Road-railer two side clamping system

A technology for road-rail dual-purpose vehicles and locking pins, which is applied to rail and road dual-purpose vehicles, motor vehicles, transportation and packaging, etc. It can solve the problems of cumbersome connection steps and high precision, and achieve low precision requirements and cumbersome optimization. Action, effect of lowering altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

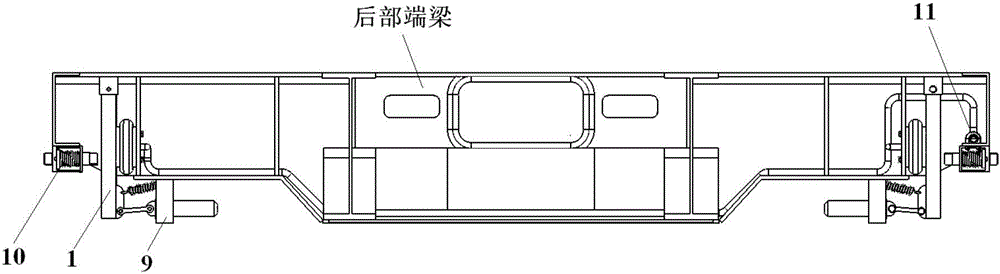

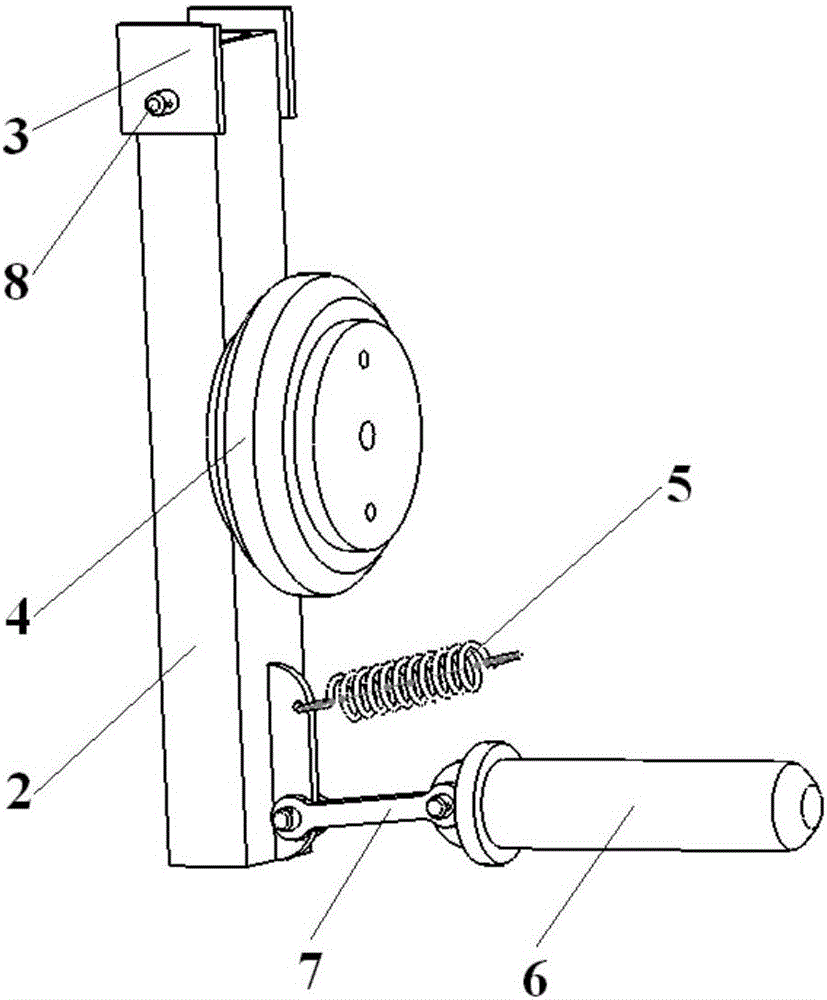

[0031] According to the above technical solution, as shown in Figure 1, the present embodiment provides a locking device 1, the locking device has a rotating shaft 2 as the main body of the rotating body, and an air spring 4, a telescopic mechanism 5, and a connecting shaft 7 are connected to the locking device. The locking pin 6 and the retractable mechanism 5 can use springs, which are simple and easy to obtain. The round pin 8 is connected to the rotating shaft 2 and the card seat 3. The card seat 3 is welded on the rear end beam of the vehicle, and the other end of the air spring 4 is passed through the bolt. Connected to the web plate of the rear end beam, the locking pin 6 is connected on the rear end beam through a guide sleeve 9, and holes on the guide sleeve 9 are connected to the rotating shaft 2 through the telescopic mechanism 5 .

[0032] The working principle of locking device 1 is:

[0033] When the compressed air inflates the air springs 4 of the two locking de...

Embodiment 2

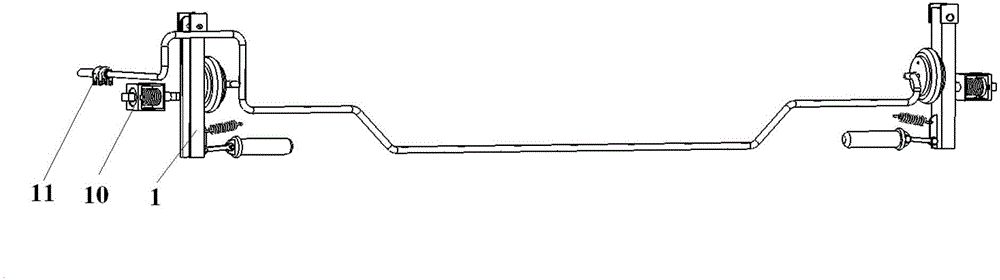

[0038] Comply with the above technical scheme, as shown in Figure 1 to Figure 5 As shown, this embodiment provides a clamping system on both sides of a road-rail dual-purpose vehicle, which is a left-right symmetrical structural arrangement of the vehicle body, including a locking device 1, an anti-loosening device 10 and an air circuit device 11;

[0039] The anti-off device 10 includes a box body 12 with an open front and a handle 13. A horizontal positioning bar 14 is processed inside the left side of the box body 12. The handle 13 passes through both sides of the box body 12 and is positioned at the handle in the box body 12. Positioning seat 15 is installed on 13, and positioning block 16 is processed at the front end of positioning seat 15, and positioning block 16 can be embedded in the positioning bar 14 when horizontal direction, and one end of spring 17 is installed on the described positioning seat 15, the other end of spring 17 One end is fixed on the handle 13, a...

Embodiment 3

[0043]This embodiment provides a clamping system connecting the road-rail vehicle and the special railway running device, so that the road-rail vehicle can travel on the railway. The specific working process is as follows: first, connect the road-rail dual-purpose vehicle to the automobile tractor, open the valve 21 of the air circuit device 11 after connecting the air source, the air circuit device 11 is connected and supply air to the air spring 4 of the locking device 1, and the air The spring 4 is inflated to push away the rotating shaft 2, and the rotating shaft 2 pulls the connecting shaft 7, the locking shaft 6 and the telescopic mechanism 5 outward. Then, the tractor drives the public-rail vehicle to pour backward into the railway special running device 23 (the railway bogie is omitted), after pouring into the designated position, close the valve 21 of the air circuit device 11, so that the valve interface on the air spring 4 side Connected with the atmosphere to exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com