Wiring robot of automatic wiring machine

A wiring machine and robot technology, applied in the direction of manipulators, cable laying equipment, manufacturing tools, etc., can solve the problems of inflexible movement and insufficient freedom, and achieve the effects of strong line control, simplified structure, and flexible wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, introduce technical scheme of the present invention in detail:

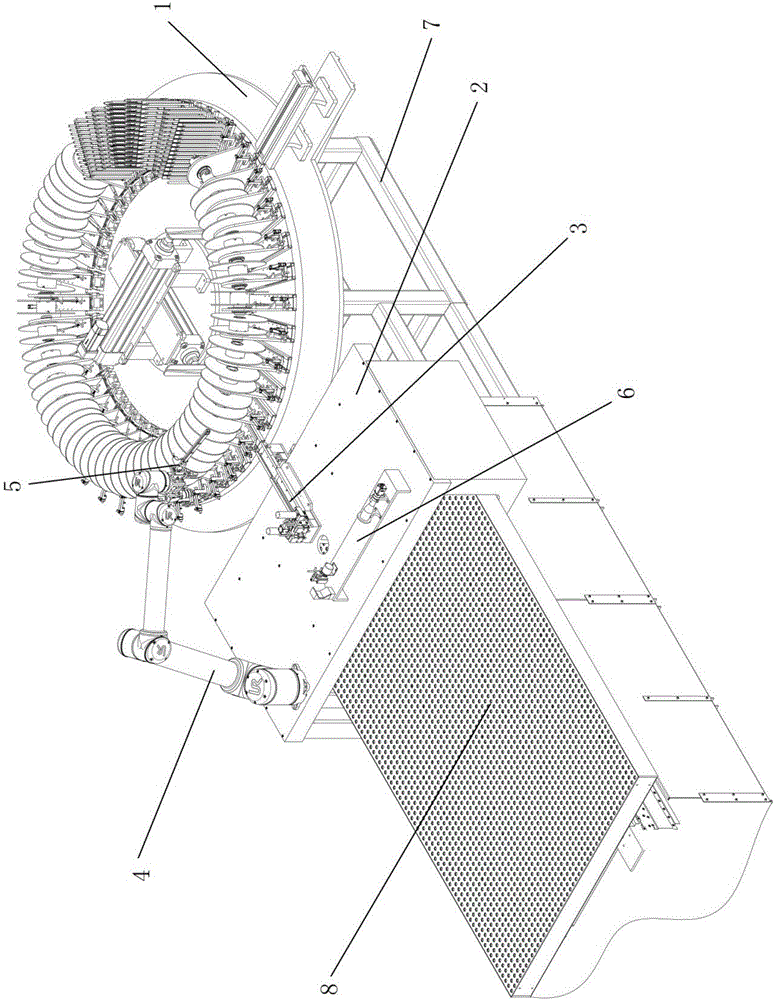

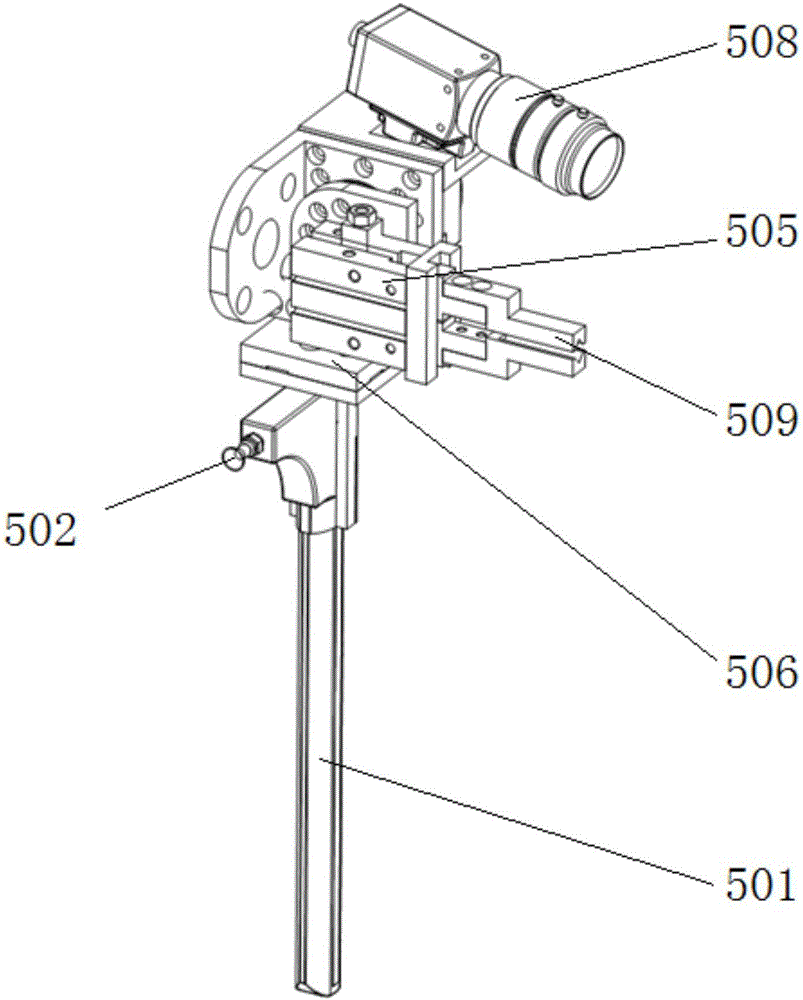

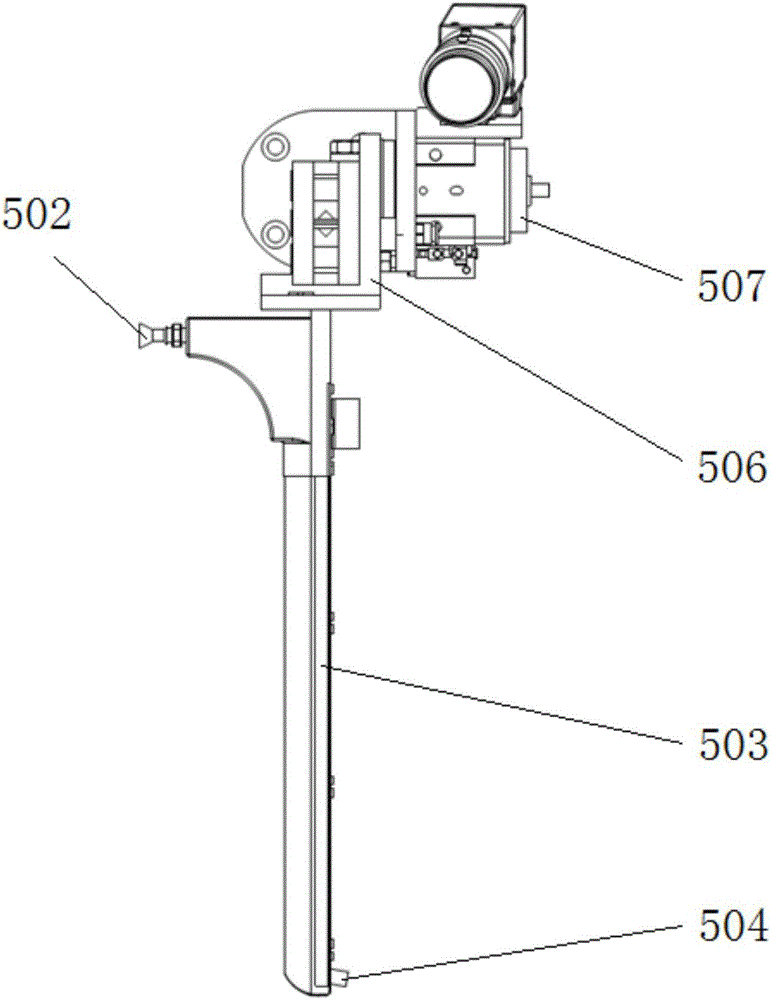

[0027] Such as figure 1 As shown, an aircraft wiring harness automatic wiring machine includes a material warehouse 1, a slide table 2, an automatic wire feeder 3, an automatic wiring machine wiring robot 4, an optical line number recognition and meter counter 6, a connecting frame 7, and a workbench 8 , PC. The material warehouse 1 is installed on the connecting frame 7, the working table 8 is installed on the front end of the connecting frame 7, the sliding table 2 is slidably connected on the working table 8, and it can slide along the slide rail of the working table 8 on the working table 8, and the automatic wiring machine The wiring robot 4 is installed on the slide table 2. The automatic wiring machine The wiring robot 4 is composed of a six-degree-of-freedom mechanical arm and a multi-functional manipulator 5. The automatic wire feeder 3 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com