Insert casting forming method of single-armed pipe

An inlaid casting and one-armed technology, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of sand core sintering, cracking, and the inner wall of the oil pipe is not smooth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

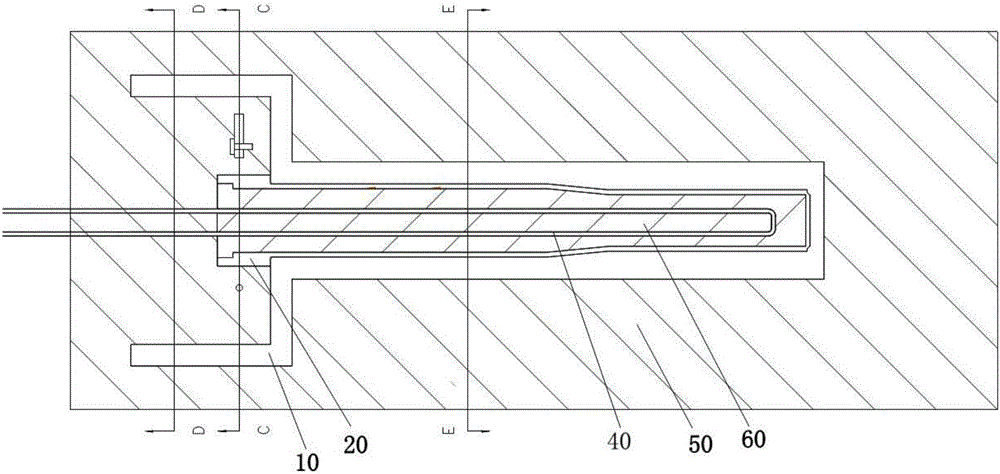

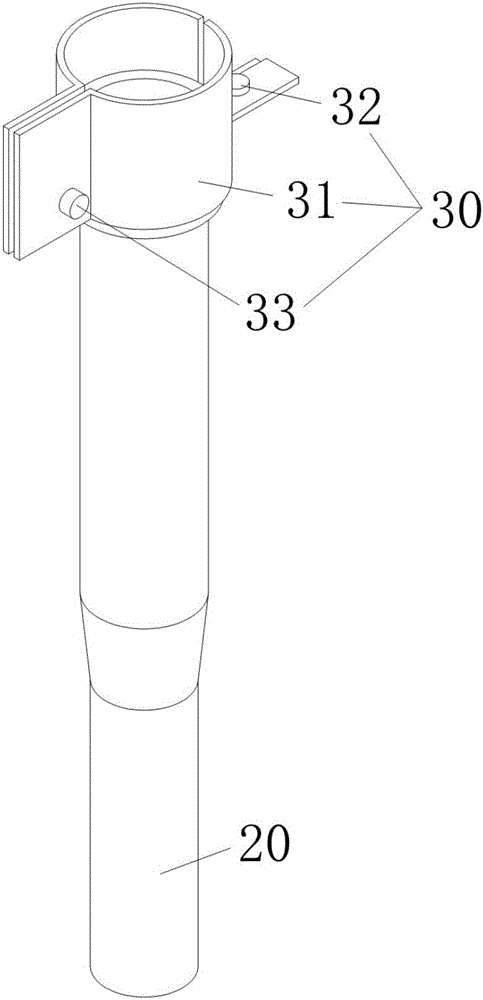

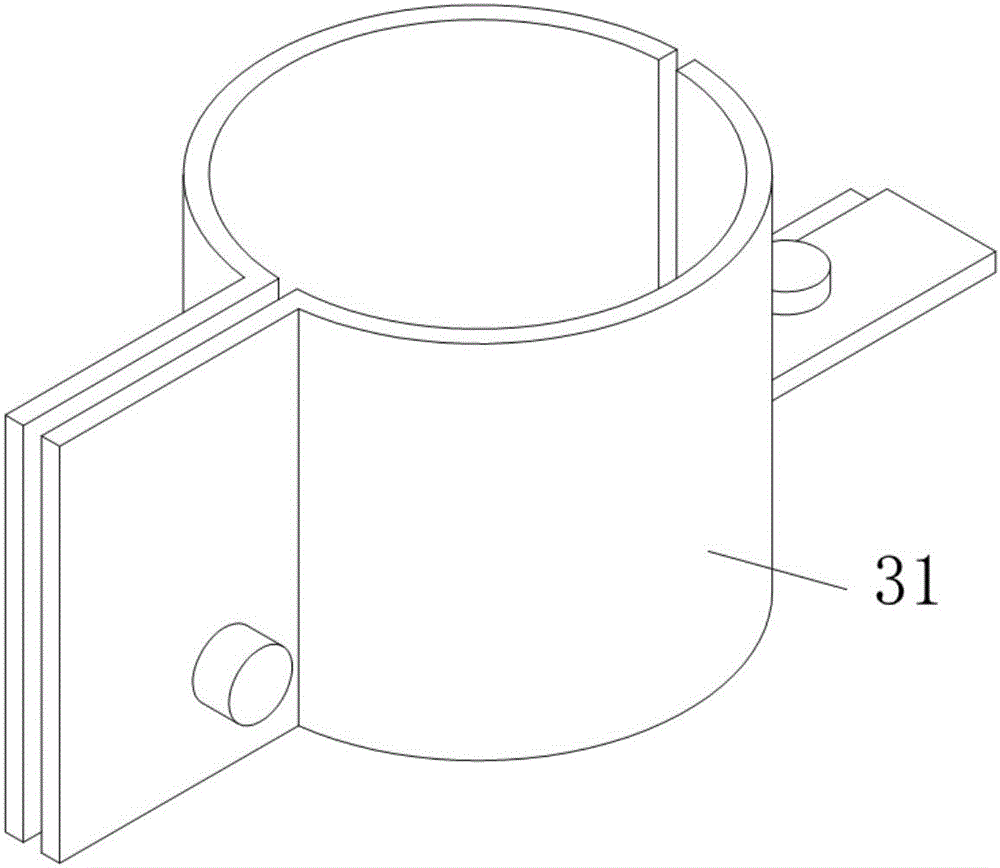

[0027] see Figure 1 to Figure 9 , the embodiment of the present invention provides a one-arm pipe insert casting molding method, including the following steps;

[0028] Prepare the casting tube: select a casting tube 20, the casting tube 20 is a slender hollow metal tube, the material of the casting tube 20 is the same as that of the casting body 10, the mouth of one end of the casting tube is sealed, and the other end is The orifice is open;

[0029] The cast-in method is simple in process. In a specific embodiment, the single-arm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com