Fence pile continuous rolling unit

A continuous rolling and fence technology, applied in metal rolling, metal rolling and other directions, can solve problems such as large consumption of raw materials, large investment in manpower, hidden dangers of steel safety, etc., to reduce unsafe factors, improve product quality, and achieve a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

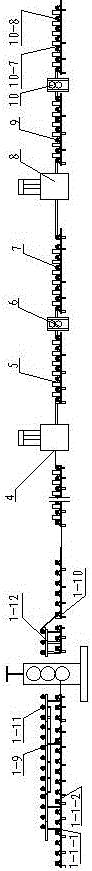

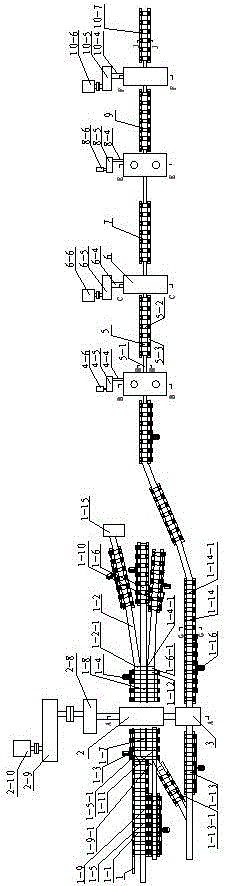

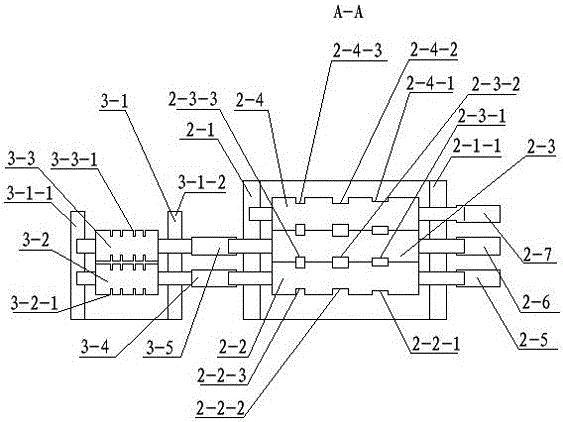

[0042] see Figure 1 to Figure 14 , The fence pile continuous rolling unit described in this embodiment includes a roughing mill, the roughing mill is a reciprocating rolling mill, and the roughing mill includes a first roughing mill 2 and a second roughing mill 3 arranged side by side. The first rough rolling mill 2 comprises the first rough rolling mill left support 2-1, the first rough rolling right support 2-1-1, and the first rough rolling roll 2-2, the second rough rolling roll 2-2 are successively arranged in the support from bottom to top 3. The third rough roll 2-4, the first rough roll 2-2, the second rough roll 2-3, and the third rough roll 2-4 are respectively provided with bearing housings. The side where the rough roll is connected to the motor is the driving side, and the side corresponding to the driving side is the working side. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com