Air-pressure-assisted background plate forming machine

A background board and molding machine technology, applied in the field of background boards, can solve the problems of cumbersome manual compression molding process, unstable product quality, and high production cost, and achieve the effects of consistent effect, stable product quality, and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

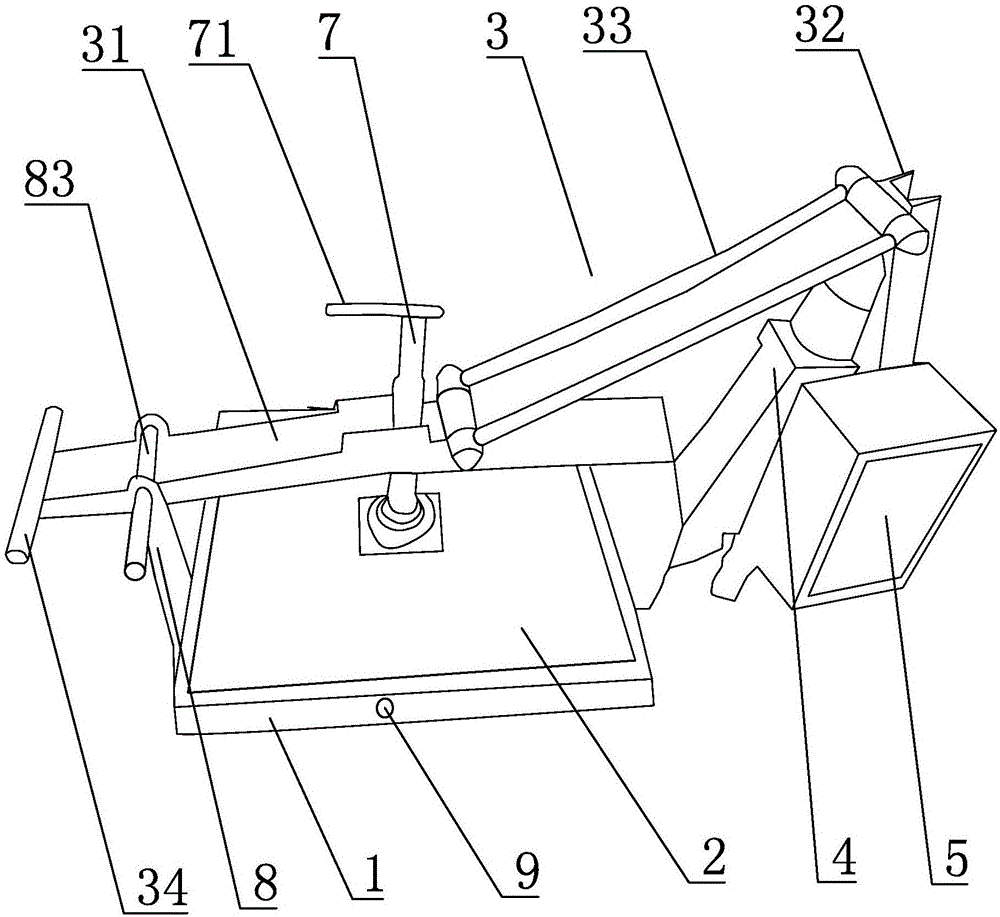

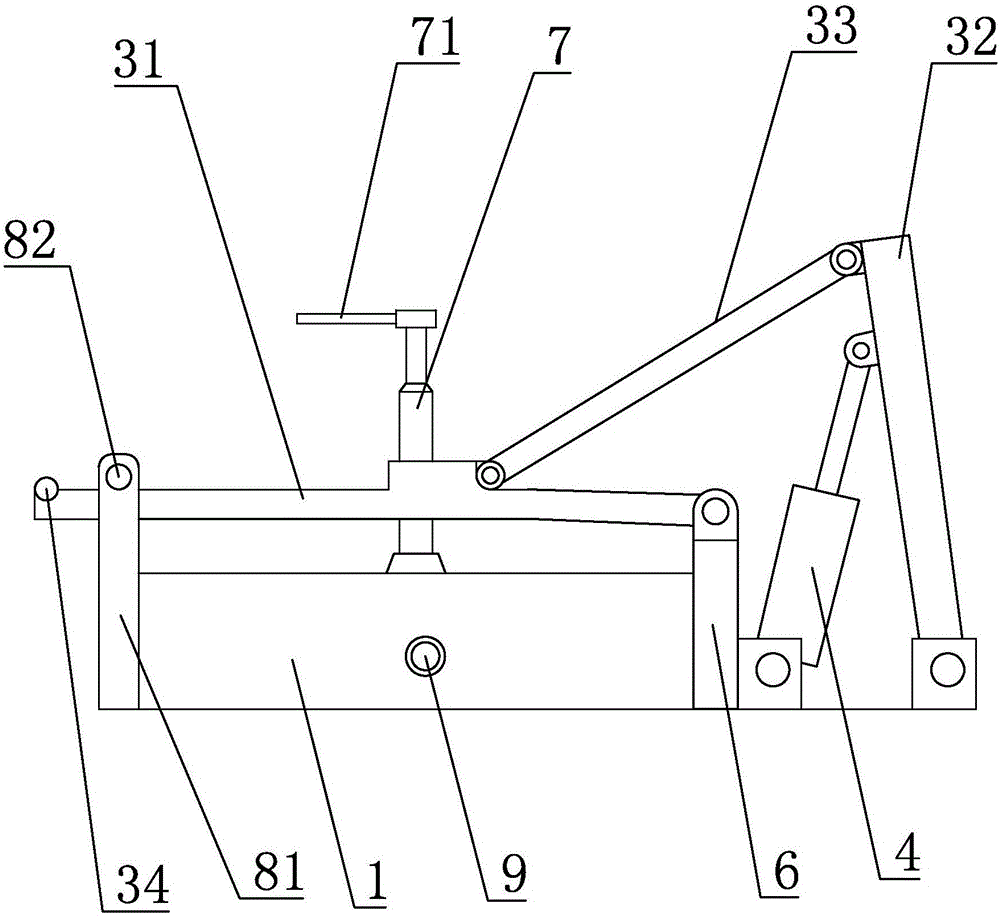

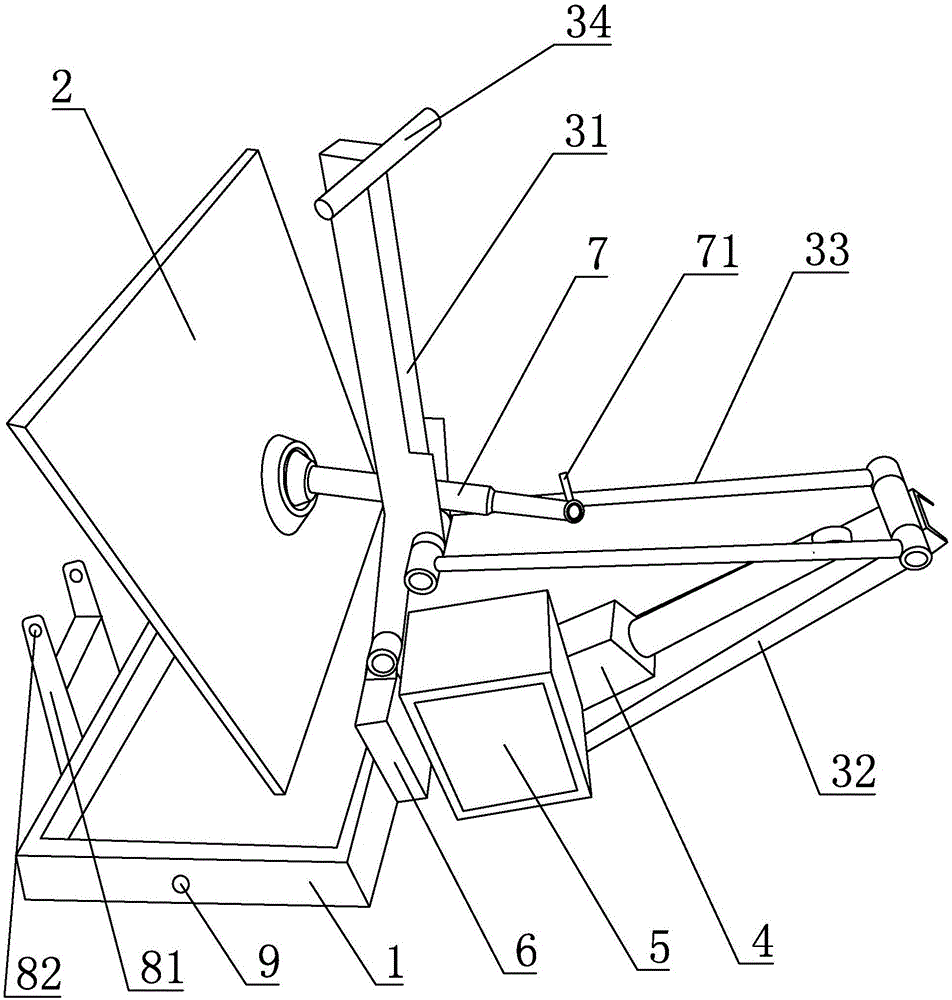

[0020] refer to figure 1 , a kind of air-assisted background plate molding machine, comprises molding frame 1, and molding frame 1 is a square frame, is provided with the square die cover plate 2 that matches with its inner cavity on it, during processing, injects resin in molding frame 1 The material is smoothed, and then the mold is placed on it. The lower surface of the mold has a prefabricated texture shape. A cushion layer is placed on the mold, and then the mold cover plate 2 is placed, and pressed with a heavy object. Wait for the resin material to solidify, and separate the mold You can get the background board. Because of the cumbersome manual compression molding process, unstable product quality, more manpower, high production cost and low efficiency, the present invention strives to improve and optimize it to overcome these deficiencies.

[0021] refer to Figures 1 to 3 , the press mold cover plate 2 is provided with a compression link mechanism 3, the press mold...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap