Casting production line transition system

An assembly line and system connection technology, applied in foundry equipment, manufacturing tools, equipment for handling casting molds, etc., can solve the problems of complex positioning system, inconvenient maintenance, complex system structure, etc., to simplify the mechanical structure, reduce the failure rate, The effect of accurate car positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

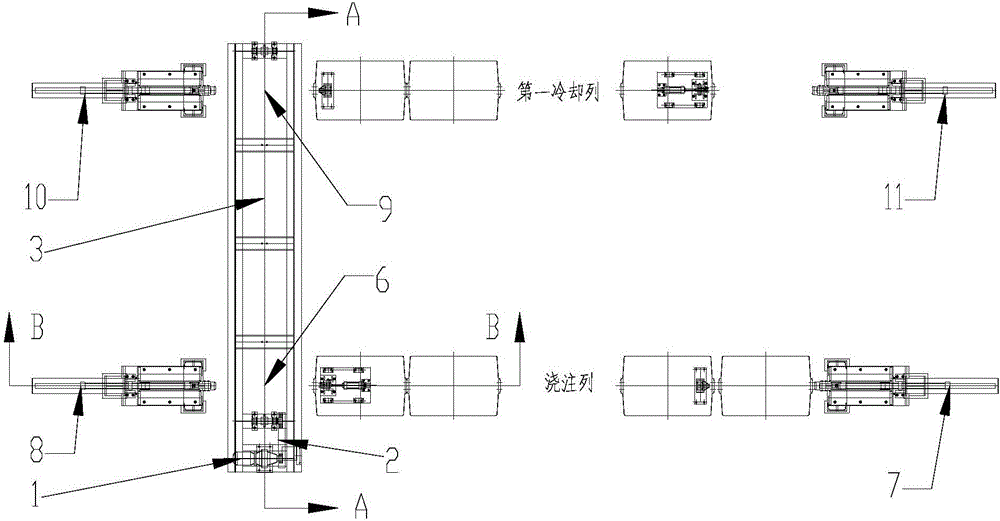

[0027] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

[0028] In this embodiment, the casting cooling column transition system is taken as an example to further explain the technical solution of the present invention. There are four transition systems in the entire casting cooling line, and the four systems have the same principle and structure.

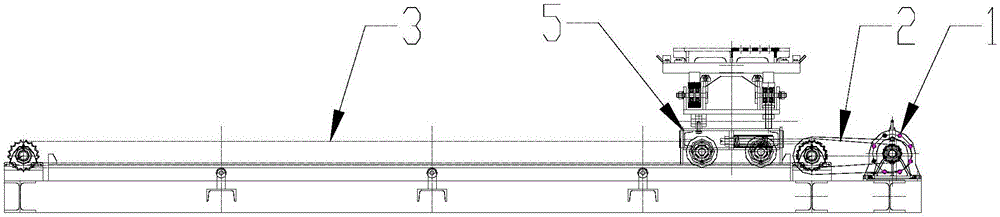

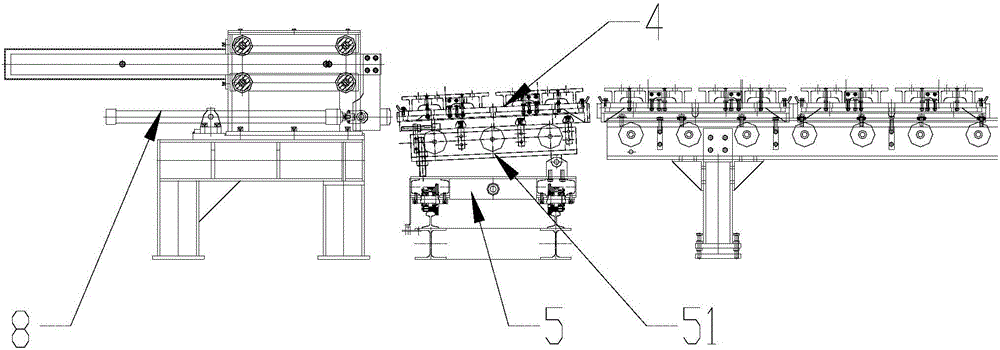

[0029] In the system, the variable frequency motor 1 drives the primary drive chain 2, the primary drive chain 2 drives the secondary drive chain 3, and the secondary drive chain 3 pulls the transfer trolley 5 that is not equipped with the foundry bottom plate 4 to the origin 6. Under the cooperation of the first push cylinder 7 and the first buffer cylinder 8, the castor bottom plate 4 enters the transfer trolley 5 from the pouring row. Since the platform 51 carrying the caster's base plate 4 is inclined, the caster's base plate 4 slides down to the lowest posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com