A kind of hot-rolled round steel and preparation method thereof

A round steel and steel billet technology, applied in the field of hot-rolled round steel preparation, can solve the problems of high material cost and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

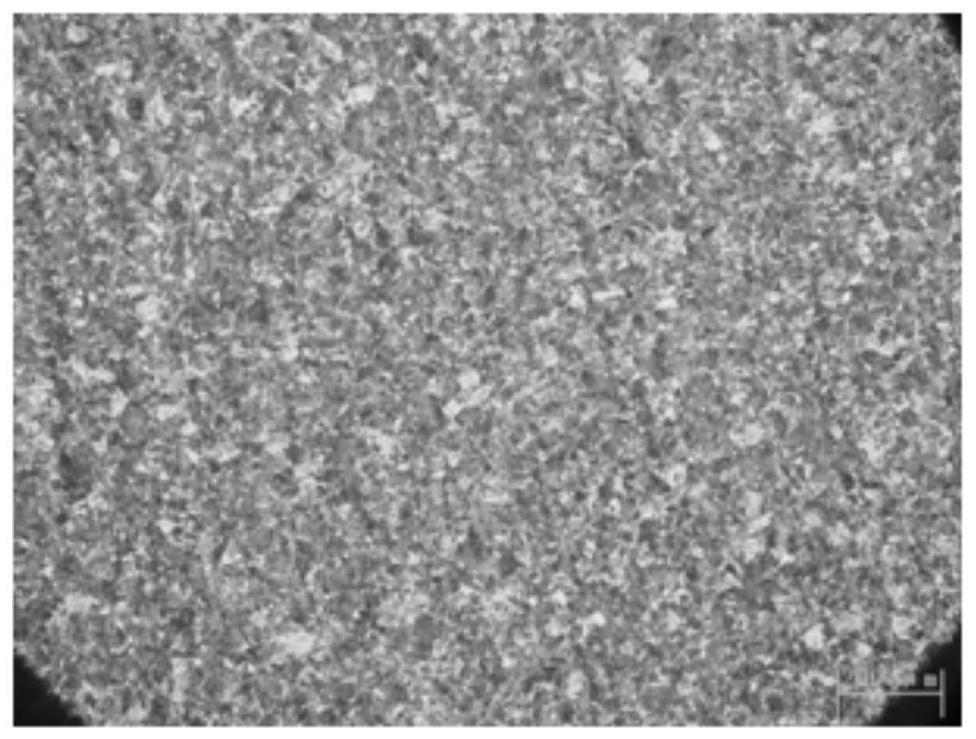

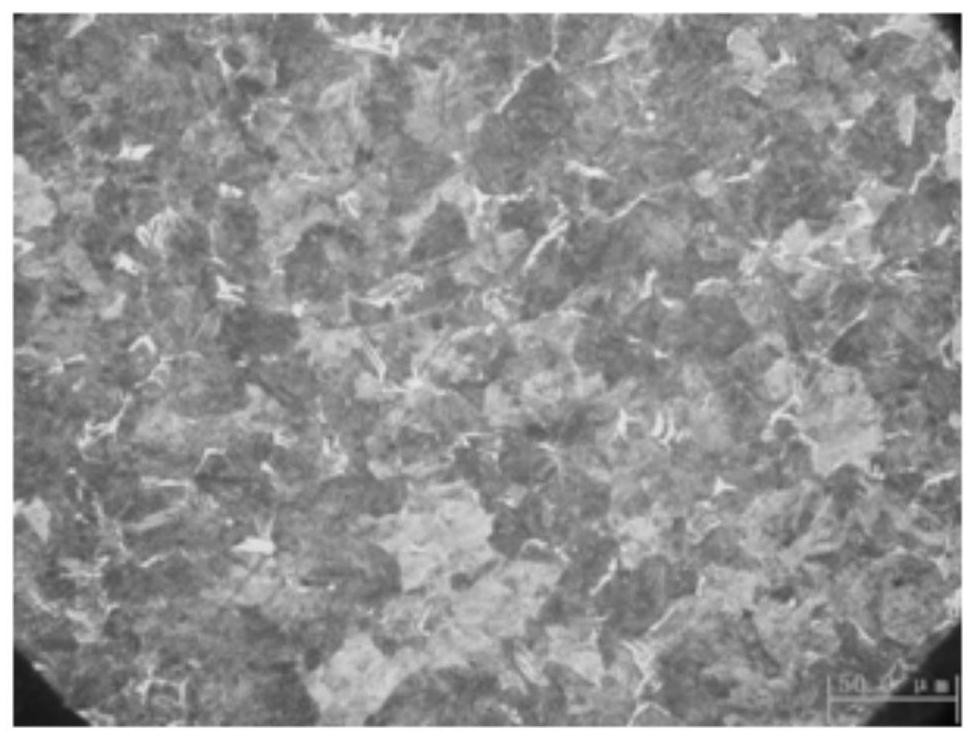

Image

Examples

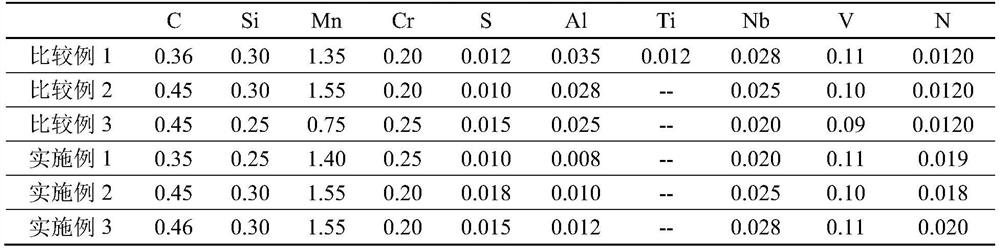

Embodiment 1

[0042] The diameter of the round steel involved in this embodiment is 60mm, and its chemical composition is calculated by mass percentage: C: 0.35%, Si: 0.25%, Mn: 1.40%, Cr: 0.25%, Al: 0.008%, S: 0.010%, Nb: 0.020%, V: 0.11%, N: 0.019%, and the balance is iron and unavoidable impurity elements.

[0043] The above-mentioned round steel is smelted in an electric furnace and LF refined in turn to produce molten steel; the molten steel is poured into a 250mm×250mm continuous casting billet with a low superheat of 15-30 °C under argon protection throughout the whole process, and the continuous casting billet is slowly cooled in the pit for 32 hours; The cast slab is heated in the furnace, the heating temperature is set to 1200°C, and the temperature is kept for 3 hours before being released from the furnace; after being released from the furnace, the forming process is divided into the following four steps:

[0044] ①The first billet is descaled by high-pressure water on the rolle...

Embodiment 2

[0050] The diameter of the round steel involved in this embodiment is 60mm, and its chemical composition is calculated by mass percentage: C: 0.45%, Si: 0.30%, Mn: 1.55%, Cr: 0.20%, Al: 0.010%, S: 0.018%, Nb: 0.025%, V: 0.10%, N: 0.0180%, and the balance is iron and unavoidable impurity elements.

[0051] The above-mentioned round steel is smelted in an electric furnace and LF refined in turn to produce molten steel; the molten steel is poured into a 250mm×250mm continuous casting billet with a low superheat of 15-30 °C under argon protection throughout the whole process, and the continuous casting billet is slowly cooled in the pit for 32 hours; The slab is heated to 1200°C, held for 3 hours and released; rolling is carried out in the following four steps:

[0052] ①The first billet is descaled by high-pressure water once and then returned to the same route, and then descaled by high-pressure water for the second time to remove all surface oxide scales and promote cooling; th...

Embodiment 3

[0058] The diameter of the round steel involved in this embodiment is 110mm, and its chemical composition is calculated by mass percentage: C: 0.46%, Si: 0.30%, Mn: 1.55%, Cr: 0.20%, Al: 0.012%, S: 0.015%, Ti: 0.012%, Nb: 0.028%, V: 0.11%, N: 0.0200%, and the balance is iron and unavoidable impurity elements.

[0059] The above-mentioned round steel is smelted in an electric furnace and LF refined to produce molten steel in turn; the molten steel is poured into a 300mm×340mm continuous casting billet with a low superheat of 15-30°C under full argon protection, and the continuous casting billet is slowly cooled in the pit for 32 hours; The slab is heated to 1200°C, held for 3.5 hours and released; rolling is carried out in the following four steps:

[0060] ①The first billet is descaled by high-pressure water once and then returned to the same route, and then descaled by high-pressure water for the second time to remove all surface oxide scales and promote cooling; then it is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com