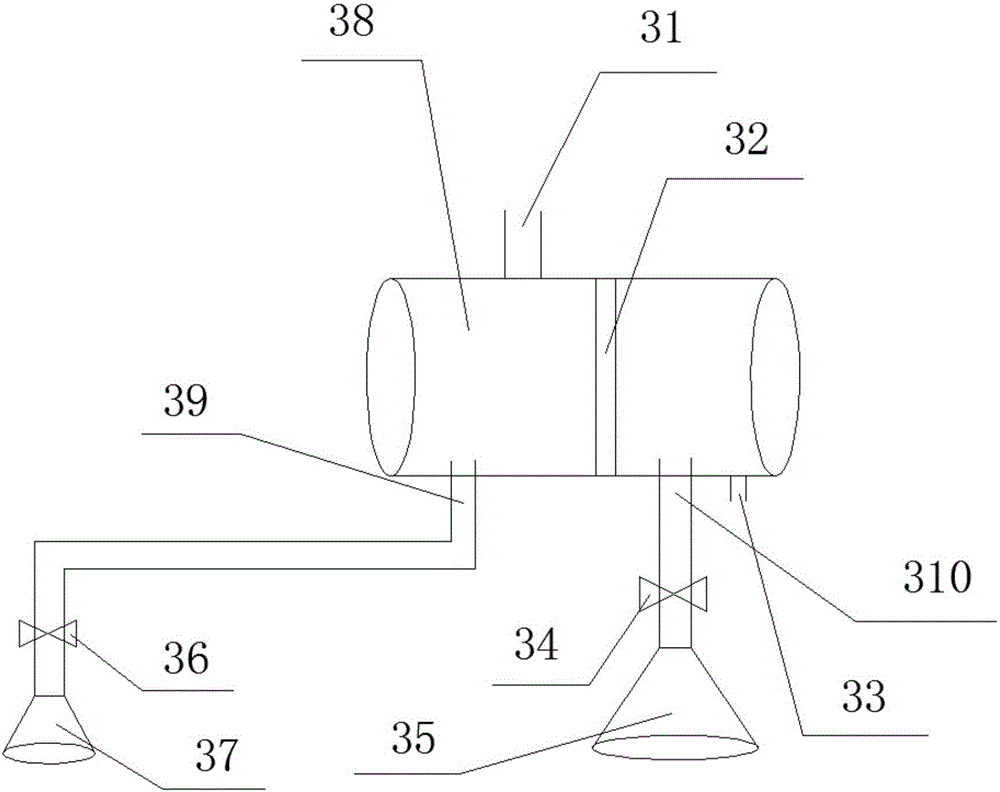

[0027] This embodiment combines the attached figure 1 And attached image 3 To describe in detail, a soil treatment device adopting a spraying method includes a box body 6, a drug application device 3 connected to the box body 6, and a driving device 7; the drug application device 3 is arranged in the box body 6; The lower end of the box body 6 is connected with a soil planing structure 2, a soil crushing structure 4 and a rolling structure 8 arranged in sequence; the lower end of the box body 6 is also provided with a heat generating device 5, and the heat generating device 5 is arranged on the Between the drug application device 3 and the rolling structure 8, a handle 9 is provided at one end of the box body 6; the driving device 7 is connected to the rolling structure 8; the drug application device 3 includes a drug storage tank 38, The medicine tank 38 is provided with a medicine inlet 31, a medicine first outlet 39, a medicine second outlet 310, a second sewage outlet 33...

Embodiment 2

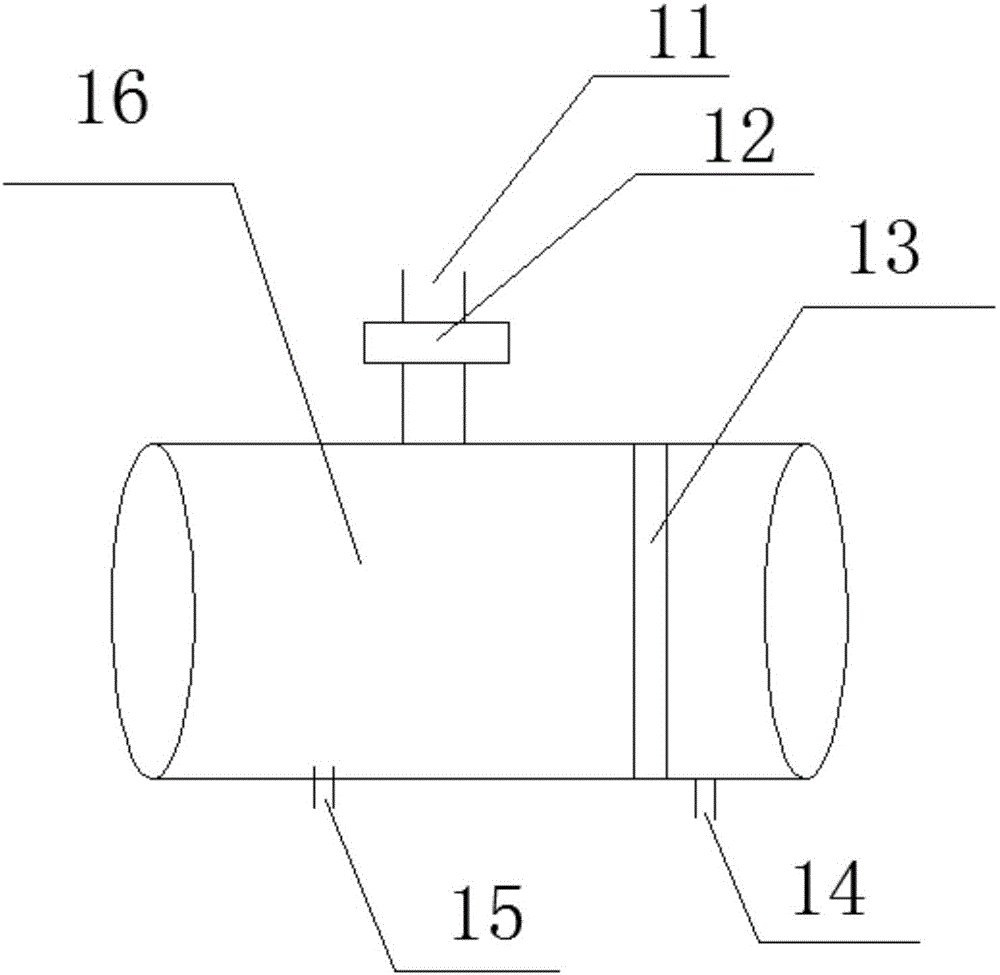

[0030] The technical solution of this embodiment is: the soil treatment device using spraying method also includes a sprinkler 1 connected to the soil planing structure 2, the sprinkler 1 is arranged in the box 6 and the sprinkler 1 It is arranged on the left side of the spraying device 3; the sprinkling device 1 includes a water storage tank 16, and the water storage tank 16 is provided with a water inlet 11, a water outlet 15, a first sewage outlet 14 and a second liquid level Meter 13; the water inlet 11 is provided with a filter structure 12; the water outlet 15 is connected to the soil planing structure 2.

[0031] This embodiment combines the attached figure 1 And attached figure 2 In detail, the filtering structure 12 of the water inlet 11 of the sprinkler 1 on the left side of the spraying device 3 in the casing 6 can filter out impurities in the water to avoid blocking the water outlet 15 and the water outlet; the second The liquid level gauge 13 monitors the water...

Embodiment 3

[0033] This embodiment combines the attached Figure 4 In detail, the heat generating device 5 includes a switch 51 connected in sequence, a lamp post 52 and a sealed lamp cover 54, the lower end of the lamp post 52 is connected with a bulb 53, and the bulb 53 is arranged in the sealed cover 54; The upper inner surface of the sealed lampshade 54 is provided with a heat insulating layer.

[0034] The switch 51 is used to control the stop and work of the heat generating device 5, and the inner surface of the upper part of the sealed lampshade 54 is provided with a heat insulating layer, so as to avoid other places from being heated except the soil and save energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com