A base mechanism of a spot welding machine

A spot welding machine and spot welding technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as difficult height adjustment, affecting work efficiency, and easy wear of the lower electrode, so as to save debugging fixtures Time, improve production efficiency, welding firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

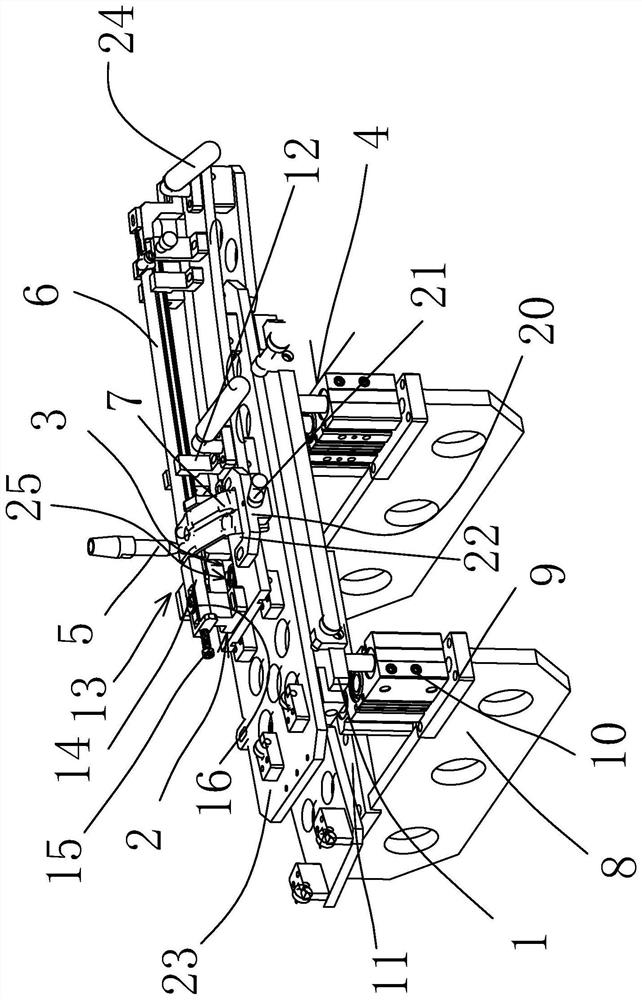

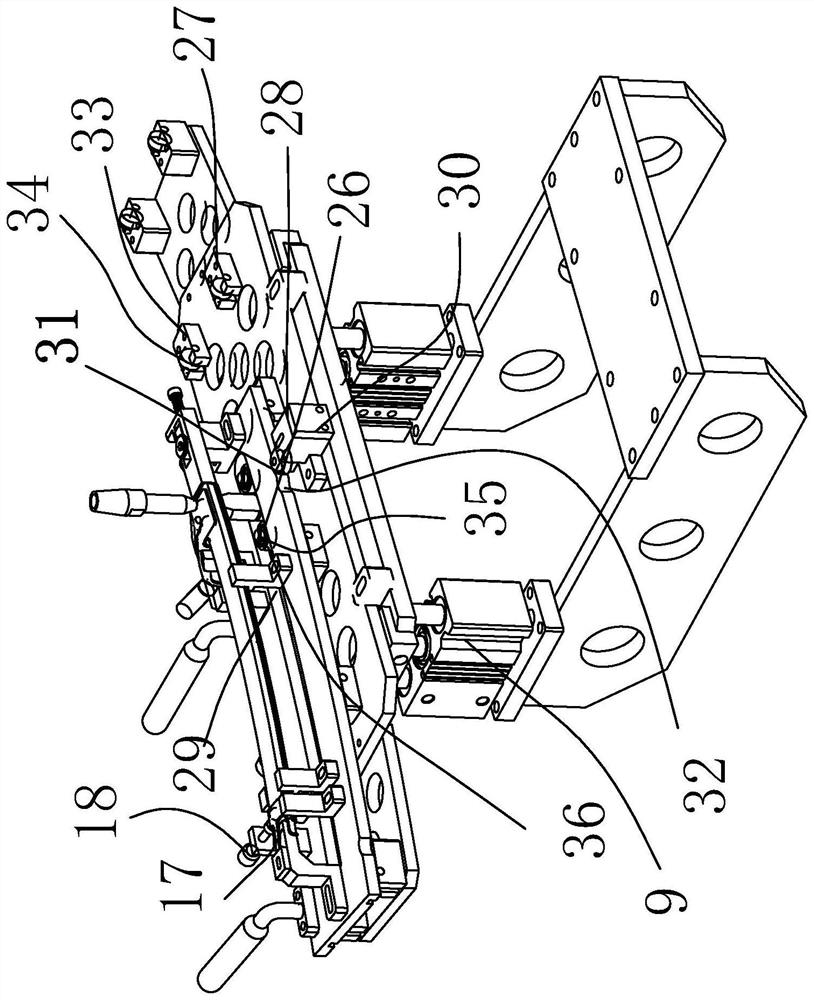

[0022] In the figure, bottom plate 1; product fixing jig part 2; curved surface moving part 3; floating part 4; electrode head 5; automobile guide rail 6; bracket 7; fixed plate 8; floating cylinder 9; cylinder fixed plate 10; nylon block 11 ; fixed block 12; end limit component 13; end limit block 14; adjustment screw 15; locking piece 16; guide rail fork limit block 17; Bracket limit block 20; Bracket lock 21; Limit port 22; Mobile main board 23; Operating handle 24; Mobile auxiliary component 25; Middle rolling component 26; End rolling component 27; 29; side fixing block 30; side roller 31; inclined groove top mouth 32; end fixing block 33; end roller 34; middle roller 35; middle roller 36.

[0023] Such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com