Coiled plate leading device

A technology of coiling and uncoiling, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of affecting normal work, high labor intensity, low work efficiency, etc., and achieves good uncoiling effect, simple structure, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

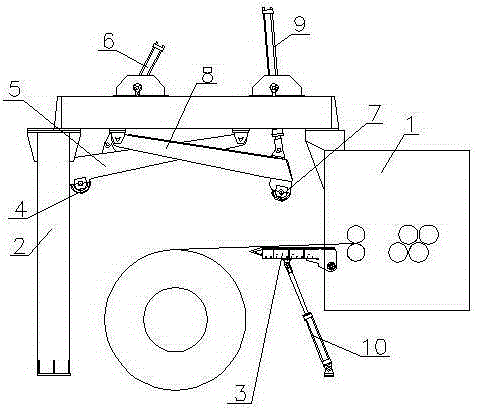

[0013] A coiling guide device, comprising a straightening device 1, the feed end of the straightening device 1 is provided with a frame 2, and the frame 2 is provided with an unwinding device and a rolling device, and the straightening device The feed end of 1 is provided with lead material pallet 3, and described material lead pallet 3 is positioned at frame 2 below, and described unwinding device is positioned at the front end of rolling device; Described unwinding device comprises unwinding roller 4, unwinding bar 5 and an unwinding swing cylinder 6, the tail end of the unwinding rod 5 is hingedly connected to the rear side of the lower end of the frame 2, the unwinding roller 4 is installed on the front end of the unwinding rod 5, and the piston of the unwinding swing cylinder 6 The front end of the rod is hingedly connected to the front end of the unwinding rod 5, and the unwinding swing cylinder 6 is hingedly connected to the front side of the upper end of the frame 2; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com