Pipe fitting machining structure

A technology of pipe fittings and adjusting rods, which is applied to metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of slow manual grinding speed, difficult to guarantee quality, uneven quality, etc., so as to improve the efficiency and quality of grinding work. , the effect of eliminating attachments and protrusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

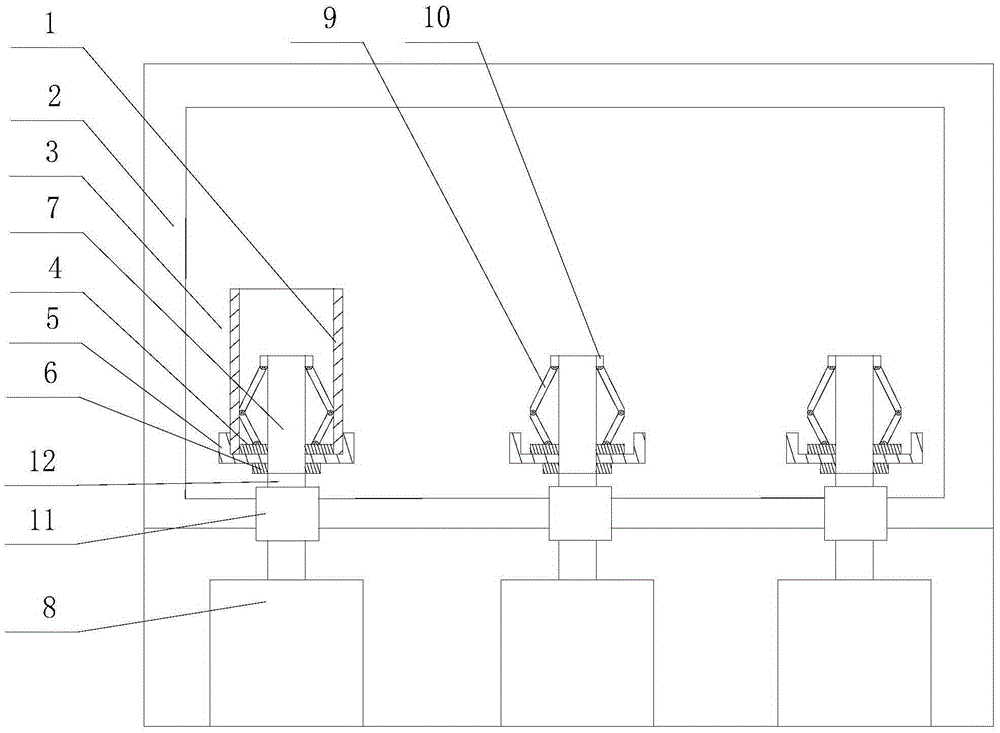

[0019] Such as figure 1 As shown, the present embodiment includes a frame 2, a plurality of motors 8 are installed below the frame 2, and a grinding paper 3 is vertically installed above the frame 2 along the axial direction of the output end of the motor 8. An adjustment rod 7 is connected to the output end of the motor 8, and the adjustment rod 7 extends upwards to the middle part of the grinding paper 3, and the middle part of the adjustment rod 7 is also provided with a deck 5 for fixing the pipe fitting 1. 5 The upper and lower ends are respectively provided with an upper fastening block 4 and a lower fastening block 6, and the outer peripheral wall of the adjustment rod 7 is provided with external threads, and the upper fastening block 4 and the lower fastening block 6 are respectively connected with The adjustment rod 7 is threaded; it also includes an adjustment nut 10, which is threaded on the outer wall of the upper end of the adjustment rod 7, and the adjustment nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com