Stage style alloy female die core

A step-type, negative mold technology, applied to metal processing equipment, bolts, connecting components, etc., can solve the problems of poor head size consistency of countersunk parts, easily out-of-tolerance mold orifice size, and poor consistency of part rod diameters, etc. , to achieve the effect of simple structure, ensuring consistency and improving mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation, structure, features and functions of the step-type alloy die core according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

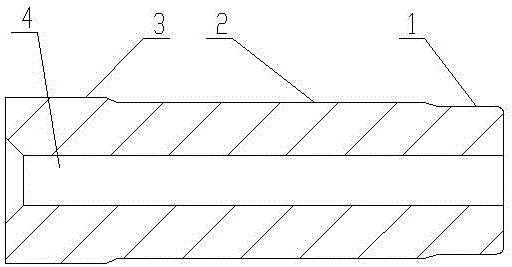

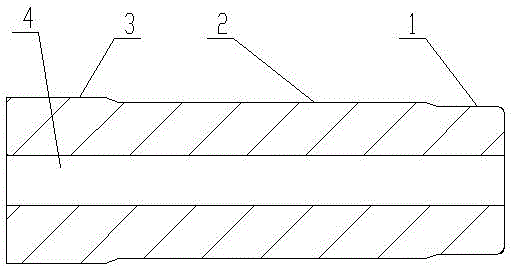

[0018] see Figure 1 to Figure 2 , the stepped alloy die core of the present invention includes a first step 1, a second step 2 and a third step 3, wherein: the first step 1, the second step 2 and the third step 3 form a die core, and the middle A cavity 4 is provided, and the outer diameters of the first step 1 , the second step 2 and the third step 3 increase sequentially. The cavity 4 is a straight hole, a countersunk angle hole or a stepped hole. The die core is made of alloy.

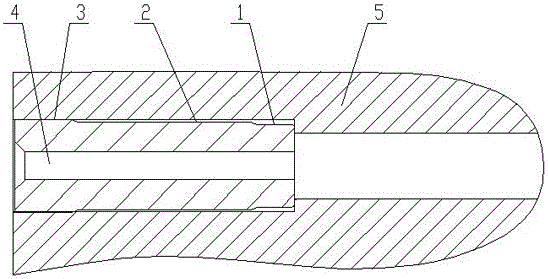

[0019] see image 3 , press the die core and the die sleeve 5 to form the die, and the outer diameters of the first step 1, the second step 2 and the third step 3 increase sequentially, that is, the size tolerance and requirements of the pressing holes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com