A functional protection material for continuous casting mold for high-oxygen enamel steel

A continuous casting crystallizer and protective material technology, applied in the field of metallurgical auxiliary materials, can solve the problems of various oxide inclusions, increase steel brittleness, etc., and achieve the effect of strong wear resistance and good anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the special continuous casting crystallizer functional protection material for high-oxygen enamel steel of the present invention comprises the following steps:

[0045] Step S1: Weigh the above-mentioned raw materials for weighing and batching, put them into a mixer and mix for 40-50 minutes; then add them to a stirring mill, mix with water, grind, and sieve to obtain a slurry with a particle size of ≤1mm;

[0046] Step S2: The slurry is pumped through the slurry pipeline by the ceramic plunger slurry to the prilling tower for atomization and drying, and the slurry changes from liquid to solid to form hollow particles;

[0047] Step S3: Sieve the hollow particles to obtain qualified material, cool and pack.

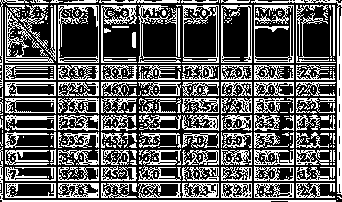

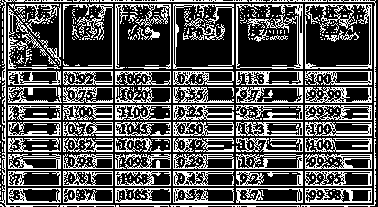

[0048] The chemical composition of the premelt used in the present invention and its weight percentage are: SiO 2 25.0~35.0%, CaO35.0~46.0%, Al 2 o 3 2.0~7.0%, R 2 O4.0~15.0%, F ~ 2.0~8.0%, MgO2.0~6.0%, of which R 2 O=K 2 O+Na 2 O+...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com