Novel four-pillar guide amplitude modulation pressurization vibration forming system

A vibration forming and vibrating system technology, applied in material forming presses, presses, manufacturing tools, etc., can solve the problems of adverse effects on the service life of the amplitude modulation box, increase production costs, prolong production tact, and increase equipment safety. , The effect of saving labor costs and improving the bearing capacity of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

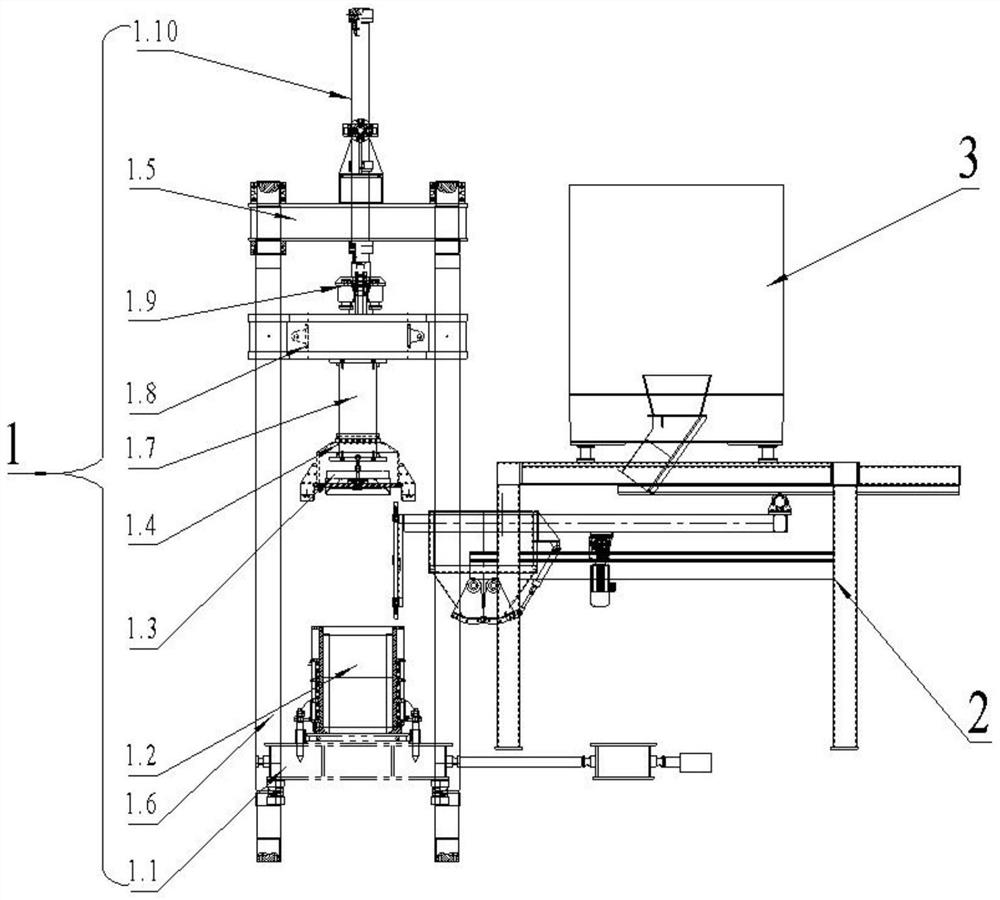

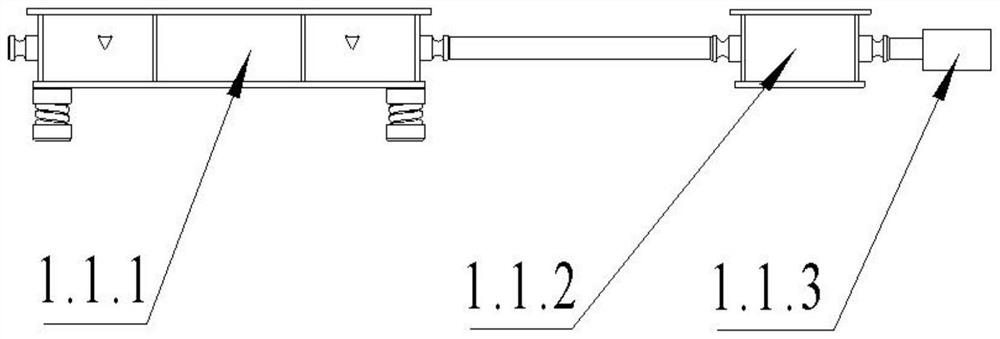

[0035] A new type of four-column guided amplitude modulation pressurized vibration forming system (see Figure 1-8 ), comprising vibration forming machine 1 and feeding system 2 for vibration forming machine 1 (see figure 1 ), the vibration molding machine 1 (see figure 2 The vibration system 1.1 of ) includes a vibration box 1.1.1, an amplitude modulation box 1.1.2 connected to the vibration box 1.1.1, and a motor 1.1.3 for driving the amplitude modulation box 1.1.2;

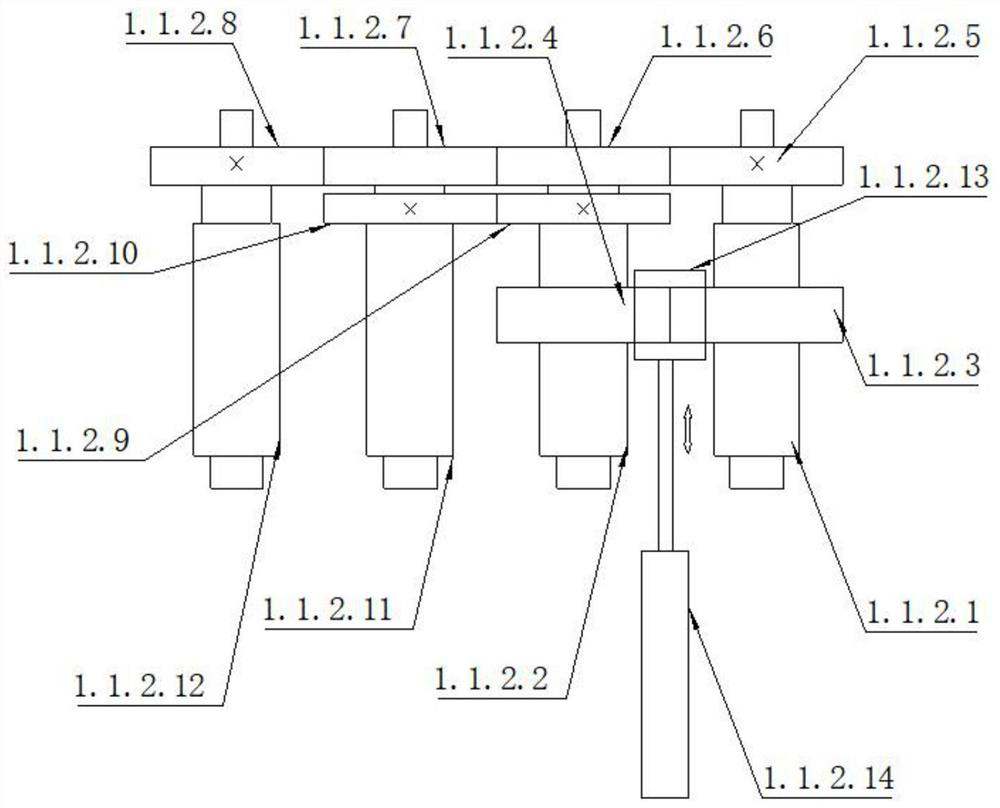

[0036] Described amplitude modulation box 1.1.2 comprises the amplitude modulation box body and the amplitude modulation system installed in the amplitude modulation box body, and the amplitude modulation drive oil cylinder 1.1.2.14 (see image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com