Preparation method of high-quality spherical nickel powder

A high-quality, nickel powder technology, applied in the field of preparation of high-quality spherical nickel powder, can solve the problems of poor powder shape and poor deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

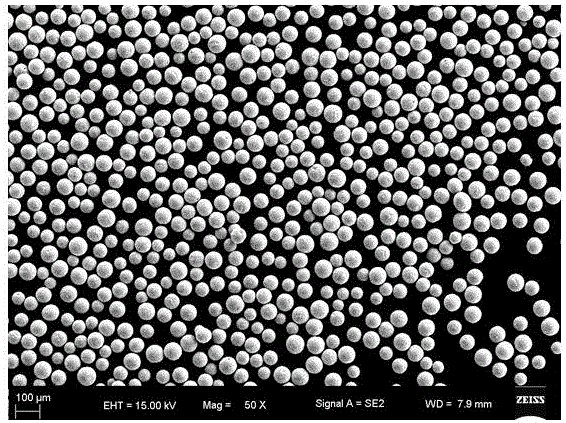

Image

Examples

Embodiment 1

[0020] A preparation method of high-quality spherical nickel powder, comprising the following steps:

[0021] 1) According to the ingredients of pure nickel, nickel rods are smelted by vacuum induction melting and electroslag remelting;

[0022] 2) Finish turning the smelted nickel rod into an electric shock rod. The diameter of the processed electrode rod is 55mm, the length is 500mm, the roundness deviation is 0.03mm, the straightness deviation is 0.045mm / 450mm, and the roughness is 1.22μm;

[0023] 3) Load the electrode rod into the reaction chamber, and evacuate the reaction chamber to 2×10 -3 Pa, fill the reaction chamber with helium, so that the pressure in the chamber is 0.13MPa;

[0024] 4) The power of the plasma gun of PREP powder making equipment is 200kW. The plasma torch contains tungsten cathode and copper anode. The electrode rod is not used as an electrode. The plasma heats the end of the electrode rod. Melting, the atomized droplets are thrown out from the e...

Embodiment 2

[0029] A preparation method of high-quality spherical nickel powder, comprising the following steps:

[0030] 1) According to the ingredients of pure nickel, nickel rods are smelted by vacuum induction melting and electroslag remelting;

[0031] 2) Finish turning the smelted nickel rod into an electric shock rod. The diameter of the processed electrode rod is 75mm, the length is 650mm, the roundness deviation is 0.025mm, the straightness deviation is 0.025mm / 650mm, and the roughness is 0.58μm;

[0032] 3) Load the electrode rod into the reaction chamber, and evacuate the reaction chamber to 7×10 -3 Pa, fill the reaction chamber with helium, so that the pressure in the chamber is 0.14MPa;

[0033] 4) The power of the plasma gun of PREP powder making equipment is 100kW. The plasma torch contains tungsten cathode and copper anode. The electrode rod is not used as an electrode. The plasma heats the end of the electrode rod. Melting, the atomized droplets are thrown out from the ...

Embodiment 3

[0038] A preparation method of high-quality spherical nickel powder, comprising the following steps:

[0039] 1) According to the ingredients of pure nickel, nickel rods are smelted by vacuum induction melting and electroslag remelting;

[0040] 2) Finish turning the smelted nickel rod into an electric shock rod. The diameter of the processed electrode rod is 65mm, the length is 800mm, the roundness deviation is 0.06mm, the straightness deviation is 0.04mm / 800mm, and the roughness is 1.23μm;

[0041] 3) Load the electrode rod into the reaction chamber, and evacuate the reaction chamber to 3×10 -3 Pa, fill the reaction chamber with helium, so that the pressure in the chamber is 0.14MPa;

[0042] 4) The power of the plasma gun of PREP powder making equipment is 300kW. The plasma torch contains tungsten cathode and copper anode. The electrode rod is not used as an electrode. The plasma heats the end of the electrode rod. Melting, the atomized droplets are thrown out from the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap