Tying equipment for carton production

A technology of equipment and carton, which is applied in the directions of bundling materials, parts of bundling machinery, and packaging of paper products, etc., can solve the problems of uneven bundling force, large workload of workers, time-consuming and laborious, etc. Even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

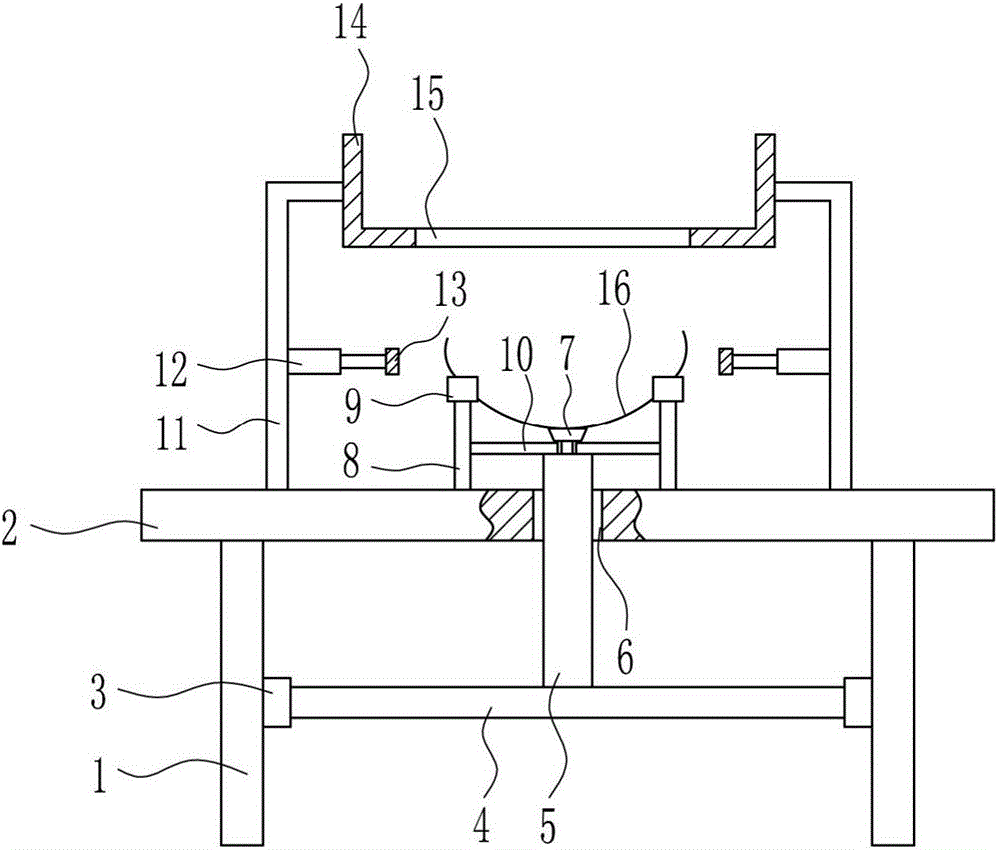

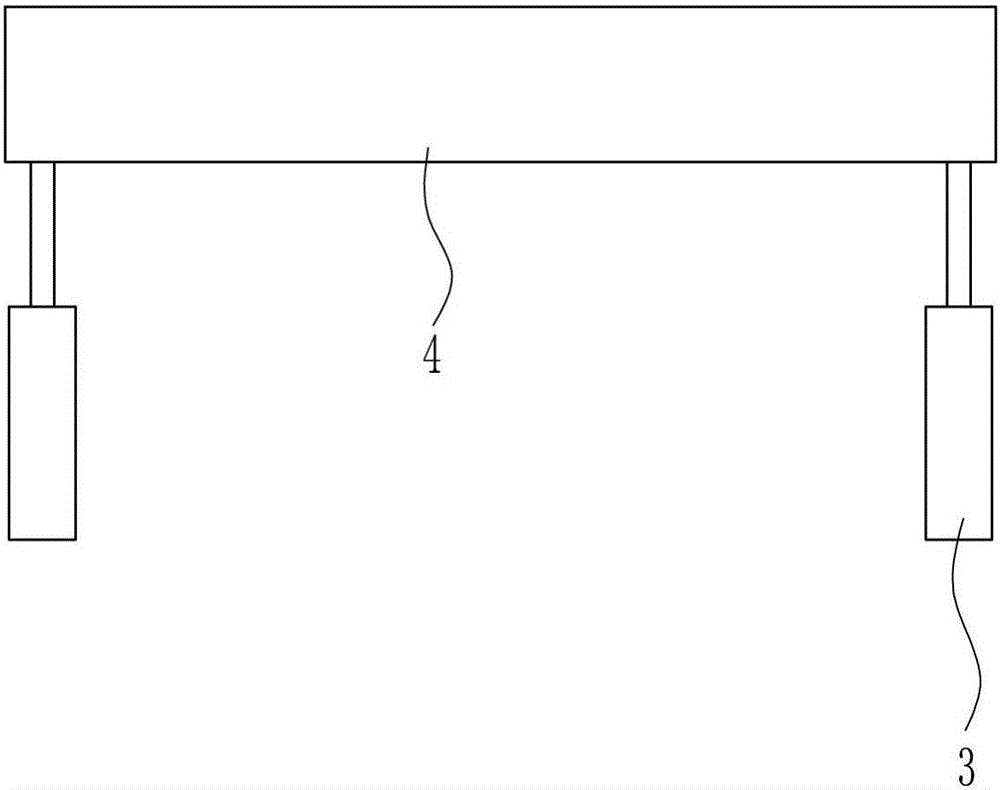

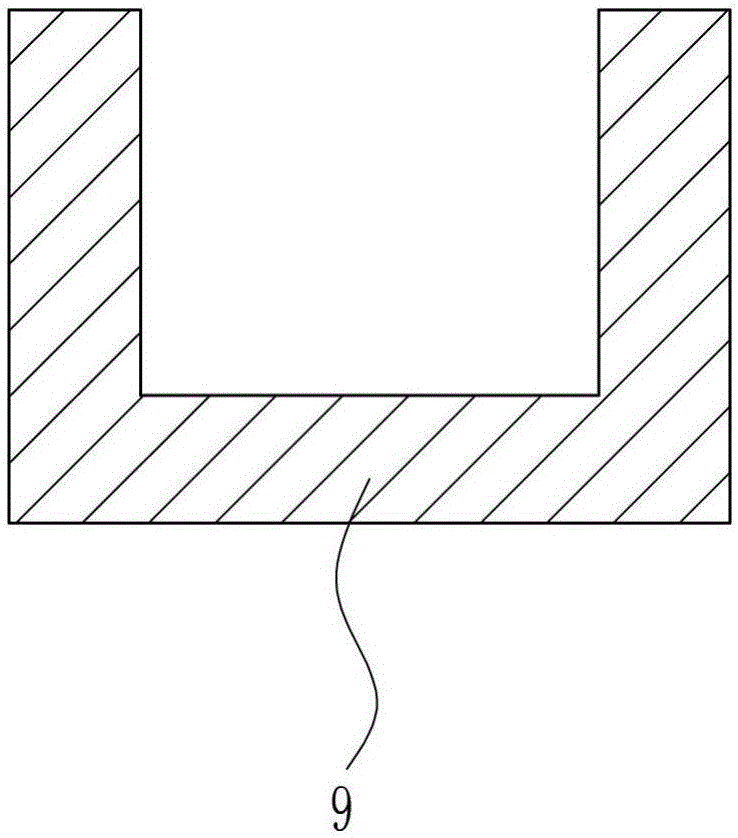

[0029] A kind of strapping equipment for carton production, such as Figure 1-5 As shown, it includes a support plate 1, a workbench 2, a first electric push rod 3, a horizontal plate 4, a second electric push rod 5, a first suction cup 7, a support rod 8, a U-shaped block 9, a fixed plate 10, and a L Type bracket 11, third electric push rod 12, welding head 13, placement box 14 and diaphragm 16, support plates 1 are welded on the left and right sides of the bottom of the workbench 2, and the inner lower parts of the two support plates 1 are connected by bolts The first electric push rod 3 is connected, and the ends of the push rods of the two first electric push rods 3 are provided with a horizontal plate 4, and the middle of the top of the horizontal plate 4 is connected with a second electric push rod 5 by means of bolt connection. The end of the push rod of the rod 5 is provided with a first sucker 7, the middle part of the workbench 2 has a first slot 6, the second electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com