Wedge block parallel type positioning method and device

A positioning device and wedge-shaped block technology, applied in the field of machinery, can solve the problems of insufficient stability of heavy machinery positioning, and achieve the effects of easy maintenance, fast and accurate positioning, and a simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings.

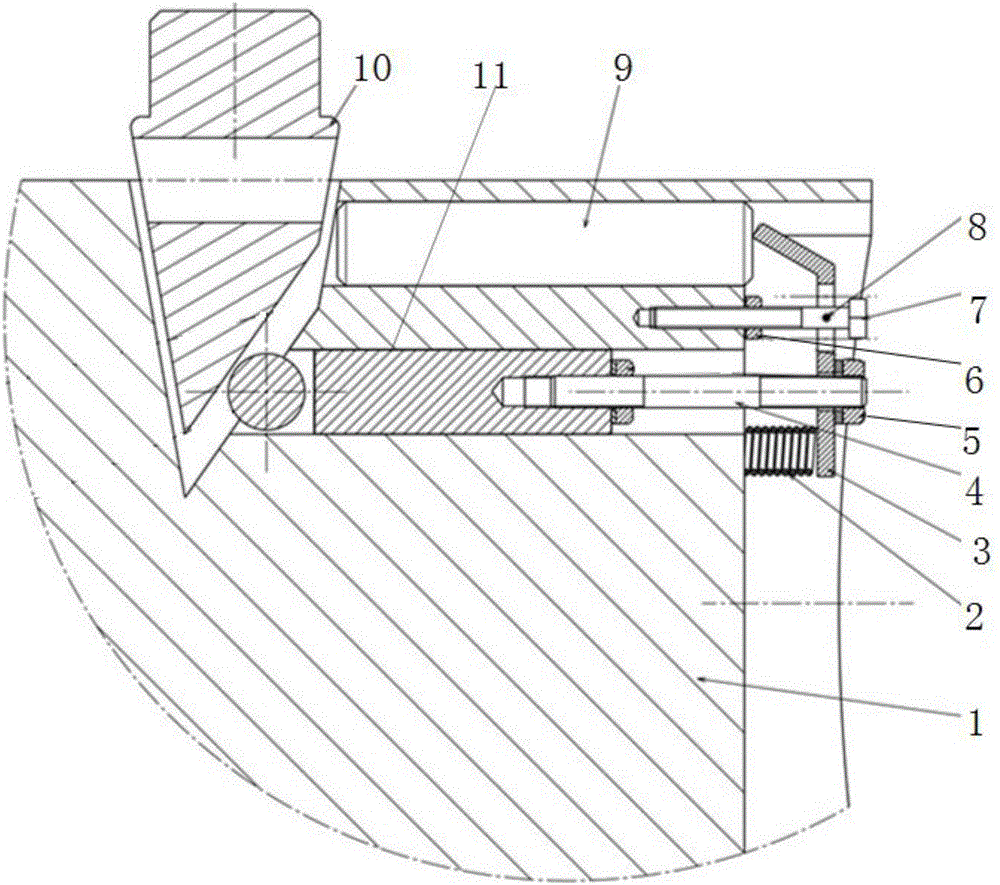

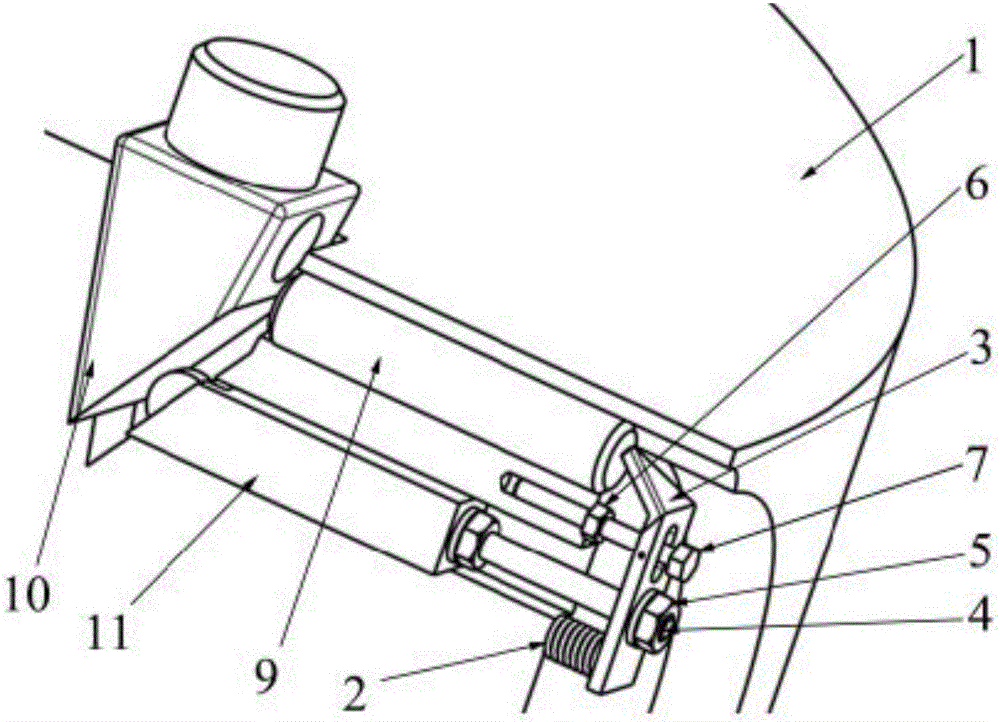

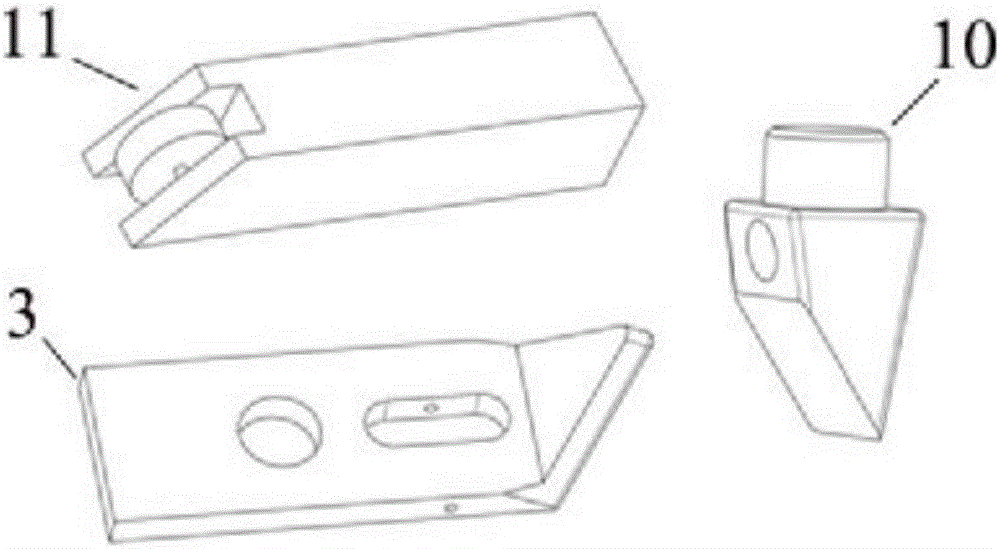

[0016] like figure 1 The wedge block parallel positioning device shown includes a base 1, a spring 2, a rotating block 3, a stud 4, two No. 1 nuts 5, No. 2 nuts 6, bolts 7, rotating pins 8, positioning Pin 9, wedge block 10 and slider 11.

[0017] The base 1 is fixed, and the base 1 is provided with an inner surface adapted to the wedge block 10, a slide block channel adapted to the slider 11, and a positioning pin channel adapted to the positioning pin 9, and the wedge block 10 is small. The end is on the bottom and the big end is on the top, which can reciprocate up and down. The inner surface is aligned with the wedge block 10 and the diameter gradually becomes smaller from the outside to the inside. The slider channel and the positioning pin channel are both horizontal channels. The slider 11 and the positioning pin 9 Can move freely in respective channel; Descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com