Complete decoupling type braking system with fail-safe function and control method

A completely decoupling and fail-safe technology, applied in brake safety systems, brakes, brake transmissions, etc., can solve problems such as increasing the complexity of the mechanical structure, and achieve simple and easy technical means, low noise and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

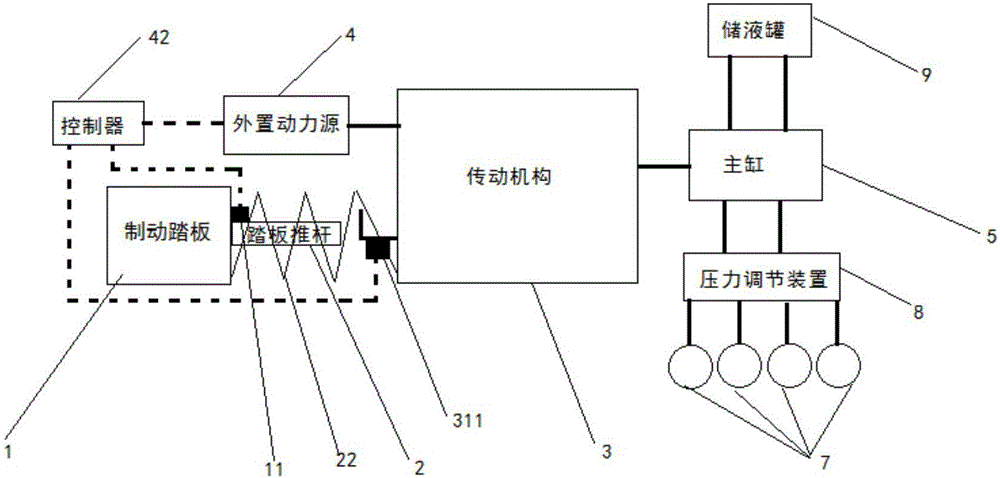

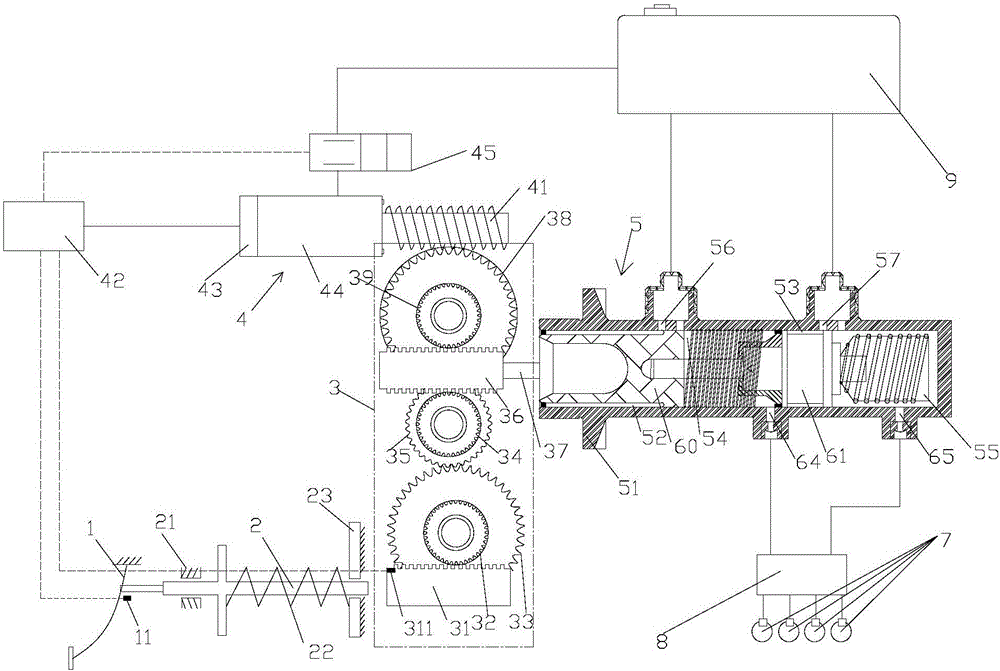

[0034] Such as Figures 1 to 4 shown. The invention discloses a complete decoupling brake system with failure protection, which includes a hydraulic tank 9, a master cylinder 5, a hydraulic adjustment device 8 and a wheel cylinder 7; the two outlets of the hydraulic tank 9 are respectively connected to the master cylinder by pipelines The two oil supply holes 56, 57 of 5, and the two liquid discharge holes 64, 65 of the master cylinder 5 communicate with the wheel cylinder 7 through the hydraulic adjustment device 8 respectively;

[0035] The fully decoupled braking system with fail-safe also includes a brake pedal 1, a brake push rod 2, a transmission mechanism 3 and an external power source 4;

[0036] The external power source 4 is used to provide the transmission mechanism 3 with rotational torque;

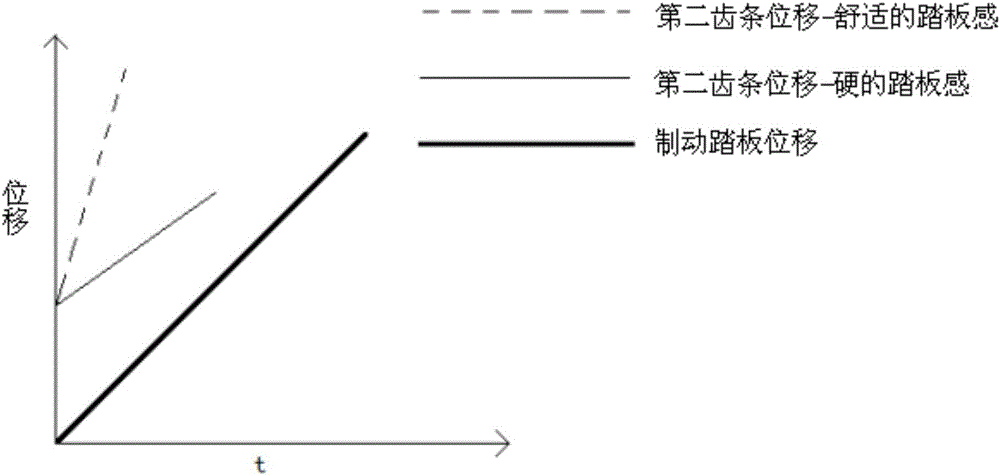

[0037] The brake pedal 1 is movably connected to the brake push rod 2, and the end of the brake push rod 2 close to the transmission mechanism 3 is provided with a baffle pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com