Sand belt washing equipment

A technology of abrasive belts and equipment, which is applied in the field of cleaning equipment for woodworking abrasive belts, can solve the problems of inability to reduce costs, environmental pollution of waste abrasive belts, and increase costs and expenses, and achieve the effect of convenient maintenance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution will be described in detail below in conjunction with specific embodiments.

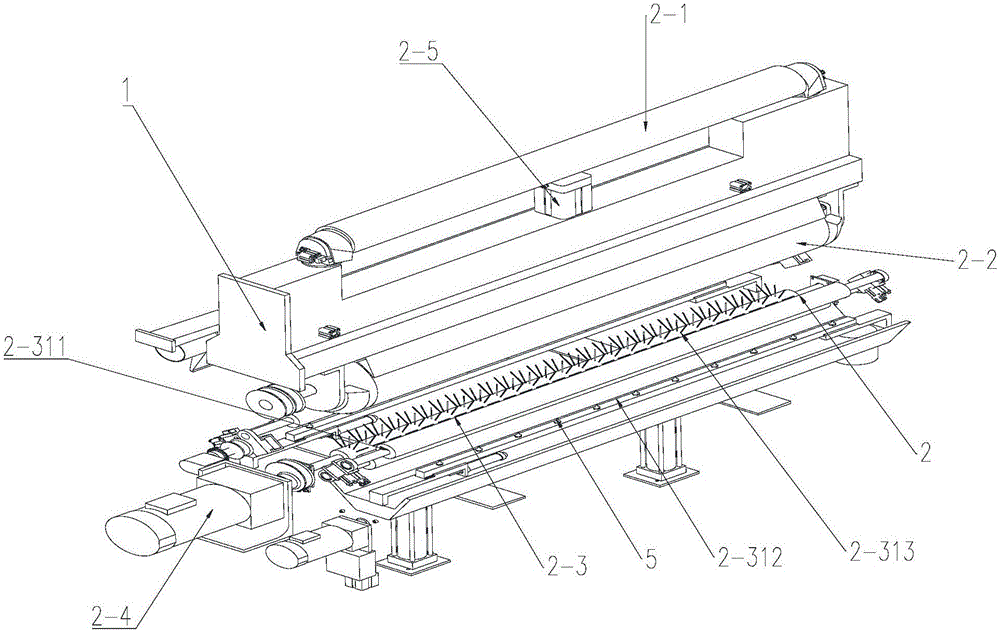

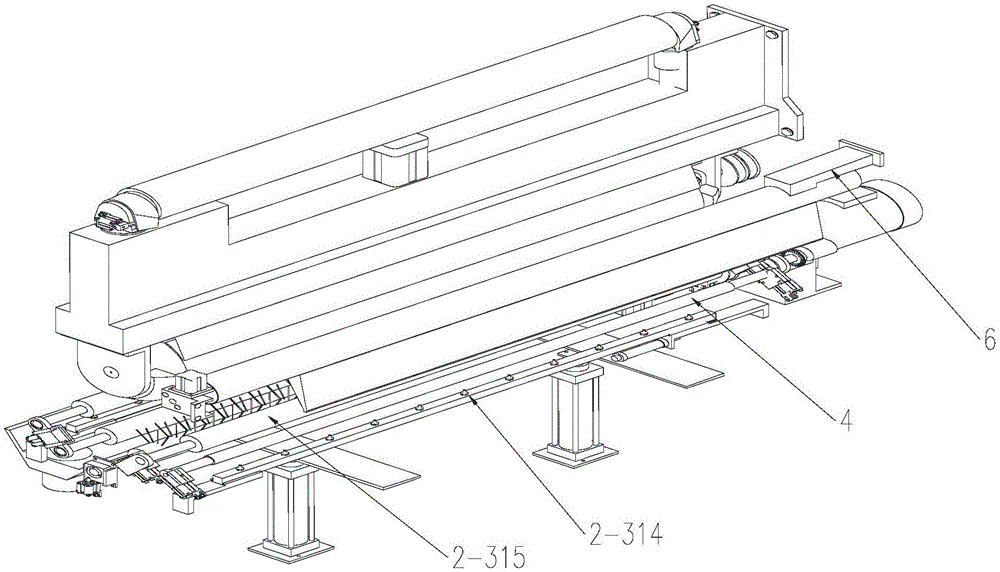

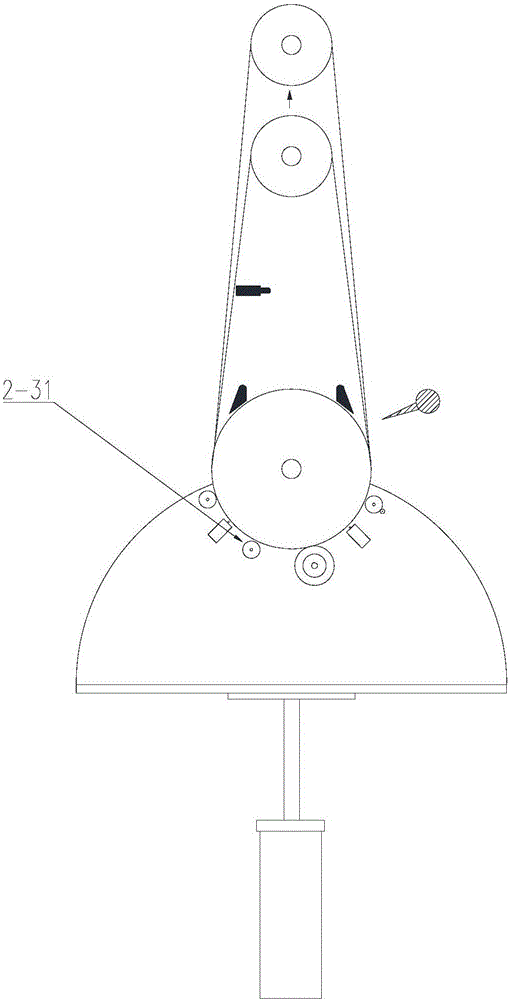

[0025] Such as Figure 1-Figure 5 Shown, the present invention is a kind of abrasive belt washing equipment, and it comprises a frame 1, is provided with the suspension shaft of placing abrasive belt on the frame; The rollers 2-1, 2-2, the roller brush cleaning device 2-3 and the power device 2-4 for driving the various components are composed. An abrasive belt tensioning device 2-5 is arranged between the upper and lower rubber rollers, and the roller brush cleaning The device 2-3 is provided with a roller brush cleaning core combination 2-31 matched with the lower rubber roller; the roller brush cleaning core combination is distributed along the surface of the lower rubber roller, including sequentially along the circumferential direction of the lower rubber roller 2-2. Distributed sponge roller shaft device 2-311, detergent spray shaft 2-312 equipped with liquid medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com